Bearing Manufacturer & Supplier

Specialize in ball bearings, roller bearings, thrust bearings, thin section bearings etc.

You Should Know About Needle Roller Bearings

Needle bearings are roller bearings with cylindrical rollers that are thin and long relative to their diameter. Although the roller has a smaller cross-section, it still has a higher load-bearing capacity. Needle roller bearings are equipped with thin and long rollers (roller diameter D≤5mm, L/D≥2.5, L is the roller length), Therefore, the radial structure is compact. When the inner diameter size and load capacity are the same as other types of bearings, the outer diameter is the smallest. It is especially suitable for support structures with limited radial installation dimensions.

Depending on the use occasion, a needle roller and cage assembly without an inner ring can be selected. At this time, the journal surface and shell hole surface matching the bearing directly serve as the inner and outer rolling surfaces of the bearing. In order to ensure that the load capacity and running performance are the same as those of bearings with rings, the hardness, machining accuracy and surface quality of the raceway surface of the shaft or housing hole should be similar to the raceway of the bearing ring. This kind of bearing can only bear radial load. In addition to those listed in the catalog, bearings that can be used for general engineering, such as: open drawn cup needle roller bearings, closed drawn cup needle roller bearings, needle roller bearings with inner ring and needle roller bearings without inner ring/no inner ring Cageless needle roller bearings, caged and cageless needle roller bearings.

Table of Contents

ToggleTypes of needle roller bearings

Stamped outer ring needle roller bearings

Stamped outer ring needle roller bearings have no inner ring and are available in two types: perforated type and sealed type. The needle roller is in direct contact with the surface of the shaft, so the machining accuracy and heat treatment hardness of the shaft should be the same as the bearing inner ring. Its main feature is that the cross-section height is very low and the load-bearing capacity is high. It is mainly used for bearing configurations that are compact in structure, cheap in price, and the inner hole of the bearing box cannot be used as the raceway of the needle roller cage assembly.

Application: Stamped outer ring needle roller bearings with cages are suitable for high speed and heavy load. They are mostly used in gearboxes of machine tools, automobiles, motorcycles or textile machinery. Cageless stamped ring needle roller bearings are filled with needle rollers and are suitable for oscillating working conditions under heavy loads. Such as the frame of an aircraft, the shaft end of a missile’s main wing, etc.

| Part Number | Seal Type | Bore Dia | Outer Dia | Width | Ring Material | Needle Material | Shaft Mount Type | Temperature Range | Weight |

| 1WC0608 | Open | 6 mm | 10 mm | 8 mm | Steel | Steel | Press Fit | -30° to 110 °C | 2 g |

| 1WC0612 | Open | 6 mm | 10 mm | 12 mm | Steel | Steel | Press Fit | -30° to 110 °C | 3 g |

| 1WC0812 | Open | 8 mm | 14.2 mm | 12 mm | Steel | Steel | Press Fit | -30° to 110 °C | 7 g |

| 1WC0815 | Open | 8 mm | 14.2 mm | 14.5 mm | Steel | Steel | Press Fit | -30° to 110 °C | 8 g |

| 1WC1012 | Open | 10 mm | 16 mm | 12 mm | Steel | Steel | Press Fit | -30° to 110 °C | 8 g |

| 1WC1216 | Open | 12 mm | 18 mm | 16 mm | Steel | Steel | Press Fit | -30° to 110 °C | 12 g |

| EWC0406A | Open | 4 mm | 8 mm | 6 mm | Steel | Steel | Press Fit | -30° to 110 °C | 1 g |

| EWC0406C | Open | 4 mm | 8 mm | 6 mm | Steel | Steel | Press Fit | -30° to 110 °C | 1 g |

| EWC0606XC | Open | 6 mm | 10 mm | 6 mm | Steel | Steel | Press Fit | -30° to 110 °C | 1.4 g |

| EWC0608A | Open | 6 mm | 10 mm | 8 mm | Steel | Steel | Press Fit | -30° to 110 °C | 1.7 g |

| EWC0608C | Open | 6 mm | 10 mm | 8 mm | Steel | Steel | Press Fit | -30° to 110 °C | 1.7 g |

| EWC0608XA | Open | 6 mm | 10 mm | 7.5 mm | Steel | Steel | Press Fit | -30° to 110 °C | 1.7 g |

| EWC0608XC | Open | 6 mm | 10 mm | 7.5 mm | Steel | Steel | Press Fit | -30° to 110 °C | 1.7 g |

| EWC0809A | Open | 8 mm | 12 mm | 9 mm | Steel | Steel | Press Fit | -30° to 110 °C | 2.4 g |

| EWC0809C | Open | 8 mm | 12 mm | 9 mm | Steel | Steel | Press Fit | -30° to 110 °C | 2.4 g |

| EWC0812A | Open | 8 mm | 14.2 mm | 15 mm | Steel | Steel | Press Fit | -30° to 110 °C | 5.8 g |

| EWC0812C | Open | 8 mm | 14.2 mm | 15 mm | Steel | Steel | Press Fit | -30° to 110 °C | 5.8 g |

| EWC1010A | Open | 10 mm | 16 mm | 17 mm | Steel | Steel | Press Fit | -30° to 110 °C | 6 g |

| EWC1010C | Open | 10 mm | 16 mm | 17 mm | Steel | Steel | Press Fit | -30° to 110 °C | 6 g |

| EWC1012A | Open | 10 mm | 16 mm | 17 mm | Steel | Steel | Press Fit | -30° to 110 °C | 6.8 g |

| EWC1012C | Open | 10 mm | 16 mm | 17 mm | Steel | Steel | Press Fit | -30° to 110 °C | 6.8 g |

| HF0306-KF | Open | 3 mm | 6.5 mm | 6 mm | Steel | Steel | Press Fit | -30° to 110 °C | 1 g |

| HF0306-KF-R | Open | 3 mm | 6.5 mm | 6 mm | Steel | Steel | Press Fit | -30° to 110 °C | 1 g |

| HF0406-KF | Open | 4 mm | 8 mm | 6 mm | Steel | Steel | Press Fit | -30° to 110 °C | 1 g |

| HF0406-KF-R | Open | 4 mm | 8 mm | 6 mm | Steel | Steel | Press Fit | -30° to 110 °C | 1 g |

| HF0612 | Open | 6 mm | 10 mm | 12 mm | Steel | Steel | Press Fit | -30° to 110 °C | 3 g |

| HF0612-KF | Open | 6 mm | 10 mm | 12 mm | Steel | Steel | Press Fit | -30° to 110 °C | 3 g |

| HF0612-KF-R | Open | 6 mm | 10 mm | 12 mm | Steel | Steel | Press Fit | -30° to 110 °C | 3 g |

| HF0612-R | Open | 6 mm | 10 mm | 12 mm | Steel | Steel | Press Fit | -30° to 110 °C | 3 g |

| HF0812 | Open | 8 mm | 12 mm | 12 mm | Steel | Steel | Press Fit | -30° to 110 °C | 3.5 g |

| HF0812-KF | Open | 8 mm | 12 mm | 12 mm | Steel | Steel | Press Fit | -30° to 110 °C | 3.5 g |

| HF0812-KF-R | Open | 8 mm | 12 mm | 12 mm | Steel | Steel | Press Fit | -30° to 110 °C | 3.5 g |

| HF0812-R | Open | 8 mm | 12 mm | 12 mm | Steel | Steel | Press Fit | -30° to 110 °C | 3.5 g |

| HF1012 | Open | 10 mm | 14 mm | 12 mm | Steel | Steel | Press Fit | -30° to 110 °C | 4 g |

| HF1012-KF | Open | 10 mm | 14 mm | 12 mm | Steel | Steel | Press Fit | -30° to 110 °C | 4 g |

| HF1216 | Open | 12 mm | 18 mm | 16 mm | Steel | Steel | Press Fit | -30° to 110 °C | 11 g |

| HF1416 | Open | 14 mm | 20 mm | 16 mm | Steel | Steel | Press Fit | -30° to 110 °C | 13 g |

| HF1616 | Open | 16 mm | 22 mm | 16 mm | Steel | Steel | Press Fit | -30° to 110 °C | 14 g |

| HF1816 | Open | 18 mm | 24 mm | 16 mm | Steel | Steel | Press Fit | -30° to 110 °C | 16 g |

| HF2016 | Open | 20 mm | 26 mm | 16 mm | Steel | Steel | Press Fit | -30° to 110 °C | 17 g |

| HF2520 | Open | 25 mm | 32 mm | 20 mm | Steel | Steel | Press Fit | -30° to 110 °C | 30 g |

| HF3020 | Open | 30 mm | 37 mm | 20 mm | Steel | Steel | Press Fit | -30° to 110 °C | 36 g |

| HF3520 | Open | 35 mm | 42 mm | 20 mm | Steel | Steel | Press Fit | -30° to 110 °C | 40 g |

| HFL0308-KF | Open | 3 mm | 6.5 mm | 8 mm | Steel | Steel | Press Fit | -30° to 110 °C | 1.4 g |

| HFL0308-KF-R | Open | 3 mm | 6.5 mm | 8 mm | Steel | Steel | Press Fit | -30° to 110 °C | 1.4 g |

| HFL0408-KF | Open | 4 mm | 8 mm | 8 mm | Steel | Steel | Press Fit | -30° to 110 °C | 1.6 g |

| HFL0408-KF-R | Open | 4 mm | 8 mm | 8 mm | Steel | Steel | Press Fit | -30° to 110 °C | 1.6 g |

| HFL0606-KF-R | Open | 6 mm | 10 mm | 6 mm | Steel | Steel | Press Fit | -30° to 110 °C | 1 g |

| HFL0615 | Open | 6 mm | 10 mm | 15 mm | Steel | Steel | Press Fit | -30° to 110 °C | 4 g |

| HFL0615-KF | Open | 6 mm | 10 mm | 15 mm | Steel | Steel | Press Fit | -30° to 110 °C | 4 g |

| HFL0615-KF-R | Open | 6 mm | 10 mm | 15 mm | Steel | Steel | Press Fit | -30° to 110 °C | 4 g |

| HFL0615-R | Open | 6 mm | 10 mm | 15 mm | Steel | Steel | Press Fit | -30° to 110 °C | 4 g |

| HFL0806-KF-R | Open | 8 mm | 12 mm | 6 mm | Steel | Steel | Press Fit | -30° to 110 °C | 2 g |

| HFL0822 | Open | 8 mm | 12 mm | 22 mm | Steel | Steel | Press Fit | -30° to 110 °C | 7 g |

| HFL0822-KF | Open | 8 mm | 12 mm | 22 mm | Steel | Steel | Press Fit | -30° to 110 °C | 7 g |

| HFL0822-KF-R | Open | 8 mm | 12 mm | 22 mm | Steel | Steel | Press Fit | -30° to 110 °C | 7 g |

| HFL0822-R | Open | 8 mm | 12 mm | 22 mm | Steel | Steel | Press Fit | -30° to 110 °C | 7 g |

| HFL1022 | Open | 10 mm | 14 mm | 22 mm | Steel | Steel | Press Fit | -30° to 110 °C | 8 g |

| HFL1226 | Open | 12 mm | 18 mm | 26 mm | Steel | Steel | Press Fit | -30° to 110 °C | 18 g |

| HFL1426 | Open | 14 mm | 20 mm | 26 mm | Steel | Steel | Press Fit | -30° to 110 °C | 20 g |

| HFL1626 | Open | 16 mm | 22 mm | 26 mm | Steel | Steel | Press Fit | -30° to 110 °C | 22 g |

| HFL1826 | Open | 18 mm | 24 mm | 26 mm | Steel | Steel | Press Fit | -30° to 110 °C | 25 g |

| HFL2026 | Open | 20 mm | 26 mm | 26 mm | Steel | Steel | Press Fit | -30° to 110 °C | 27 g |

| HFL2530 | Open | 25 mm | 32 mm | 30 mm | Steel | Steel | Press Fit | -30° to 110 °C | 44 g |

| HFL3030 | Open | 30 mm | 37 mm | 30 mm | Steel | Steel | Press Fit | -30° to 110 °C | 51 g |

| HFL3530 | Open | 35 mm | 42 mm | 30 mm | Steel | Steel | Press Fit | -30° to 110 °C | 58 g |

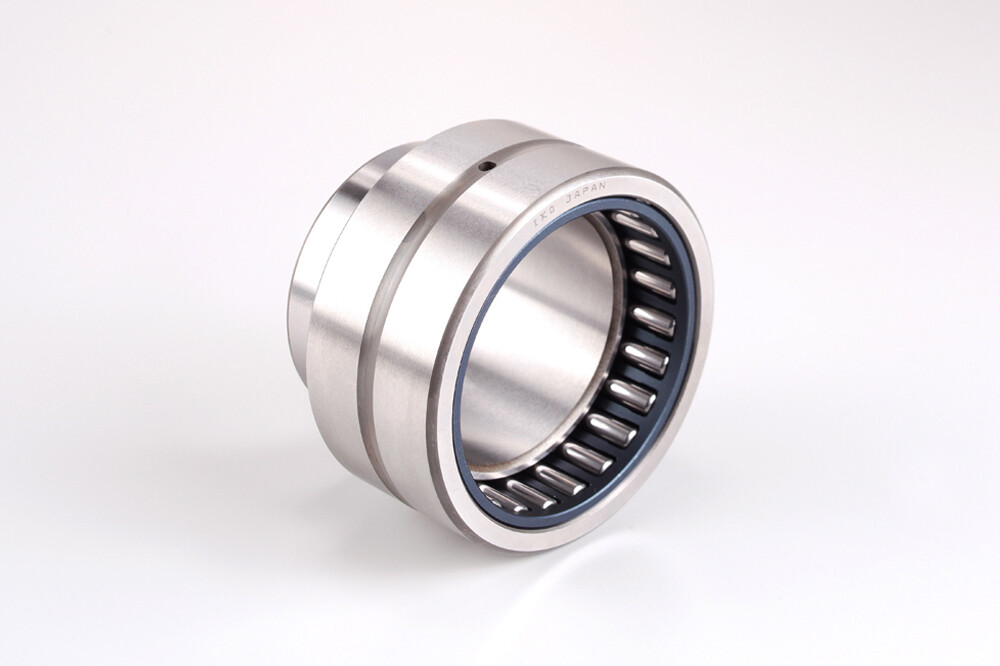

Solid ring needle roller bearings.

Solid ring needle roller bearings are composed of one or two rings and a needle roller group with a cage. Depending on the application, it can be divided into bearings with or without inner rings. NA and NKI type bearings without inner rings are RNA and NK type needle roller bearings. This kind of bearing has no inner ring and is suitable for support structures with limited radial installation size. The journal matching the bearing directly serves as the rolling surface. As the raceway surface, the shaft must be hardened and ground, and only when it is processed to appropriate size and shape accuracy can the entire set of needle roller bearings have a higher service life and operating accuracy.

Application: Mostly used in machine tools and automobile gearboxes. Its advantages are small radial cross-section size and large radial load. Standard solid ring needle roller bearings have cages, so the rotation speed is high and can adapt to the requirements of machine tools and gearboxes.

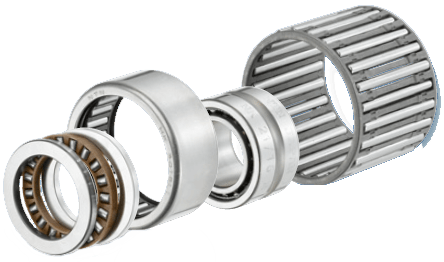

Combined needle roller bearing

The combined needle roller bearing is a bearing unit composed of a radial needle roller bearing and a thrust bearing component. It has a compact structure, small size, and high rotation accuracy. It can withstand high radial loads and a certain axial load at the same time. The needle roller and cage assembly is a separate bearing element. Each needle is precisely guided and secured by a cage. It has the highest load-bearing capacity and high rigidity design in the smallest structure and space. The large distance between the two guide surfaces of the cage ensures precise guidance of the needle roller and cage assembly. Needle roller cage assemblies are suitable when the shaft and housing bore are used as raceways.

Thrust needle roller bearings consist of a thrust cage assembly with needle rollers or cylindrical rollers or balls and a thrust washer. The needle rollers and cylindrical rollers are held and guided by thrust cages. When used with different series of DF thrust bearing washers, many different combinations of bearing configurations are available.

The needle roller and cage assembly is actually a needle roller bearing without a ferrule. Scope of application: It is mostly used in the large and small ends of connecting rods in automobiles and motorcycles. Since the temperature inside the air box rises, the bearings must withstand high temperatures.

| Part Number | Bearing Type | Bore Dia | Outer Dia | Width | Needle Material | Dynamic Radial Load | Static Radial Load | Max Speed (X1000 rpm) | Weight |

| C060806 | Needle | 0.375″ | 0.5″ | 0.375″ | Steel | 899 lbf | 944 lbf | 30 | 2.5 g |

| C081008 | Needle | 0.5″ | 0.625″ | 0.5″ | Steel | 1484 lbf | 1956 lbf | 26 | 4.2 g |

| C091108 | Needle | 0.5625″ | 0.688″ | 0.625″ | Steel | 1641 lbf | 2293 lbf | 25 | 5.9 g |

| C091110 | Needle | 0.5625″ | 0.688″ | 0.625″ | Steel | 2203 lbf | 3372 lbf | 25 | 5.9 g |

| C101208 | Needle | 0.625″ | 0.75″ | 0.5″ | Steel | 1843 lbf | 2765 lbf | 24 | 5.2 g |

| C121616 | Needle | 0.75″ | 1″ | 1″ | Steel | 562 lbf | 7756 lbf | 21.2 | 26.4 g |

| C141816 | Needle | 0.875″ | 1.125″ | 1″ | Steel | 6519 lbf | 9779 lbf | 19.3 | 30.1 g |

| C162112 | Needle | 1″ | 1.313″ | 0.75″ | Steel | 6407 lbf | 8543 lbf | 16.7 | 32.6 g |

| C162116 | Needle | 1″ | 1.313″ | 1″ | Steel | 8206 lbf | 11915 lbf | 16.7 | 43.5 g |

| C182416 | Needle | 1.125″ | 1.5″ | 1″ | Steel | 9667 lbf | 13489 lbf | 14.7 | 59.3 g |

| C182420 | Needle | 1.125″ | 1.5″ | 1.25″ | Steel | 1169 lbf | 17085 lbf | 15 | 74.1 g |

| C202616 | Needle | 1.25″ | 1.625″ | 1″ | Steel | 10116 lbf | 14613 lbf | 13.4 | 64.9 g |

| C202812 | Needle | 1.25″ | 1.75″ | 0.75″ | Steel | 9779 lbf | 1169 lbf | 12.9 | 67.8 g |

| C222820 | Needle | 1.375″ | 1.75″ | 1.25″ | Steel | 12589 lbf | 19783 lbf | 12.3 | 88.2 g |

| C243016 | Needle | 1.5″ | 1.875″ | 1″ | Steel | 10791 lbf | 16636 lbf | 11.4 | 76.2 g |

| C243024 | Needle | 1.5″ | 1.875″ | 1.5″ | Steel | 15287 lbf | 26078 lbf | 11.4 | 114.3 g |

| C364216 | Needle | 2.25″ | 2.625″ | 1″ | Steel | 13489 lbf | 25179 lbf | 7.9 | 110.1 g |

| C404616 | Needle | 2.5″ | 2.875″ | 1″ | Steel | 13938 lbf | 27202 lbf | 7.2 | 121.4 g |

| C485424 | Needle | 3″ | 3.375″ | 1.5″ | Steel | 21132 lbf | 49233 lbf | 6.1 | 216 g |

| K100X107X21 | Needle | 100 mm | 107 mm | 21 mm | Steel | 10791 lbf | 28551 lbf | 4.8 | 120 g |

| K100X108X27 | Needle | 100 mm | 108 mm | 27 mm | Steel | 12814 lbf | 32148 lbf | 4.7 | 185 g |

| K100X108X30 | Needle | 100 mm | 108 mm | 30 mm | Steel | 15961 lbf | 42264 lbf | 4.7 | 180 g |

| K105X112X21 | Needle | 105 mm | 112 mm | 21 mm | Steel | 10678 lbf | 28551 lbf | 4.5 | 129 g |

| K10X13X10-TV | Needle | 10 mm | 13 mm | 10 mm | Steel | 1068 lbf | 1236 lbf | 29.5 | 1.6 g |

| K10X13X13-TV | Needle | 10 mm | 13 mm | 13 mm | Steel | 1394 lbf | 1754 lbf | 29.5 | 2.3 g |

| K10X13X16-TV | Needle | 10 mm | 13 mm | 16 mm | Steel | 1596 lbf | 2091 lbf | 29.5 | 2.9 g |

| K10X14X10-TV | Needle | 10 mm | 14 mm | 10 mm | Steel | 1304 lbf | 1349 lbf | 29 | 2.5 g |

| K10X14X13-TV | Needle | 10 mm | 14 mm | 13 mm | Steel | 1686 lbf | 1888 lbf | 29 | 4.6 g |

| K10X16X12-TV | Needle | 10 mm | 16 mm | 12 mm | Steel | 1821 lbf | 1619 lbf | 27.5 | 5.5 g |

| K110X117X24 | Needle | 110 mm | 117 mm | 24 mm | Steel | 12589 lbf | 3552 lbf | 4.3 | 172 g |

| K110X118X30 | Needle | 110 mm | 118 mm | 30 mm | Steel | 17535 lbf | 49233 lbf | 4.3 | 217 g |

| K115X123X27 | Needle | 115 mm | 123 mm | 27 mm | Steel | 14163 lbf | 38218 lbf | 4.1 | 200 g |

| K120X127X24 | Needle | 120 mm | 127 mm | 24 mm | Steel | 13264 lbf | 39117 lbf | 4 | 165 g |

| K125X133X35 | Needle | 125 mm | 133 mm | 35 mm | Steel | 19334 lbf | 5845 lbf | 3.8 | 275 g |

| K12X15X10-TV | Needle | 12 mm | 15 mm | 10 mm | Steel | 1102 lbf | 1371 lbf | 27 | 2.9 g |

| K12X15X13-TV | Needle | 12 mm | 15 mm | 13 mm | Steel | 1439 lbf | 1911 lbf | 27 | 2.3 g |

| K12X16X13-TV | Needle | 12 mm | 16 mm | 13 mm | Steel | 1798 lbf | 2113 lbf | 26.5 | 3.6 g |

| K12X17X13-TV | Needle | 12 mm | 17 mm | 13 mm | Steel | 2158 lbf | 2338 lbf | 26.5 | 4.9 g |

| K12X18X12-TV | Needle | 12 mm | 18 mm | 12 mm | Steel | 2248 lbf | 2226 lbf | 26 | 6 g |

| K130X137X24 | Needle | 130 mm | 137 mm | 24 mm | Steel | 13713 lbf | 41814 lbf | 3.7 | 170 g |

| K135X143X35 | Needle | 135 mm | 143 mm | 35 mm | Steel | 20458 lbf | 65195 lbf | 3.6 | 300 g |

| K145X153X26 | Needle | 145 mm | 153 mm | 26 mm | Steel | 16636 lbf | 50582 lbf | 3.3 | 262 g |

| K14X18X10 | Needle | 14 mm | 18 mm | 10 mm | Steel | 1596 lbf | 1911 lbf | 25 | 4 g |

| K14X18X13 | Needle | 14 mm | 18 mm | 13 mm | Steel | 1843 lbf | 2271 lbf | 25 | 6.5 g |

| K14X18X15-TV | Needle | 14 mm | 18 mm | 15 mm | Steel | 2136 lbf | 2765 lbf | 25 | 5 g |

| K14X18X17 | Needle | 14 mm | 18 mm | 17 mm | Steel | 2428 lbf | 3237 lbf | 25 | 8 g |

| K14X20X12 | Needle | 14 mm | 20 mm | 12 mm | Steel | 2316 lbf | 2383 lbf | 24.3 | 8.5 g |

| K150X160X46 | Needle | 150 mm | 160 mm | 46 mm | Steel | 33047 lbf | 10566 lbf | 3.2 | 570 g |

| K155X163X26 | Needle | 155 mm | 163 mm | 26 mm | Steel | 16861 lbf | 53055 lbf | 3.1 | 265 g |

| K15X18X17-TV | Needle | 15 mm | 18 mm | 17 mm | Steel | 1798 lbf | 272 lbf | 24.6 | 4.6 g |

| K15X19X10 | Needle | 15 mm | 19 mm | 10 mm | Steel | 1686 lbf | 2068 lbf | 24.3 | 5 g |

| K15X19X13 | Needle | 15 mm | 19 mm | 13 mm | Steel | 1911 lbf | 245 lbf | 24.3 | 7 g |

| K15X19X17 | Needle | 15 mm | 19 mm | 17 mm | Steel | 254 lbf | 3507 lbf | 24.3 | 9.5 g |

| K15X20X13 | Needle | 15 mm | 20 mm | 13 mm | Steel | 2226 lbf | 2585 lbf | 23.9 | 7 g |

| K15X21X15 | Needle | 15 mm | 21 mm | 15 mm | Steel | 3215 lbf | 3687 lbf | 23.6 | 11 g |

| K15X21X21 | Needle | 15 mm | 21 mm | 21 mm | Steel | 4361 lbf | 5463 lbf | 23.6 | 17 g |

| K160X170X46 | Needle | 160 mm | 170 mm | 46 mm | Steel | 34171 lbf | 114653 lbf | 3 | 550 g |

| K165X173X26 | Needle | 165 mm | 173 mm | 26 mm | Steel | 1821 lbf | 59574 lbf | 2.9 | 320 g |

| K16X20X10 | Needle | 16 mm | 20 mm | 10 mm | Steel | 1754 lbf | 2226 lbf | 23.6 | 5.5 g |

| K16X20X13 | Needle | 16 mm | 20 mm | 13 mm | Steel | 2001 lbf | 2653 lbf | 23.6 | 7.5 g |

| K16X20X17 | Needle | 16 mm | 20 mm | 17 mm | Steel | 263 lbf | 3777 lbf | 23.6 | 10 g |

| K16X22X12 | Needle | 16 mm | 22 mm | 12 mm | Steel | 2585 lbf | 281 lbf | 22.9 | 10 g |

| K16X22X16 | Needle | 16 mm | 22 mm | 16 mm | Steel | 3327 lbf | 3934 lbf | 22.9 | 12 g |

| K16X22X20 | Needle | 16 mm | 22 mm | 20 mm | Steel | 4114 lbf | 5126 lbf | 22.9 | 17 g |

| K16X24X20 | Needle | 16 mm | 24 mm | 20 mm | Steel | 4811 lbf | 5283 lbf | 22.4 | 22 g |

| K175X183X32 | Needle | 175 mm | 183 mm | 32 mm | Steel | 22256 lbf | 78683 lbf | 2.8 | 400 g |

| K17X21X10 | Needle | 17 mm | 21 mm | 10 mm | Steel | 1821 lbf | 2383 lbf | 22.9 | 5.5 g |

| K17X21X13 | Needle | 17 mm | 21 mm | 13 mm | Steel | 2338 lbf | 3282 lbf | 22.9 | 6.5 g |

| K17X21X17 | Needle | 17 mm | 21 mm | 17 mm | Steel | 2743 lbf | 4024 lbf | 22.9 | 9.5 g |

| K185X195X37 | Needle | 185 mm | 195 mm | 37 mm | Steel | 28776 lbf | 95544 lbf | 2.6 | 607 g |

| K18X22X10 | Needle | 18 mm | 22 mm | 10 mm | Steel | 1888 lbf | 254 lbf | 22.4 | 6 g |

| K18X22X13 | Needle | 18 mm | 22 mm | 13 mm | Steel | 2068 lbf | 2855 lbf | 22.4 | 8 g |

| K18X22X17 | Needle | 18 mm | 22 mm | 17 mm | Steel | 272 lbf | 4047 lbf | 22.4 | 11 g |

| K18X24X12 | Needle | 18 mm | 24 mm | 12 mm | Steel | 2878 lbf | 335 lbf | 21.8 | 12 g |

| K18X24X13 | Needle | 18 mm | 24 mm | 13 mm | Steel | 2945 lbf | 344 lbf | 21.8 | 13 g |

| K18X24X20 | Needle | 18 mm | 24 mm | 20 mm | Steel | 4541 lbf | 607 lbf | 21.8 | 18 g |

| K18X25X22 | Needle | 18 mm | 25 mm | 22 mm | Steel | 5193 lbf | 6519 lbf | 21.6 | 23 g |

| K195X205X37 | Needle | 195 mm | 205 mm | 37 mm | Steel | 299 lbf | 101164 lbf | 2.5 | 620 g |

| K19x23x13 | Needle | 19 mm | 23 mm | 13 mm | Steel | 2136 lbf | 3035 lbf | 21.8 | 8 g |

| K19x23x17 | Needle | 19 mm | 23 mm | 17 mm | Steel | 281 lbf | 4316 lbf | 21.8 | 11 g |

| K20X24X10 | Needle | 20 mm | 24 mm | 10 mm | Steel | 2001 lbf | 2833 lbf | 21.3 | 6.5 g |

| K20X24X13 | Needle | 20 mm | 24 mm | 13 mm | Steel | 2203 lbf | 3215 lbf | 21.3 | 9 g |

| K20X24X17 | Needle | 20 mm | 24 mm | 17 mm | Steel | 29 lbf | 4586 lbf | 21.3 | 12 g |

| K20X26X12 | Needle | 20 mm | 26 mm | 12 mm | Steel | 3012 lbf | 3642 lbf | 20.9 | 11 g |

| K20X26X13 | Needle | 20 mm | 26 mm | 13 mm | Steel | 3237 lbf | 4024 lbf | 20.9 | 12 g |

| K20X26X17 | Needle | 20 mm | 26 mm | 17 mm | Steel | 4316 lbf | 5845 lbf | 20.9 | 16 g |

| K20X26X20 | Needle | 20 mm | 26 mm | 20 mm | Steel | 4743 lbf | 6519 lbf | 20.9 | 19 g |

| K20X28X16 | Needle | 20 mm | 28 mm | 16 mm | Steel | 4451 lbf | 5036 lbf | 20.4 | 20 g |

| K20X28X20 | Needle | 20 mm | 28 mm | 20 mm | Steel | 5373 lbf | 6407 lbf | 20.4 | 27 g |

| K20X28X25 | Needle | 20 mm | 28 mm | 25 mm | Steel | 6857 lbf | 8768 lbf | 20.4 | 32 g |

| K20X30X30 | Needle | 20 mm | 30 mm | 30 mm | Steel | 7981 lbf | 933 lbf | 19.6 | 49 g |

| K210X220X42 | Needle | 210 mm | 220 mm | 42 mm | Steel | 34621 lbf | 125893 lbf | 2.3 | 740 g |

| K21X25X13 | Needle | 21 mm | 25 mm | 13 mm | Steel | 2271 lbf | 3395 lbf | 20.9 | 9 g |

| K220X230X42 | Needle | 220 mm | 230 mm | 42 mm | Steel | 3552 lbf | 132637 lbf | 2.2 | 790 g |

| K22X26X10 | Needle | 22 mm | 26 mm | 10 mm | Steel | 2046 lbf | 3012 lbf | 20.4 | 7.5 g |

| K22X26X13 | Needle | 22 mm | 26 mm | 13 mm | Steel | 2338 lbf | 3574 lbf | 20.4 | 9.5 g |

| K22X26X17 | Needle | 22 mm | 26 mm | 17 mm | Steel | 308 lbf | 5103 lbf | 20.4 | 12 g |

| K22X28X17 | Needle | 22 mm | 28 mm | 17 mm | Steel | 4361 lbf | 607 lbf | 19.6 | 18 g |

| K22X29X16 | Needle | 22 mm | 29 mm | 16 mm | Steel | 4496 lbf | 5733 lbf | 19.2 | 16 g |

| K22X30X15-TV | Needle | 22 mm | 30 mm | 15 mm | Steel | 4519 lbf | 5261 lbf | 18.8 | 18 g |

About needle roller combination bearings

The so-called needle roller combination bearing refers to a bearing that is a combination of a needle roller bearing and other types of bearings. According to the difference of the combined bearings, the needle roller combination bearing is divided into NKX type, NKXR type, NKIA type, NKIB type, AXN type and ARN type, the detailed information of various types of needle roller combination bearings are as follows:

NKX (needle roller combined thrust ball bearing).

Needle roller bearings bear radial loads, and thrust ball bearings bear axial loads. They are suitable for bearing lighter axial loads and can rotate at high speeds. Common codes are such as NKX20T2Z, where T2 stands for resin cage and Z stands for dust cover. , if there is no suffix, it is an iron cage.

NKXR (needle roller combined thrust roller bearing)

The shape of the NKXR type is basically the same as the NKX type. The balls are replaced by rollers, which can withstand higher axial loads. The rear code is the same as the NKX type.

| Part Number | Bore Dia | Outer Dia | Thickness | Needle Material | Dynamic Thrust Load | Static Thrust Load | Max Speed (X1000 rpm) |

| AXK0414-TV | 4 mm | 14 mm | 2 mm | Steel | 989 lbf | 1798 lbf | 21.5 |

| AXK0515-TV | 5 mm | 15 mm | 2 mm | Steel | 1068 lbf | 2068 lbf | 20.6 |

| AXK0619-TV | 6 mm | 19 mm | 2 mm | Steel | 1529 lbf | 3485 lbf | 18.9 |

| AXK0821-TV | 8 mm | 21 mm | 2 mm | Steel | 1754 lbf | 4361 lbf | 17.8 |

| AXK100135 | 100 mm | 135 mm | 4 mm | Steel | 20458 lbf | 125893 lbf | 2.4 |

| AXK1024 | 10 mm | 24 mm | 2 mm | Steel | 2068 lbf | 5733 lbf | 16.9 |

| AXK110145 | 110 mm | 145 mm | 4 mm | Steel | 21806 lbf | 139382 lbf | 2.2 |

| AXK120155 | 120 mm | 155 mm | 4 mm | Steel | 22931 lbf | 15287 lbf | 2.1 |

| AXK1226 | 12 mm | 26 mm | 2 mm | Steel | 2226 lbf | 6519 lbf | 15.2 |

| AXK130170 | 130 mm | 170 mm | 5 mm | Steel | 299 lbf | 18884 lbf | 1.9 |

| AXK140180 | 140 mm | 180 mm | 5 mm | Steel | 31024 lbf | 202328 lbf | 1.8 |

| AXK150190 | 150 mm | 190 mm | 5 mm | Steel | 32148 lbf | 215817 lbf | 1.7 |

| AXK1528 | 15 mm | 28 mm | 2 mm | Steel | 254 lbf | 8093 lbf | 13.2 |

| AXK160200 | 160 mm | 200 mm | 5 mm | Steel | 33272 lbf | 229305 lbf | 1.6 |

| AXK1730 | 17 mm | 30 mm | 2 mm | Steel | 2675 lbf | 888 lbf | 12.1 |

| AXK2035 | 20 mm | 35 mm | 2 mm | Steel | 2945 lbf | 10454 lbf | 10.5 |

| AXK2542 | 25 mm | 42 mm | 2 mm | Steel | 3305 lbf | 13039 lbf | 8.4 |

| AXK3047 | 30 mm | 47 mm | 2 mm | Steel | 3664 lbf | 15737 lbf | 7.3 |

| AXK3552 | 35 mm | 52 mm | 2 mm | Steel | 4002 lbf | 1821 lbf | 6.5 |

| AXK4060 | 40 mm | 60 mm | 3 mm | Steel | 6295 lbf | 25628 lbf | 5.6 |

| AXK4565 | 45 mm | 65 mm | 3 mm | Steel | 6744 lbf | 28776 lbf | 5.1 |

| AXK5070 | 50 mm | 70 mm | 3 mm | Steel | 7194 lbf | 32148 lbf | 4.7 |

| AXK5578 | 55 mm | 78 mm | 3 mm | Steel | 8543 lbf | 41814 lbf | 4.3 |

| AXK6085 | 60 mm | 85 mm | 3 mm | Steel | 10004 lbf | 52605 lbf | 3.9 |

| AXK6590 | 65 mm | 90 mm | 3 mm | Steel | 10454 lbf | 57326 lbf | 3.7 |

| AXK7095 | 70 mm | 95 mm | 4 mm | Steel | 1214 lbf | 57326 lbf | 3.5 |

| AXK75100 | 75 mm | 100 mm | 4 mm | Steel | 12364 lbf | 59574 lbf | 3.3 |

| AXK80105 | 80 mm | 105 mm | 4 mm | Steel | 12589 lbf | 62947 lbf | 3.1 |

| AXK85110 | 85 mm | 110 mm | 4 mm | Steel | 13039 lbf | 65195 lbf | 3 |

| AXK90120 | 90 mm | 120 mm | 4 mm | Steel | 16411 lbf | 91048 lbf | 2.7 |

| AXW10 | 10 mm | 27 mm | 3.2 mm | Steel | 2068 lbf | 5733 lbf | 16.9 |

| AXW12 | 12 mm | 29 mm | 3.2 mm | Steel | 2226 lbf | 6519 lbf | 15.2 |

| AXW15 | 15 mm | 31 mm | 3.2 mm | Steel | 254 lbf | 8093 lbf | 13.2 |

| AXW17 | 17 mm | 33 mm | 3.2 mm | Steel | 2675 lbf | 888 lbf | 12.1 |

| AXW20 | 20 mm | 38 mm | 3.2 mm | Steel | 2945 lbf | 10454 lbf | 10.5 |

| AXW25 | 25 mm | 45 mm | 3.2 mm | Steel | 3305 lbf | 13039 lbf | 8.4 |

| AXW30 | 30 mm | 50 mm | 3.2 mm | Steel | 3664 lbf | 15737 lbf | 7.3 |

| AXW35 | 35 mm | 55 mm | 3.2 mm | Steel | 4002 lbf | 1821 lbf | 6.5 |

| AXW40 | 40 mm | 63 mm | 4.2 mm | Steel | 6295 lbf | 25628 lbf | 5.6 |

| AXW45 | 45 mm | 68 mm | 4.2 mm | Steel | 6744 lbf | 28776 lbf | 5.1 |

| AXW50 | 50 mm | 73 mm | 4.2 mm | Steel | 7194 lbf | 32148 lbf | 4.7 |

| TC1018 | 0.625″ | 1.125″ | 0.078″ | Steel | 2158 lbf | 6632 lbf | 13 |

| TC1220 | 0.75″ | 1.25″ | 0.078″ | Steel | 2405 lbf | 7981 lbf | 11.3 |

| TC1423 | 0.875″ | 1.438″ | 0.078″ | Steel | 2878 lbf | 10454 lbf | 9.8 |

| TC1427 | 0.875″ | 1.688″ | 0.078″ | Steel | 4406 lbf | 18659 lbf | 8.9 |

| TC1625 | 1″ | 1.563″ | 0.078″ | Steel | 3125 lbf | 1214 lbf | 8.9 |

| TC1726 | 1.0625″ | 1.625″ | 0.078″ | Steel | 3395 lbf | 13713 lbf | 8.4 |

| TC1828 | 1.125″ | 1.75″ | 0.078″ | Steel | 3844 lbf | 16411 lbf | 7.9 |

| TC2031 | 1.25″ | 1.938″ | 0.078″ | Steel | 4474 lbf | 20458 lbf | 7.1 |

| TC2233 | 1.375″ | 2.063″ | 0.078″ | Steel | 4564 lbf | 21582 lbf | 6.6 |

| TC2435 | 1.5″ | 2.188″ | 0.078″ | Steel | 4833 lbf | 2383 lbf | 6.1 |

| TC2840 | 1.75″ | 2.5″ | 0.078″ | Steel | 5598 lbf | 30124 lbf | 5.2 |

| TC3244 | 2″ | 2.75″ | 0.078″ | Steel | 562 lbf | 32597 lbf | 4.1 |

| TC3648 | 2.25″ | 3″ | 0.078″ | Steel | 607 lbf | 3507 lbf | 4.4 |

| TC4052 | 2.5″ | 3.25″ | 0.078″ | Steel | 6182 lbf | 37768 lbf | 4 |

| TC411 | 0.25″ | 0.688″ | 0.078″ | Steel | 1371 lbf | 299 lbf | 19.2 |

| TC4860 | 3″ | 3.75″ | 0.078″ | Steel | 6632 lbf | 42714 lbf | 3.4 |

| TC512 | 0.3125″ | 0.75″ | 0.078″ | Steel | 1551 lbf | 3642 lbf | 18 |

| TC5266 | 3.25″ | 4.125″ | 0.126″ | Steel | 10903 lbf | 60698 lbf | 2.6 |

| TC613 | 0.375″ | 0.813″ | 0.078″ | Steel | 1596 lbf | 3979 lbf | 17.4 |

| TC815 | 0.5″ | 0.938″ | 0.078″ | Steel | 1911 lbf | 5305 lbf | 15.8 |

NKIA (needle roller combination angular contact ball bearing).

The combined bearing composed of needle roller bearings and angular contact ball bearings can withstand the unidirectional axial load determined by the angular contact ball bearing, and is suitable for high-speed rotation and light load scenarios.

NKIB (needle roller combination three-point contact ball bearing)

The combined bearing composed of needle roller bearing and three-point contact ball bearing has the same application range as NKIA type and can withstand bidirectional axial load.

AXN (needle roller combination bidirectional thrust needle roller bearing).

A combination bearing of a needle roller bearing and a bidirectional thrust needle roller is a support bearing for precision ball screws and can withstand bidirectional axial loads.

ARN (needle roller combination two-way thrust roller bearing).

It is basically the same as the AXN type, but in comparison, the ARN type has a higher axial load capacity.

Advantages and Disadvantages of Needle Roller Bearings

Needle roller bearings, favored by the machinery manufacturing industry, are a type of bearing with slender rollers and a small cross-sectional area. At present, needle roller bearings are mainly suitable for support structure products with small radial installation dimensions. Next, let’s briefly introduce the main advantages and disadvantages of needle roller bearings with outstanding quality and special purposes.

Compact radial structure

At present, as mechanical products have developed to a very refined level, many mechanical products have detailed requirements for the bearing products used due to actual needs. Needle roller bearings that meet customers are a special kind of needle roller bearings developed on this basis. Bearing products, needle roller bearings have the characteristics of very compact radial structure, and can exert better functional advantages in mechanical products with smaller radial space.

Larger load intensity

Because bearing products require long-term operation in actual use, there are strict requirements for their load strength. At present, many mechanical products are beginning to develop in the direction of miniaturization and precision, and there are very strict requirements for the structure and size of bearing products. Needle roller bearings are cost-effective and quality-guaranteed products because they are made of high-quality materials and their structure is extremely suitable for small spaces. In the same radial size, the load capacity of needle roller bearings is its advantage over other products.

Long service life

Needle roller bearing products are designed with the needs of many mechanical products in mind. At the same time, in order to enhance their strength and load capacity, manufacturers use extremely hard alloy materials when producing needle roller bearings. This makes needle roller bearings an ideal choice for machinery. The product can achieve a long service life and has a very high cost-effective advantage.

Conclusion

The advantages of needle roller bearings: small friction resistance, low power consumption, high mechanical efficiency, and easy starting. The dimensions are standardized, interchangeable, easy to install and disassemble, and easy to maintain. Compact structure, light weight and smaller axial size. High precision, high rotation speed, small wear and long service life. Some bearings have self-aligning performance and are suitable for mass production. They have stable and reliable quality and high production efficiency. The transmission friction torque is much lower than that of hydrodynamic bearings, so the friction temperature rise and power consumption are lower; the starting friction torque is only slightly higher than the rotational friction torque; the sensitivity of bearing deformation to load changes is smaller than that of hydrodynamic bearings; only a small amount is needed The lubricant can operate normally and can provide lubricant for a long time during operation; the axial size is smaller than that of traditional hydrodynamic bearings; it can withstand radial and thrust combined loads at the same time; in a large load-speed range, the unique design Excellent performance can be obtained; bearing performance is relatively insensitive to fluctuations in load, speed and operating speed.

Disadvantages of needle roller bearings: they are noisy, the structure of the bearing seat is relatively complex, and the cost is high. Even if the bearings are well lubricated, installed correctly, dust-proof and moisture-proof, and operate normally, they will eventually fail due to fatigue of the rolling contact surface.

Needle roller bearing products are currently widely used in miniaturized mechanical products, which can effectively improve the quality and performance of mechanical products. Taken together, the needle roller bearing product with a single range of use not only has a compact radial structure, but its load intensity per unit area is also far higher than that of other bearing products, and this needle roller bearing product with excellent quality and stable performance also has The advantages of extremely long service life are the main advantages of this unique needle roller bearing for special applications in this radial structure.

Needle roller bearings VS ball bearings

Ball bearings are a commonly used precision bearing with characteristics of light load and high speed. Its appearance is spherical and consists of an inner ring, an outer ring, a ball and a cage. The following is an analysis of the advantages and disadvantages of ball bearings:

Advantages of ball bearings:

1. High speed: The structure of the ball bearing gear makes its friction coefficient relatively small, so it can withstand high-speed rotation.

2. Low noise: There is no contact surface between the wheels of ball bearings. The combination of these factors makes ball bearings have low friction, low noise and long life.

3. High precision: Because the inner ring, outer ring and spherical body of the ball bearing are processed with high precision, its precision is very high.

4. Suitable for bearing radial and axial loads.

Disadvantages of Ball bearing

1. Low load carrying capacity: The radius of the ball bearing is very small, so the load it can carry is also small.

2. Accuracy is affected by contamination: Ball bearings have high accuracy, and impurities such as particles or dust will affect their accuracy and affect the free rotation of the wheel.

3. Vibration and impact loads can cause wheels to shatter.

Ball bearings and needle roller bearings each have their own advantages and disadvantages. When choosing a bearing type, you need to choose based on your requirements for load, speed, accuracy and other factors. If you need to bear a smaller load and require high-speed operation, it is better to choose a ball bearing. If you need to bear a larger load and have strong vibration resistance, it is appropriate to choose a needle roller bearing. By clearly understanding and evaluating their characteristics, the correct bearings can be selected effectively, thus ensuring the stability and performance of the equipment.

Needle roller bearings VS tapered roller bearings

Needle roller bearings (NK, NKS, RNA49, RNA48, NKL, NKLS, NA49, NA48, RNA69, NA69, RNA49…RS, RNA49..2RS, NA49..RS, NA49..2RS, RNAO, NAO) Compact structure, The radial size is small, the load capacity is large, and it can withstand large radial loads. This type of bearing has a variety of structures and size series. The assembled G2 grade needle rollers have a batch diameter variation within 2um. Except for the full complement needle roller bearings, they all use high-performance cages to correctly guide the parallel axis of the needle rollers. .

The fundamental difference: the rolling elements of tapered roller bearings are tapered rollers; the rolling elements of needle roller bearings are needle rollers; the structures are different, the types are different, the bearing capacity is different, the speed ratio is different, and the load is different. The materials are different and the places of use are different. Essential difference: the rolling elements of tapered roller bearings are tapered rollers; the rolling elements of needle roller bearings are fibrous rollers;

The above essential differences determine that the structure of tapered roller bearings is larger than that of needle roller bearings. In addition to radial loads, tapered rollers can also bear axial loads, while needle roller bearings can only bear radial loads; tapered roller bearings can only bear radial loads. Roller bearings are divided into single row, double row and multi-row, each of which is used in different environments and places;

Tapered roller bearings have a higher operating speed than needle roller bearings; tapered roller bearings are generally made of high-quality bearing steel and special steel; while thick-walled needle roller bearings are stamped from thick steel plates In other words, these two types of bearings are not the same type of bearings. There are so many differences that they pale in comparison. Needle roller bearings are composed of thin and long needle rollers and cages.

Needle roller bearings VS cylindrical roller bearings

Cylindrical roller bearings have linear contact with the raceway. Therefore, the load capacity is large. According to the ribs of their rings, they can be divided into single-row cylindrical roller bearings such as NU type, NJ type, NUP type, N type, and NF type, and double-row cylindrical roller bearings such as NNU type and NN type. Cylindrical roller bearings with ribless rings, whose inner and outer rings can move relative to each other in the axial direction, are often used at the free end of equipment. There is a double rib on one side of the inner ring or outer ring and a single rib on the other side, which can withstand a certain unidirectional axial load. The cage is mostly made of steel plate stamping or copper alloy turning. A small number of them use polyamide molded cages.

The main differences between cylindrical roller bearings and needle roller bearings:

1. The rolling elements are different. The rolling elements of needle roller bearings are thinner and longer;

2. The spatial structure of needle roller bearings is relatively small;

3. Needle roller bearings can only bear radial force; but cylindrical rollers can also bear a certain axial force;

4. Cylindrical roller bearings are available in single row, double row and multi-row, and can be used in environments;

5. Needle roller bearings can only be used at low-speed working speeds;

6. Thin-walled needle roller bearings are made of stamped steel plates.

Choose the right needle roller bearing

Needle roller bearing is a high-precision, high-load bearing, consisting of an inner ring, an outer ring, and needle rollers. Because of its advantages such as high precision, high load, and low friction, it is widely used in machine tools, heavy machinery, automobiles, motorcycles and other industries.

Needle roller bearing size chart

The following is a table of commonly used needle roller bearing models and their detailed parameter specifications for user reference.

NA4900 series

Inner diameter range: 10mm – 150mm

Outer diameter range: 22mm – 190mm

Width range: 13mm – 40mm

Basic load dynamic rating: 8600N – 135000N

Basic load static rating: 10000N – 166000N

Scope of application: Mostly used in motorcycles, bicycles and other fields.

NKI series

Inner diameter range: 5mm – 150mm

Outer diameter range: 15mm – 215mm

Width range: 12mm – 70mm

Basic load dynamic rating: 14700N – 390000N

Basic load static rating: 22500N – 670000N

Scope of application: Mostly used in home appliances, power tools, automobiles, motorcycles and other fields.

RNA series

Inner diameter range: 14mm – 360mm

Outer diameter range: 22mm – 440mm

Width range: 12mm – 80mm

Basic load dynamic rating: 16800N – 800000N

Basic load static rating: 22400N – 1330000N

Scope of application: Mostly used in heavy machinery, metallurgy, mining, rail transit and other fields.

HK series

Inner diameter range: 3mm – 60mm

Outer diameter range: 6.5mm – 68mm

Width range: 6mm – 25mm

Basic load dynamic rating: 2600N – 25600N

Basic load static rating: 2750N – 31500N

Application: Mostly used in home appliances, power tools, automobiles and other fields.

These are commonly used needle roller bearing models and their detailed parameter specifications. Since there are many types and specifications of needle roller bearings, appropriate products need to be selected according to the needs of different fields.

Factors to consider when choosing needle roller bearings

1. Select appropriate needle roller bearings according to the needs of different industries. For example, the machine tool field requires high-speed, high-precision, and low-noise products; the automotive field requires products with strong load-bearing capacity and good durability.

2. When selecting, you need to comprehensively consider the inner diameter, outer diameter, width and other parameters according to the needle roller bearing parameter table.

3. When installing, please refer to the product installation instructions and choose the correct installation method and tools to prevent damage during the installation process.

4. Needle roller bearings must be kept clean and dry during use to prevent corrosion, wear and other problems.

5. Regularly inspect, maintain and repair needle roller bearings to ensure their normal operation.