Bearing Manufacturer & Supplier

Specialize in ball bearings, roller bearings, thrust bearings, thin section bearings etc.

The Ultimate Guide to Robot Bearings

Robot bearings are an integral mechanical component in robot joints, their role is to minimize friction between moving parts and provide support for rotational or linear motion. Which robot bearing is selected depends on the specific operating requirements of the robot joint. For example, ball bearings are a popular option due to their low friction and high rotational speed capabilities, while roller bearings are preferred for applications requiring higher loads.

Table of Contents

ToggleWhat are robot bearings?

As robotics technology continues to advance, high-precision bearing assemblies are important than ever to accuracy and overall performance. Bearings play a vital role in the smooth, precise movement of robot joints. Without bearings, the robot cannot perform any longitudinal or lateral movement or rotation. Robot bearings are responsible for moving the arm in a precise manner. Bearings are usually made of chromium steel, stainless steel, ceramic or plastic. Thin-section bearings, angular contact bearings, crossed roller bearings and thrust bearings are all suitable for robots. Among them, thin-section bearings are very popular.

Types of robot bearings

Bearing selection significantly affects the efficiency, reliability and longevity of a robotic system. Bearings are commonly used on classic industrial robots for welding, painting and handling heavy parts, and on lightweight robots for assembly of light loads, maximizing payload and reducing inertia for improved responsiveness. Thin-wall bearings are often designed into robotic arm joints due to their lightweight, space-saving construction, and high-speed capabilities. Roller bearings are often the first choice for heavy load requirements. Slewing bearings are a common choice for main rotation and related lifting equipment. Hybrid bearings (ceramic balls with stainless steel rings) and fully ceramic bearings are alternatives for operation in harsh environments. Depending on the operating environment, load and speed can affect bearing performance. For example, 440C stainless steel alloy can be used in harsh or corrosive environments as well as in medical, food or chemical processing applications.

Thin section bearings

Thin section bearings provide higher speeds, greater efficiency and higher levels of flexibility. Bearing weight is reduced by a small difference in size between the inner and outer rings. Even if the bore diameter increases, the various series of thin-wall bearings still maintain the same cross-sectional dimensions. This type of design allows for a hollow shaft design where other components such as air, electrical or hydraulic lines can be used as passages. Other designs such as four-point contact thin-wall bearings can replace a pair of bearings for a compact design and stable performance.

Kaydon Reali-Slim® bearings are the premier choice for robot bearings. As robot design continues to evolve, many robot design engineers are specifying Kaydon bearings. Kaydon Robot Bearings provide compact, lightweight bearings to increase payload and minimize power requirements. While thin-section configurations have advantages, the increased flexibility makes the bearings susceptible to dimensional changes that can affect lubricant film formation. Material selection and attention to manufacturing are critical to bearing production. If the bearing is not perfect, small errors can cause the bearing to struggle to rotate smoothly, thereby increasing friction, wear and vibration. Thin section bearings can be designed as open, shielded or sealed and constructed of SAE 52100 chromium steel or grade 440 stainless steel. They are designed to carry some radial loads as well as moderate thrust loads in both directions. Some smaller thin-section bearings are also available with fiberglass-reinforced nylon high-speed synthetic cages.

Aubearing is another world-class bearing manufacturer that offers a full range of thin-section bearing types for demanding robotic applications and can manufacture thin-section bearings of Kaydon’s size and quality. Today’s improved robot designs rely on compact designs, light weight and small cross-section bearings. Thin-wall bearings are the best solution for robot design. Thin-section bearings are composed of seven open series and five sealed series. There are three types of open series: radial contact type C, angular contact type A and four-point contact type X. The thin-walled 6700 ,6800, 6900 series are available in various dust cover forms, flange forms, stainless steel forms, wide width forms, etc., with complete varieties.

RealiSlim Open Bearings

Part Number | Seal Type | Bore Dia | Outer Dia | Width | Ring Material | Ball Material | Dynamic Radial Load | Weight |

Open | 2″ | 2.5″ | 0.25″ | 52100 Chrome Steel | 52100 Chrome Steel | 450 lbs | 0.1 lbs | |

Open | 2″ | 2.5″ | 0.25″ | 52100 Chrome Steel | 52100 Chrome Steel | 393 lbs | 0.1 lbs | |

Open | 2″ | 2.5″ | 0.25″ | 52100 Chrome Steel | 52100 Chrome Steel | 514 lbs | 0.1 lbs | |

Open | 2.5″ | 3″ | 0.25″ | 52100 Chrome Steel | 52100 Chrome Steel | 459 lbs | 0.12 lbs | |

Open | 2.5″ | 3″ | 0.25″ | 52100 Chrome Steel | 52100 Chrome Steel | 442 lbs | 0.13 lbs | |

Open | 2.5″ | 3″ | 0.25″ | 52100 Chrome Steel | 52100 Chrome Steel | 583 lbs | 0.13 lbs | |

Open | 2.75″ | 3.25″ | 0.25″ | 52100 Chrome Steel | 52100 Chrome Steel | 614 lbs | 0.14 lbs | |

Open | 3″ | 3.5″ | 0.25″ | 52100 Chrome Steel | 52100 Chrome Steel | 507 lbs | 0.14 lbs | |

Open | 3″ | 3.5″ | 0.25″ | 52100 Chrome Steel | 52100 Chrome Steel | 487 lbs | 0.15 lbs | |

Open | 3″ | 3.5″ | 0.25″ | 52100 Chrome Steel | 52100 Chrome Steel | 643 lbs | 0.15 lbs | |

Open | 3.5″ | 4″ | 0.25″ | 52100 Chrome Steel | 52100 Chrome Steel | 552 lbs | 0.17 lbs | |

Open | 3.5″ | 4″ | 0.25″ | 52100 Chrome Steel | 52100 Chrome Steel | 530 lbs | 0.18 lbs | |

Open | 3.5″ | 4″ | 0.25″ | 52100 Chrome Steel | 52100 Chrome Steel | 701 lbs | 0.18 lbs | |

Open | 4″ | 4.5″ | 0.25″ | 52100 Chrome Steel | 52100 Chrome Steel | 595 lbs | 0.19 lbs | |

Open | 4″ | 4.5″ | 0.25″ | 52100 Chrome Steel | 52100 Chrome Steel | 756 lbs | 1205.0lbs | |

Open | 4″ | 4.5″ | 0.25″ | 52100 Chrome Steel | 52100 Chrome Steel | 756 lbs | 0.19 lbs | |

Open | 4.25″ | 4.75″ | 0.25″ | 52100 Chrome Steel | 52100 Chrome Steel | 616 lbs | 0.2 lbs | |

Open | 4.25″ | 4.75″ | 0.25″ | 52100 Chrome Steel | 52100 Chrome Steel | 591 lbs | 0.2 lbs | |

Open | 4.25″ | 4.75″ | 0.25″ | 52100 Chrome Steel | 52100 Chrome Steel | 783 lbs | 0.2 lbs | |

Open | 4.5″ | 5″ | 0.25″ | 52100 Chrome Steel | 52100 Chrome Steel | 637 lbs | 0.21 lbs | |

Open | 4.5″ | 5″ | 0.25″ | 52100 Chrome Steel | 52100 Chrome Steel | 610 lbs | 0.22 lbs | |

Open | 4.5″ | 5″ | 0.25″ | 52100 Chrome Steel | 52100 Chrome Steel | 809 lbs | 0.22 lbs | |

Open | 4.75″ | 5.25″ | 0.25″ | 52100 Chrome Steel | 52100 Chrome Steel | 657 lbs | 0.22 lbs | |

Open | 4.75″ | 5.25″ | 0.25″ | 52100 Chrome Steel | 52100 Chrome Steel | 629 lbs | 0.23 lbs | |

Open | 4.75″ | 5.25″ | 0.25″ | 52100 Chrome Steel | 52100 Chrome Steel | 834 lbs | 0.23 lbs | |

Open | 5″ | 5.5″ | 0.25″ | 52100 Chrome Steel | 52100 Chrome Steel | 676 lbs | 0.23 lbs | |

Open | 5″ | 5.5″ | 0.25″ | 52100 Chrome Steel | 52100 Chrome Steel | 648 lbs | 0.24 lbs | |

Open | 5″ | 5.5″ | 0.25″ | 52100 Chrome Steel | 52100 Chrome Steel | 859 lbs | 0.24 lbs | |

Open | 5.5″ | 6″ | 0.25″ | 52100 Chrome Steel | 52100 Chrome Steel | 715 lbs | 0.25 lbs | |

Open | 5.5″ | 6″ | 0.25″ | 52100 Chrome Steel | 52100 Chrome Steel | 685 lbs | 0.25 lbs | |

Open | 5.5″ | 6″ | 0.25″ | 52100 Chrome Steel | 52100 Chrome Steel | 908 lbs | 0.25 lbs | |

Open | 6″ | 6.5″ | 0.25″ | 52100 Chrome Steel | 52100 Chrome Steel | 752 lbs | 0.28 lbs | |

Open | 6″ | 6.5″ | 0.25″ | 52100 Chrome Steel | 52100 Chrome Steel | 720 lbs | 0.28 lbs | |

Open | 6″ | 6.5″ | 0.25″ | 52100 Chrome Steel | 52100 Chrome Steel | 955 lbs | 0.28 lbs | |

Open | 6.5″ | 7″ | 0.25″ | 52100 Chrome Steel | 52100 Chrome Steel | 788 lbs | 0.3 lbs | |

Open | 6.5″ | 7″ | 0.25″ | 52100 Chrome Steel | 52100 Chrome Steel | 754 lbs | 0.3 lbs | |

Open | 6.5″ | 7″ | 0.25″ | 52100 Chrome Steel | 52100 Chrome Steel | 1001 lbs | 0.3 lbs | |

Open | 7″ | 7.5″ | 0.25″ | 52100 Chrome Steel | 52100 Chrome Steel | 823 lbs | 0.32 lbs | |

Open | 7″ | 7.5″ | 0.25″ | 52100 Chrome Steel | 52100 Chrome Steel | 787 lbs | 0.31 lbs | |

Open | 7″ | 7.5″ | 0.25″ | 52100 Chrome Steel | 52100 Chrome Steel | 1046 lbs | 0.31 lbs | |

Open | 7.5″ | 8″ | 0.25″ | 52100 Chrome Steel | 52100 Chrome Steel | 857 lbs | 0.34 lbs | |

Open | 7.5″ | 8″ | 0.25″ | 52100 Chrome Steel | 52100 Chrome Steel | 820 lbs | 0.34 lbs | |

Open | 7.5″ | 8″ | 0.25″ | 52100 Chrome Steel | 52100 Chrome Steel | 1089 lbs | 0.34 lbs | |

Open | 8″ | 8.5″ | 0.25″ | 52100 Chrome Steel | 52100 Chrome Steel | 890 lbs | 0.36 lbs | |

Open | 8″ | 8.5″ | 0.25″ | 52100 Chrome Steel | 52100 Chrome Steel | 851 lbs | 0.38 lbs | |

Open | 8″ | 8.5″ | 0.25″ | 52100 Chrome Steel | 52100 Chrome Steel | 1131 lbs | 0.38 lbs | |

Open | 9″ | 9.5″ | 0.25″ | 52100 Chrome Steel | 52100 Chrome Steel | 954 lbs | 0.41 lbs | |

Open | 9″ | 9.5″ | 0.25″ | 52100 Chrome Steel | 52100 Chrome Steel | 912 lbs | 0.44 lbs | |

Open | 9″ | 9.5″ | 0.25″ | 52100 Chrome Steel | 52100 Chrome Steel | 1212 lbs | 0.44 lbs | |

Open | 10″ | 10.5″ | 0.25″ | 52100 Chrome Steel | 52100 Chrome Steel | 1014 lbs | 0.45 lbs | |

Open | 10″ | 10.5″ | 0.25″ | 52100 Chrome Steel | 52100 Chrome Steel | 969 lbs | 0.5 lbs | |

Open | 10″ | 10.5″ | 0.25″ | 52100 Chrome Steel | 52100 Chrome Steel | 1289 lbs | 0.5 lbs | |

Open | 11″ | 11.5″ | 0.25″ | 52100 Chrome Steel | 52100 Chrome Steel | 1072 lbs | 0.5 lbs | |

Open | 11″ | 11.5″ | 0.25″ | 52100 Chrome Steel | 52100 Chrome Steel | 1025 lbs | 0.52 lbs | |

Open | 11″ | 11.5″ | 0.25″ | 52100 Chrome Steel | 52100 Chrome Steel | 1362 lbs | 0.52 lbs | |

Open | 12″ | 12.5″ | 0.25″ | 52100 Chrome Steel | 52100 Chrome Steel | 1128 lbs | 0.54 lbs | |

Open | 12″ | 12.5″ | 0.25″ | 52100 Chrome Steel | 52100 Chrome Steel | 1078 lbs | 0.56 lbs | |

Open | 12″ | 12.5″ | 0.25″ | 52100 Chrome Steel | 52100 Chrome Steel | 1433 lbs | 0.56 lbs | |

Open | 1″ | 1.375″ | 0.1875″ | 52100 Chrome Steel | 52100 Chrome Steel | 194 lbs | 0.025 lbs | |

Open | 1″ | 1.375″ | 0.1875″ | 52100 Chrome Steel | 52100 Chrome Steel | 188 lbs | 0.026 lbs | |

Open | 1″ | 1.375″ | 0.1875″ | 52100 Chrome Steel | 52100 Chrome Steel | 247 lbs | 0.025 lbs | |

Open | 1.5″ | 1.875″ | 0.1875″ | 52100 Chrome Steel | 52100 Chrome Steel | 238 lbs | 0.038 lbs | |

Open | 1.5″ | 1.875″ | 0.1875″ | 52100 Chrome Steel | 52100 Chrome Steel | 225 lbs | 0.039 lbs | |

Open | 1.5″ | 1.875″ | 0.1875″ | 52100 Chrome Steel | 52100 Chrome Steel | 296 lbs | 0.039 lbs | |

Open | 1.75″ | 2.125″ | 0.1875″ | 52100 Chrome Steel | 52100 Chrome Steel | 251 lbs | 0.045 lbs | |

Open | 1.75″ | 2.125″ | 0.1875″ | 52100 Chrome Steel | 52100 Chrome Steel | 242 lbs | 0.045 lbs | |

Open | 1.75″ | 2.125″ | 0.1875″ | 52100 Chrome Steel | 52100 Chrome Steel | 319 lbs | 0.045 lbs | |

Open | 2″ | 2.625″ | 0.3125″ | 52100 Chrome Steel | 52100 Chrome Steel | 601 lbs | 0.15 lbs | |

Open | 2″ | 2.625″ | 0.3125″ | 52100 Chrome Steel | 52100 Chrome Steel | 577 lbs | 0.16 lbs | |

Open | 2″ | 2.625″ | 0.3125″ | 52100 Chrome Steel | 52100 Chrome Steel | 758 lbs | 0.16 lbs | |

Open | 2.5″ | 3.125″ | 0.3125″ | 52100 Chrome Steel | 52100 Chrome Steel | 675 lbs | 0.19 lbs | |

Open | 2.5″ | 3.125″ | 0.3125″ | 52100 Chrome Steel | 52100 Chrome Steel | 644 lbs | 0.2 lbs | |

Open | 2.5″ | 3.125″ | 0.3125″ | 52100 Chrome Steel | 52100 Chrome Steel | 848 lbs | 0.19 lbs | |

Open | 3″ | 3.625″ | 0.3125″ | 52100 Chrome Steel | 52100 Chrome Steel | 734 lbs | 0.22 lbs | |

Open | 3″ | 3.625″ | 0.3125″ | 52100 Chrome Steel | 52100 Chrome Steel | 707 lbs | 0.24 lbs | |

Open | 3″ | 3.625″ | 0.3125″ | 52100 Chrome Steel | 52100 Chrome Steel | 933 lbs | 0.24 lbs | |

Open | 3.5″ | 4.125″ | 0.3125″ | 52100 Chrome Steel | 52100 Chrome Steel | 801 lbs | 0.27 lbs | |

Open | 3.5″ | 4.125″ | 0.3125″ | 52100 Chrome Steel | 52100 Chrome Steel | 767 lbs | 0.27 lbs | |

Open | 3.5″ | 4.125″ | 0.3125″ | 52100 Chrome Steel | 52100 Chrome Steel | 1014 lbs | 0.27 lbs | |

Open | 4″ | 4.625″ | 0.3125″ | 52100 Chrome Steel | 52100 Chrome Steel | 865 lbs | 0.3 lbs | |

Open | 4″ | 4.625″ | 0.3125″ | 52100 Chrome Steel | 52100 Chrome Steel | 825 lbs | 0.3 lbs | |

Open | 4″ | 4.625″ | 0.3125″ | 52100 Chrome Steel | 52100 Chrome Steel | 1091 lbs | 0.3 lbs | |

Open | 4.25″ | 4.875″ | 0.3125″ | 52100 Chrome Steel | 52100 Chrome Steel | 891 lbs | 0.31 lbs | |

Open | 4.25″ | 4.875″ | 0.3125″ | 52100 Chrome Steel | 52100 Chrome Steel | 846 lbs | 0.31 lbs | |

Open | 4.25″ | 4.875″ | 0.3125″ | 52100 Chrome Steel | 52100 Chrome Steel | 1120 lbs | 0.31 lbs | |

Open | 4.5″ | 5.125″ | 0.3125″ | 52100 Chrome Steel | 52100 Chrome Steel | 917 lbs | 0.34 lbs | |

Open | 4.5″ | 5.125″ | 0.3125″ | 52100 Chrome Steel | 52100 Chrome Steel | 880 lbs | 0.33 lbs | |

Open | 4.5″ | 5.125″ | 0.3125″ | 52100 Chrome Steel | 52100 Chrome Steel | 1165 lbs | 0.33 lbs | |

Open | 4.75″ | 5.375″ | 0.3125″ | 52100 Chrome Steel | 52100 Chrome Steel | 951 lbs | 0.35 lbs | |

Open | 4.75″ | 5.375″ | 0.3125″ | 52100 Chrome Steel | 52100 Chrome Steel | 901 lbs | 0.34 lbs | |

Open | 4.75″ | 5.375″ | 0.3125″ | 52100 Chrome Steel | 52100 Chrome Steel | 1193 lbs | 0.34 lbs | |

Open | 5″ | 5.625″ | 0.3125″ | 52100 Chrome Steel | 52100 Chrome Steel | 976 lbs | 0.37 lbs | |

Open | 5″ | 5.625″ | 0.3125″ | 52100 Chrome Steel | 52100 Chrome Steel | 933 lbs | 0.38 lbs | |

Open | 5″ | 5.625″ | 0.3125″ | 52100 Chrome Steel | 52100 Chrome Steel | 1236 lbs | 0.38 lbs | |

Open | 5.5″ | 6.125″ | 0.3125″ | 52100 Chrome Steel | 52100 Chrome Steel | 1033 lbs | 0.4 lbs | |

Open | 5.5″ | 6.125″ | 0.3125″ | 52100 Chrome Steel | 52100 Chrome Steel | 984 lbs | 0.41 lbs | |

Open | 5.5″ | 6.125″ | 0.3125″ | 52100 Chrome Steel | 52100 Chrome Steel | 1304 lbs | 0.41 lbs | |

Open | 6″ | 6.625″ | 0.3125″ | 52100 Chrome Steel | 52100 Chrome Steel | 1088 lbs | 0.44 lbs | |

Open | 6″ | 6.625″ | 0.3125″ | 52100 Chrome Steel | 52100 Chrome Steel | 1034 lbs | 0.44 lbs | |

Open | 6″ | 6.625″ | 0.3125″ | 52100 Chrome Steel | 52100 Chrome Steel | 1371 lbs | 0.44 lbs |

RealiSlim Sealed Bearings

| Part Number | Seal Type | Bore Dia | Outer Dia | Width | Ring Material | Dynamic Radial Load | Static Radial Load | Weight |

| JA020CP0 | Sealed | 2″ | 2.5″ | 0.25″ | 52100 Chrome Steel | 393 lbs | 680 lbs | 0.1 lbs |

| JA020XP0 | Sealed | 2″ | 2.5″ | 0.25″ | 52100 Chrome Steel | 514 lbs | 680 lbs | 0.1 lbs |

| JA025CP0 | Sealed | 2.5″ | 3″ | 0.25″ | 52100 Chrome Steel | 442 lbs | 830 lbs | 0.12 lbs |

| JA025XP0 | Sealed | 2.5″ | 3″ | 0.25″ | 52100 Chrome Steel | 583 lbs | 830 lbs | 0.12 lbs |

| JA030CP0 | Sealed | 3″ | 3.5″ | 0.25″ | 52100 Chrome Steel | 487 lbs | 990 lbs | 0.14 lbs |

| JA030XP0 | Sealed | 3″ | 3.5″ | 0.25″ | 52100 Chrome Steel | 643 lbs | 990 lbs | 0.14 lbs |

| JA035CP0 | Sealed | 3.5″ | 4″ | 0.25″ | 52100 Chrome Steel | 530 lbs | 1140 lbs | 0.17 lbs |

| JA035XP0 | Sealed | 3.5″ | 4″ | 0.25″ | 52100 Chrome Steel | 701 lbs | 1140 lbs | 0.17 lbs |

| JA040CP0 | Sealed | 4″ | 4.5″ | 0.25″ | 52100 Chrome Steel | 571 lbs | 1290 lbs | 0.19 lbs |

| JA040XP0 | Sealed | 4″ | 4.5″ | 0.25″ | 52100 Chrome Steel | 756 lbs | 1290 lbs | 0.19 lbs |

| JA042CP0 | Sealed | 4.25″ | 4.75″ | 0.25″ | 52100 Chrome Steel | 591 lbs | 1370 lbs | 0.2 lbs |

| JA042XP0 | Sealed | 4.25″ | 4.75″ | 0.25″ | 52100 Chrome Steel | 783 lbs | 1370 lbs | 0.2 lbs |

| JA045CP0 | Sealed | 4.5″ | 5″ | 0.25″ | 52100 Chrome Steel | 610 lbs | 1440 lbs | 0.21 lbs |

| JA045XP0 | Sealed | 4.5″ | 5″ | 0.25″ | 52100 Chrome Steel | 809 lbs | 1440 lbs | 0.21 lbs |

| JA047CP0 | Sealed | 4.75″ | 5.25″ | 0.25″ | 52100 Chrome Steel | 629 lbs | 1520 lbs | 0.22 lbs |

| JA047XP0 | Sealed | 4.75″ | 5.25″ | 0.25″ | 52100 Chrome Steel | 834 lbs | 1520 lbs | 0.22 lbs |

| JA050CP0 | Sealed | 5″ | 5.5″ | 0.25″ | 52100 Chrome Steel | 648 lbs | 1590 lbs | 0.23 lbs |

| JA050XP0 | Sealed | 5″ | 5.5″ | 0.25″ | 52100 Chrome Steel | 859 lbs | 1590 lbs | 0.23 lbs |

| JA055CP0 | Sealed | 5.5″ | 6″ | 0.25″ | 52100 Chrome Steel | 685 lbs | 1750 lbs | 0.25 lbs |

| JA055XP0 | Sealed | 5.5″ | 6″ | 0.25″ | 52100 Chrome Steel | 908 lbs | 1750 lbs | 0.25 lbs |

| JA060CP0 | Sealed | 6″ | 6.5″ | 0.25″ | 52100 Chrome Steel | 720 lbs | 1900 lbs | 0.28 lbs |

| JA060XP0 | Sealed | 6″ | 6.5″ | 0.25″ | 52100 Chrome Steel | 955 lbs | 1900 lbs | 0.28 lbs |

| JA065CP0 | Sealed | 6.5″ | 7″ | 0.25″ | 52100 Chrome Steel | 754 lbs | 2050 lbs | 0.3 lbs |

| JA065XP0 | Sealed | 6.5″ | 7″ | 0.25″ | 52100 Chrome Steel | 1001 lbs | 2050 lbs | 0.3 lbs |

| JA070CP0 | Sealed | 7″ | 7.5″ | 0.25″ | 52100 Chrome Steel | 787 lbs | 2200 lbs | 0.31 lbs |

| JA070XP0 | Sealed | 7″ | 7.5″ | 0.25″ | 52100 Chrome Steel | 1046 lbs | 2200 lbs | 0.31 lbs |

| JA075CP0 | Sealed | 7.5″ | 8″ | 0.25″ | 52100 Chrome Steel | 820 lbs | 2350 lbs | 0.34 lbs |

| JA075XP0 | Sealed | 7.5″ | 8″ | 0.25″ | 52100 Chrome Steel | 1089 lbs | 2350 lbs | 0.34 lbs |

| JB020CP0 | Sealed | 2″ | 2.625″ | 0.3125″ | 52100 Chrome Steel | 577 lbs | 930 lbs | 0.15 lbs |

| JB020XP0 | Sealed | 2″ | 2.625″ | 0.3125″ | 52100 Chrome Steel | 758 lbs | 930 lbs | 0.15 lbs |

| JB025CP0 | Sealed | 2.5″ | 3.125″ | 0.3125″ | 52100 Chrome Steel | 644 lbs | 1140 lbs | 0.19 lbs |

| JB025XP0 | Sealed | 2.5″ | 3.125″ | 0.3125″ | 52100 Chrome Steel | 848 lbs | 1140 lbs | 0.19 lbs |

| JB030CP0 | Sealed | 3″ | 3.625″ | 0.3125″ | 52100 Chrome Steel | 707 lbs | 1340 lbs | 0.22 lbs |

| JB030XP0 | Sealed | 3″ | 3.625″ | 0.3125″ | 52100 Chrome Steel | 933 lbs | 1340 lbs | 0.22 lbs |

| JB035CP0 | Sealed | 3.5″ | 4.125″ | 0.3125″ | 52100 Chrome Steel | 767 lbs | 1540 lbs | 0.27 lbs |

| JB035XP0 | Sealed | 3.5″ | 4.125″ | 0.3125″ | 52100 Chrome Steel | 1014 lbs | 1540 lbs | 0.27 lbs |

| JB040CP0 | Sealed | 4″ | 4.625″ | 0.3125″ | 52100 Chrome Steel | 825 lbs | 1750 lbs | 0.3 lbs |

| JB040XP0 | Sealed | 4″ | 4.625″ | 0.3125″ | 52100 Chrome Steel | 1091 lbs | 1750 lbs | 0.3 lbs |

| JB042CP0 | Sealed | 4.25″ | 4.875″ | 0.3125″ | 52100 Chrome Steel | 846 lbs | 1830 lbs | 0.31 lbs |

| JB042XP0 | Sealed | 4.25″ | 4.875″ | 0.3125″ | 52100 Chrome Steel | 1120 lbs | 1830 lbs | 0.31 lbs |

| JB045CP0 | Sealed | 4.5″ | 5.125″ | 0.3125″ | 52100 Chrome Steel | 880 lbs | 1950 lbs | 0.34 lbs |

| JB045XP0 | Sealed | 4.5″ | 5.125″ | 0.3125″ | 52100 Chrome Steel | 1165 lbs | 1950 lbs | 0.34 lbs |

| JB047CP0 | Sealed | 4.75″ | 5.375″ | 0.3125″ | 52100 Chrome Steel | 901 lbs | 2030 lbs | 0.35 lbs |

| JB047XP0 | Sealed | 4.75″ | 5.375″ | 0.3125″ | 52100 Chrome Steel | 1193 lbs | 2030 lbs | 0.35 lbs |

| JB050CP0 | Sealed | 5″ | 5.625″ | 0.3125″ | 52100 Chrome Steel | 933 lbs | 2150 lbs | 0.37 lbs |

| JB050XP0 | Sealed | 5″ | 5.625″ | 0.3125″ | 52100 Chrome Steel | 1236 lbs | 2150 lbs | 0.37 lbs |

| JB055CP0 | Sealed | 5.5″ | 6.125″ | 0.3125″ | 52100 Chrome Steel | 984 lbs | 2360 lbs | 0.4 lbs |

| JB055XP0 | Sealed | 5.5″ | 6.125″ | 0.3125″ | 52100 Chrome Steel | 1304 lbs | 2360 lbs | 0.4 lbs |

| JB060CP0 | Sealed | 6″ | 6.625″ | 0.3125″ | 52100 Chrome Steel | 1034 lbs | 2560 lbs | 0.44 lbs |

| JB060XP0 | Sealed | 6″ | 6.625″ | 0.3125″ | 52100 Chrome Steel | 1371 lbs | 2560 lbs | 0.44 lbs |

| JB065CP0 | Sealed | 6.5″ | 7.125″ | 0.3125″ | 52100 Chrome Steel | 1082 lbs | 2760 lbs | 0.47 lbs |

| JB065XP0 | Sealed | 6.5″ | 7.125″ | 0.3125″ | 52100 Chrome Steel | 1435 lbs | 2760 lbs | 0.47 lbs |

| JG070CP0 | Sealed | 7″ | 9″ | 1″ | 52100 Chrome Steel | 7764 lbs | 13130 lbs | 5.8 lbs |

| JG070XP0 | Sealed | 7″ | 9″ | 1″ | 52100 Chrome Steel | 10208 lbs | 13130 lbs | 5.8 lbs |

| JG075CP0 | Sealed | 7.5″ | 9.5″ | 1″ | 52100 Chrome Steel | 7911 lbs | 13680 lbs | 6.1 lbs |

| JG075XP0 | Sealed | 7.5″ | 9.5″ | 1″ | 52100 Chrome Steel | 10410 lbs | 13680 lbs | 6.1 lbs |

| JG080CP0 | Sealed | 8″ | 10″ | 1″ | 52100 Chrome Steel | 8265 lbs | 14770 lbs | 6.5 lbs |

| JG080XP0 | Sealed | 8″ | 10″ | 1″ | 52100 Chrome Steel | 10882 lbs | 14770 lbs | 6.5 lbs |

| JG090CP0 | Sealed | 9″ | 11″ | 1″ | 52100 Chrome Steel | 8743 lbs | 16420 lbs | 7.2 lbs |

| JG090XP0 | Sealed | 9″ | 11″ | 1″ | 52100 Chrome Steel | 11526 lbs | 16420 lbs | 7.2 lbs |

| JG100CP0 | Sealed | 10″ | 12″ | 1″ | 52100 Chrome Steel | 9204 lbs | 18060 lbs | 7.9 lbs |

| JG100XP0 | Sealed | 10″ | 12″ | 1″ | 52100 Chrome Steel | 12147 lbs | 18060 lbs | 7.9 lbs |

| JG110CP0 | Sealed | 11″ | 13″ | 1″ | 52100 Chrome Steel | 9648 lbs | 19700 lbs | 8.6 lbs |

| JG110XP0 | Sealed | 11″ | 13″ | 1″ | 52100 Chrome Steel | 12739 lbs | 19700 lbs | 8.6 lbs |

| JG120CP0 | Sealed | 12″ | 14″ | 1″ | 52100 Chrome Steel | 10074 lbs | 21340 lbs | 9.3 lbs |

| JG120XP0 | Sealed | 12″ | 14″ | 1″ | 52100 Chrome Steel | 13315 lbs | 21340 lbs | 9.3 lbs |

| JG140CP0 | Sealed | 14″ | 16″ | 1″ | 52100 Chrome Steel | 10886 lbs | 24620 lbs | 10.8 lbs |

| JG140XP0 | Sealed | 14″ | 16″ | 1″ | 52100 Chrome Steel | 14404 lbs | 24620 lbs | 10.8 lbs |

| JG160CP0 | Sealed | 16″ | 18″ | 1″ | 52100 Chrome Steel | 11648 lbs | 27910 lbs | 12.3 lbs |

| JG160XP0 | Sealed | 16″ | 18″ | 1″ | 52100 Chrome Steel | 15425 lbs | 27910 lbs | 12.3 lbs |

| JG180CP0 | Sealed | 18″ | 20″ | 1″ | 52100 Chrome Steel | 12367 lbs | 31190 lbs | 13.7 lbs |

| JG180XP0 | Sealed | 18″ | 20″ | 1″ | 52100 Chrome Steel | 16386 lbs | 31190 lbs | 13.7 lbs |

| JG200CP0 | Sealed | 20″ | 22″ | 1″ | 52100 Chrome Steel | 13044 lbs | 34470 lbs | 15.8 lbs |

| JG200XP0 | Sealed | 20″ | 22″ | 1″ | 52100 Chrome Steel | 17293 lbs | 34470 lbs | 15.8 lbs |

| JG220CP0 | Sealed | 22″ | 24″ | 1″ | 52100 Chrome Steel | 13685 lbs | 37760 lbs | 16.8 lbs |

| JG220XP0 | Sealed | 22″ | 24″ | 1″ | 52100 Chrome Steel | 18152 lbs | 37750 lbs | 16.8 lbs |

| JG250CP0 | Sealed | 25″ | 27″ | 1″ | 52100 Chrome Steel | 14591 lbs | 42680 lbs | 19.5 lbs |

| JG250XP0 | Sealed | 25″ | 27″ | 1″ | 52100 Chrome Steel | 19360 lbs | 42680 lbs | 19.5 lbs |

| JG300CP0 | Sealed | 30″ | 32″ | 1″ | 52100 Chrome Steel | 15963 lbs | 50890 lbs | 23.3 lbs |

| JG300XP0 | Sealed | 30″ | 32″ | 1″ | 52100 Chrome Steel | 21200 lbs | 50890 lbs | 23.3 lbs |

| JG350CP0 | Sealed | 35″ | 37″ | 1″ | 52100 Chrome Steel | 17195 lbs | 59100 lbs | 27.1 lbs |

| JG350XP0 | Sealed | 35″ | 37″ | 1″ | 52100 Chrome Steel | 22845 lbs | 59100 lbs | 27.1 lbs |

| JG400CP0 | Sealed | 40″ | 42″ | 1″ | 52100 Chrome Steel | 18307 lbs | 67310 lbs | 30.8 lbs |

| JG400XP0 | Sealed | 40″ | 42″ | 1″ | 52100 Chrome Steel | 24332 lbs | 63310 lbs | 30.8 lbs |

| JHA10CL0 | Sealed | 1″ | 1.375″ | 0.25″ | 52100 Chrome Steel | 188 lbs | 290 lbs | 0.035 lbs |

| JHA10XL0 | Sealed | 1″ | 1.375″ | 0.25″ | 52100 Chrome Steel | 247 lbs | 290 lbs | 0.035 lbs |

| JHA15CL0 | Sealed | 1.5″ | 1.875″ | 0.25″ | 52100 Chrome Steel | 225 lbs | 400 lbs | 0.052 lbs |

| JHA15XL0 | Sealed | 1.5″ | 1.875″ | 0.25″ | 52100 Chrome Steel | 296 lbs | 400 lbs | 0.052 lbs |

| JHA17CL0 | Sealed | 1.75″ | 2.125″ | 0.25″ | 52100 Chrome Steel | 242 lbs | 460 lbs | 0.06 lbs |

| JHA17XL0 | Sealed | 1.75″ | 2.125″ | 0.25″ | 52100 Chrome Steel | 319 lbs | 460 lbs | 0.06 lbs |

| JU040CP0 | Sealed | 4″ | 4.75″ | 0.5″ | 52100 Chrome Steel | 1073 lbs | 2100 lbs | 0.55 lbs |

| JU040XP0 | Sealed | 4″ | 4.75″ | 0.5″ | 52100 Chrome Steel | 1417 lbs | 2100 lbs | 0.55 lbs |

| JU042CP0 | Sealed | 4.25″ | 5″ | 0.5″ | 52100 Chrome Steel | 1108 lbs | 2220 lbs | 0.58 lbs |

| JU042XP0 | Sealed | 4.25″ | 5″ | 0.5″ | 52100 Chrome Steel | 1464 lbs | 2220 lbs | 0.58 lbs |

| JU045CP0 | Sealed | 4.5″ | 5.25″ | 0.5″ | 52100 Chrome Steel | 1143 lbs | 2340 lbs | 0.61 lbs |

| JU045XP0 | Sealed | 4.5″ | 5.25″ | 0.5″ | 52100 Chrome Steel | 1510 lbs | 2340 lbs | 0.61 lbs |

| JU047CP0 | Sealed | 4.75″ | 5.5″ | 0.5″ | 52100 Chrome Steel | 1176 lbs | 2460 lbs | 0.65 lbs |

| JU047XP0 | Sealed | 4.75″ | 5.5″ | 0.5″ | 52100 Chrome Steel | 1556 lbs | 2460 lbs | 0.65 lbs |

| JU050CP0 | Sealed | 5″ | 5.75″ | 0.5″ | 52100 Chrome Steel | 1209 lbs | 2590 lbs | 0.68 lbs |

| JU050XP0 | Sealed | 5″ | 5.75″ | 0.5″ | 52100 Chrome Steel | 1600 lbs | 2590 lbs | 0.68 lbs |

UltraSlim Thin Section Bearings

| Part Number | Seal Type | Bore Dia | Outer Dia | Width | Ring Material | Dynamic Radial Load | Static Radial Load | Weight |

| S03503AS0 | Open | 35 mm | 41 mm | 2.5 mm | 440C Stainless Steel | 86 lbs | 86 lbs | 5.0 g |

| S03503CS0 | Open | 35 mm | 41 mm | 2.5 mm | 440C Stainless Steel | 94 lbs | 94 lbs | 5.0 g |

| S03503XS0 | Open | 35 mm | 41 mm | 2.5 mm | 440C Stainless Steel | 132 lbs | 160 lbs | 5.0 g |

| S06003AS0 | Open | 60 mm | 66 mm | 2.5 mm | 440C Stainless Steel | 124 lbs | 146 lbs | 9.0 g |

| S06003CS0 | Open | 60 mm | 66 mm | 2.5 mm | 440C Stainless Steel | 136 lbs | 160 lbs | 9.0 g |

| S06003XS0 | Open | 60 mm | 66 mm | 2.5 mm | 440C Stainless Steel | 190 lbs | 272 lbs | 9.0 g |

| S07003AS0 | Open | 70 mm | 76 mm | 2.5 mm | 440C Stainless Steel | 137 lbs | 170 lbs | 11.0 g |

| S07003CS0 | Open | 70 mm | 76 mm | 2.5 mm | 440C Stainless Steel | 150 lbs | 186 lbs | 11.0 g |

| S07003XS0 | Open | 70 mm | 76 mm | 2.5 mm | 440C Stainless Steel | 210 lbs | 316 lbs | 11.0 g |

| S07403AS0 | Open | 74 mm | 80 mm | 2.5 mm | 440C Stainless Steel | 142 lbs | 180 lbs | 11.0 g |

| S07403CS0 | Open | 74 mm | 80 mm | 2.5 mm | 440C Stainless Steel | 155 lbs | 197 lbs | 11.0 g |

| S07403XS0 | Open | 74 mm | 80 mm | 2.5 mm | 440C Stainless Steel | 217 lbs | 334 lbs | 11.0 g |

| S08003AS0 | Open | 80 mm | 86 mm | 2.5 mm | 440C Stainless Steel | 149 lbs | 194 lbs | 12.0 g |

| S08003CS0 | Open | 80 mm | 86 mm | 2.5 mm | 440C Stainless Steel | 163 lbs | 212 lbs | 12.0 g |

| S08003XS0 | Open | 80 mm | 86 mm | 2.5 mm | 440C Stainless Steel | 228 lbs | 361 lbs | 12.0 g |

| S09003AS0 | Open | 90 mm | 96 mm | 2.5 mm | 440C Stainless Steel | 161 lbs | 218 lbs | 13.0 g |

| S09003CS0 | Open | 90 mm | 96 mm | 2.5 mm | 440C Stainless Steel | 176 lbs | 239 lbs | 13.0 g |

| S09003XS0 | Open | 90 mm | 96 mm | 2.5 mm | 440C Stainless Steel | 246 lbs | 406 lbs | 13.0 g |

| S10003AS0 | Open | 100 mm | 106 mm | 2.5 mm | 440C Stainless Steel | 172 lbs | 242 lbs | 15.0 g |

| S10003CS0 | Open | 100 mm | 106 mm | 2.5 mm | 440C Stainless Steel | 189 lbs | 265 lbs | 15.0 g |

| S10003XS0 | Open | 100 mm | 106 mm | 2.5 mm | 440C Stainless Steel | 265 lbs | 450 lbs | 15.0 g |

| S11003AS0 | Open | 110 mm | 116 mm | 2.5 mm | 440C Stainless Steel | 183 lbs | 266 lbs | 16.0 g |

| S11003CS0 | Open | 110 mm | 116 mm | 2.5 mm | 440C Stainless Steel | 201 lbs | 291 lbs | 16.0 g |

| S11003XS0 | Open | 110 mm | 116 mm | 2.5 mm | 440C Stainless Steel | 281 lbs | 495 lbs | 16.0 g |

| S12003AS0 | Open | 120 mm | 126 mm | 2.5 mm | 440C Stainless Steel | 194 lbs | 290 lbs | 18.0 g |

| S12003CS0 | Open | 120 mm | 126 mm | 2.5 mm | 440C Stainless Steel | 212 lbs | 317 lbs | 18.0 g |

| S12003XS0 | Open | 120 mm | 126 mm | 2.5 mm | 440C Stainless Steel | 297 lbs | 540 lbs | 18.0 g |

| S13003AS0 | Open | 130 mm | 136 mm | 2.5 mm | 440C Stainless Steel | 205 lbs | 316 lbs | 19.0 g |

| S13003CS0 | Open | 130 mm | 136 mm | 2.5 mm | 440C Stainless Steel | 225 lbs | 346 lbs | 19.0 g |

| S13003XS0 | Open | 130 mm | 136 mm | 2.5 mm | 440C Stainless Steel | 315 lbs | 589 lbs | 19.0 g |

| S14003AS0 | Open | 140 mm | 146 mm | 2.5 mm | 440C Stainless Steel | 215 lbs | 340 lbs | 21.0 g |

| S14003CS0 | Open | 140 mm | 146 mm | 2.5 mm | 440C Stainless Steel | 236 lbs | 373 lbs | 21.0 g |

| S14003XS0 | Open | 140 mm | 146 mm | 2.5 mm | 440C Stainless Steel | 330 lbs | 633 lbs | 21.0 g |

| S15003AS0 | Open | 150 mm | 156 mm | 2.5 mm | 440C Stainless Steel | 225 lbs | 364 lbs | 22.0 g |

| S15003CS0 | Open | 150 mm | 156 mm | 2.5 mm | 440C Stainless Steel | 247 lbs | 399 lbs | 22.0 g |

| S15003XS0 | Open | 150 mm | 156 mm | 2.5 mm | 440C Stainless Steel | 346 lbs | 678 lbs | 22.0 g |

| S16003AS0 | Open | 160 mm | 166 mm | 2.5 mm | 440C Stainless Steel | 235 lbs | 388 lbs | 24.0 g |

| S16003CS0 | Open | 160 mm | 166 mm | 2.5 mm | 440C Stainless Steel | 257 lbs | 425 lbs | 24.0 g |

| S16003XS0 | Open | 160 mm | 166 mm | 2.5 mm | 440C Stainless Steel | 360 lbs | 723 lbs | 24.0 g |

| S17003AS0 | Open | 170 mm | 176 mm | 2.5 mm | 440C Stainless Steel | 244 lbs | 412 lbs | 25.0 g |

| S17003CS0 | Open | 170 mm | 176 mm | 2.5 mm | 440C Stainless Steel | 268 lbs | 451 lbs | 25.0 g |

| S17003XS0 | Open | 170 mm | 176 mm | 2.5 mm | 440C Stainless Steel | 375 lbs | 767 lbs | 25.0 g |

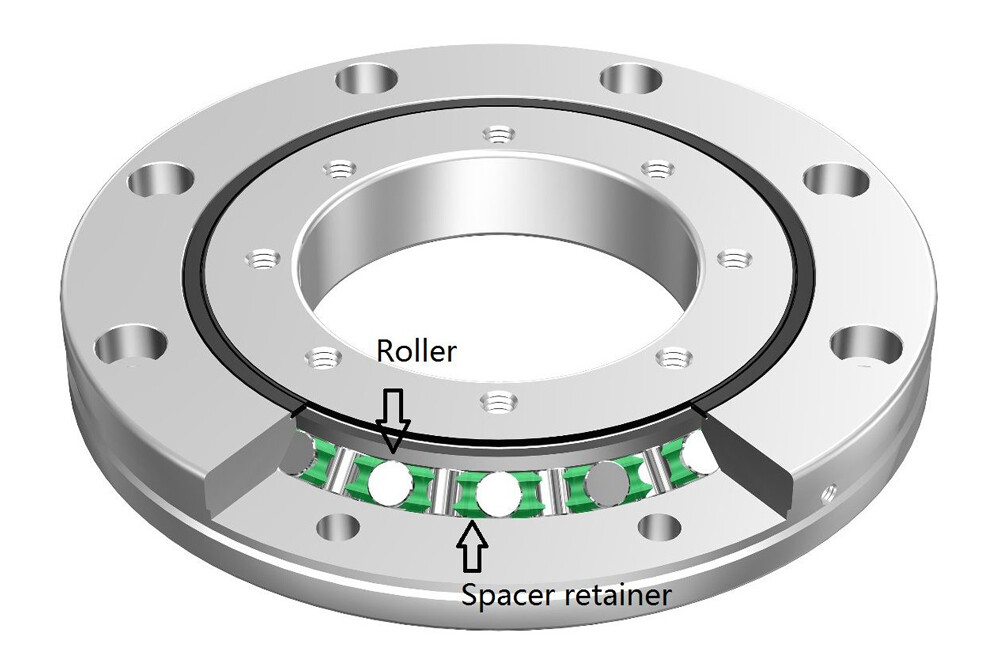

Crossed Roller Bearings

Crossed roller bearings are ideal for high rigidity spherical plain bearings. Crossed roller bearings are cylindrical rollers or tapered rollers arranged vertically with each other on a 90-degree V-shaped groove rolling surface through isolation blocks. Therefore, crossed roller bearings can bear radial load, axial load and moment load. Loads in multiple directions. This design prevents the rollers from tilting or the rollers rubbing against each other, effectively preventing the increase in rotational torque. In addition, there will be no contact or locking of one roller; at the same time, because the inner and outer rings are divided structures, the gap can be adjusted, and high-precision rotation can be obtained even if preload is applied. The size of the inner and outer rings has been miniaturized, and the ultra-thin form is close to the extreme small size and has high rigidity. Therefore, it is suitable for joints and rotating parts of industrial robots.

Angular contact bearings

Angular contact ball bearings can bear both radial and axial loads. Can work at higher speeds. The larger the contact angle, the higher the axial load capacity. The contact angle is the angle between the line connecting the contact points of the ball and the raceway in the radial plane and the vertical line of the bearing axis. High-precision and high-speed bearings usually have a contact angle of 15 degrees. Under the action of axial force, the contact angle will increase. Angular contact bearings have a compact cross-section and are ideally suited for use in robot joints. For robotic applications, they are mainly used in servo drives, robot joints, and output bearings in planetary gearboxes. Super precision angular contact ball bearings are suitable for high speed, high tolerance and rigid applications. When used with cages and ceramic materials, bearings provide enhanced resistance to distortion and temperature. Their contact angles range is 15° to 45°.

RV reducer bearings

RV reducer, also known as precision joint reducer, is widely used in industrial robots due to its small size, strong impact resistance, large torque, and high positioning accuracy. For RV reducers, the shape structure and precise positioning of the bearings are key factors for its compact structure, excellent rigidity, and precise transmission. RV reducer bearings include a variety of thin-walled bearing series and cylindrical roller cage assembly series.

Harmonic reducer

The harmonic reducer uses a wave generator to produce controllable elastic deformation of the flexspline, and uses the controllable elastic deformation of the flexible bearing to transmit motion and power. It is characterized by compact structure, high motion accuracy, large transmission ratio, and multi-purpose For robot joints with small and medium torque.

Thrust bearings

The thrust bearing is a special rotating bearing designed to withstand axial loads and ensure the effective transmission of axial loads on the robot. The structure of a thrust bearing usually includes two or thrust washers (also called thrust washers), and several rolling elements. These rolling elements can be integrated with an iron or copper cage. Thrust bearings can be divided into many types according to different designs and uses, including but not limited to thrust ball bearings, thrust cylindrical roller bearings, thrust needle roller bearings, thrust tapered roller bearings and thrust strip roller bearings.

Slewing ring

Slewing bearing is a new type of robot component. It consists of inner and outer rings, rolling elements and other parts, and has the ability to withstand comprehensive loads, including large axial and radial loads and overturning moments. The slewing bearing can maintain stable operation while performing relative rotational motion between two objects, so it is often known as the “joint of the machine”. Slewing bearings are strong and compact, taking up minimal space, while still providing considerable strength for applications where space savings or weight restrictions may be required. The design and structure of slewing bearings allow them to handle extreme moment loads and can withstand large axial and radial loads as well as overturning moments simultaneously.

Robot bearing materials

The material selection of robot bearings is affected by many factors, such as the temperature, humidity, load, and movement speed of the robot’s working environment. The material of special bearings for robot reducers is generally high-strength, corrosion-resistant, and high-temperature-resistant alloy steel, such as stainless steel, chromium steel, etc. These alloy steels have good hardenability and high temperature performance, and can meet the use requirements of robot reducers under harsh working conditions such as high load, high speed, and high temperature.

Chrome Steel Bearings — SAE 52100

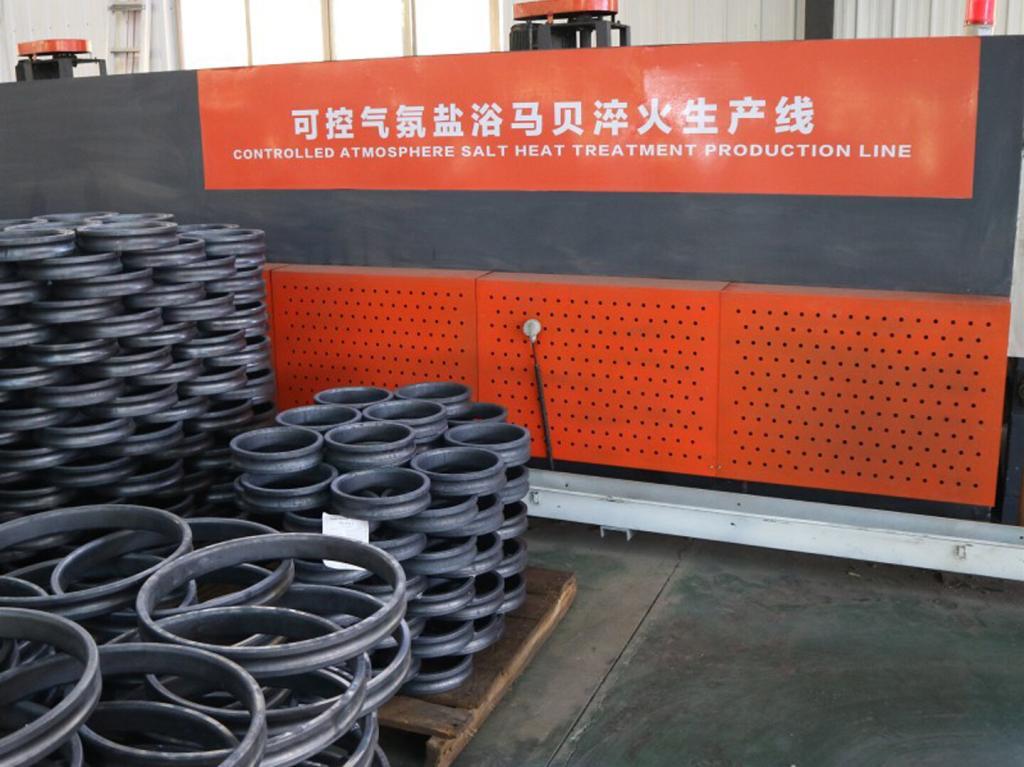

Chromium steel 52100 is the most common material used in the manufacture of precision ball bearings, roller bearings and tapered roller bearings. The chemical composition of chromium steel contains higher carbon content and a chromium content of about 1.5%. Using controlled machining and heat treatment methods, engineers create bearing components that are strong enough to resist cracking and have surfaces that are hard enough to resist rolling contact fatigue beneath the surface.

Ultra-Clean 52100 Chrome Steel Bearings

The raw steel used to produce high-precision miniature bearings undergoes an additional melting step. The result is a steel with a uniform, fine-grained material structure; the bearing contact surfaces can be super smooth, so the bearings are quiet. The most common heat treatment method for chromium steel is to thoroughly harden the steel in a controlled atmosphere furnace. Bearings made of chromium steel can operate continuously at temperatures up to 120°C.

Stainless steel bearings

Stainless steel is used to manufacture bearing components because it has a higher chromium content (~18%) and added nickel, making it resistant to surface corrosion. Chromium reacts with oxygen to form a layer of chromium oxide on the surface, forming a passivation film.

Martensitic stainless steel bearings — AISI 440C

The carbon content in 400 series stainless steel is high enough to be hardened using standard heat treatments up to Rc58. Due to its lower hardness, bearings made from this material have a load-carrying capacity that is 20% lower than 52100 chromium steel bearings. The amount of carbon means the ingredients are magnetic.

Martensitic stainless steel bearings — ACD34 / KS440 / X65Cr13

Many miniature bearing manufacturers make rings and balls out of stainless steel with slightly lower carbon and chromium content than AISI 440C, which has designations such as ACD34, KS440 and X65Cr13. This material has smaller carbides after heat treatment, so the bearings will have superior low noise characteristics while providing the same corrosion resistance as 440C.

Martensitic Stainless Steel Bearings – SV30

Martensitic stainless steels can be modified during raw steel processing by reducing the carbon content and introducing nitrogen as an alloying element. Nitrogen increases the saturation of chromium, which converts to chromium nitride instead of chromium carbide. The result is a high-strength, high-hardness steel with an excellent microstructure that can extend fatigue life by up to 100% in some applications.

Austenitic stainless steel bearings

Bearing components made 300 series stainless steel materials are resistant to corrosion and are non-magnetic due to their low carbon content. The trade-off, however, is that the material cannot harden, so the bearings can only operate at low loads and speeds. The chemical reaction between the bearing surface and oxygen is called a passivation process; the passivation film formed on the surface protects the bearing from corrosion. Bearing caps, sealing washers and ball cages are sometimes made of AISI303 or AISI304 stainless steel because they have moderate corrosion resistance and are better suited to being formed into a variety of shapes.

Plastic and non-metallic material bearings

When you think of bearing materials, the first option that comes to mind is steel. While this is undoubtedly the most common material, there are a range of other options, each with their own unique benefits and limitations. Depending on the type of application, bearing experts may recommend the use of plastic ball bearings. The most common plastic ball bearings have inner and outer rings made from an acetal base material. Balls are usually made of stainless steel, but glass or plastic balls can also be used. Various types of plastic ball bearings are available, including deep groove or Conrad-type bearings, miniature bearings, angular contact bearings, self-aligning bearings and thrust bearings. Plastic bearings offer many advantages over steel or ceramic bearings. The general characteristics of plastic ball bearings are:

• No grease lubrication required.

• Excellent performance in chemical environments. It can be used in water and salt water (full immersion)

• Good temperature range

• Non-magnetic and non-conductive

• Light weight

Phenolic resin – Phenolic resin is artificially synthesized from phenol and formaldehyde thermosetting resins. Because it is produced from a resin similar to phenol-cresol, these types of materials are often referred to as “phenolic resins.” This material is highly resistant to oils and chemicals; it is highly resistant to heat, but has poor resistance to alkalis. It is non-conductive and non-magnetic.

PTFE or Teflon. TEFLON is a registered trademark of DuPont. Features include low surface friction, corrosion and chemical resistance, high heat resistance (wide temperature range of 196 ~ 260 °C), and 0% water absorption. This material is often used in medical devices.

UHMW: UHMW (Ultra High Molecular Weight Polyethylene) is a high molecular weight thermoplastic resin. This special polyethylene is produced through advanced polymerization technology. Features include excellent chemical resistance, low water absorption, excellent abrasion resistance, retention of its performance at low temperatures, and light weight.

PEEK: PEEK is a crystalline thermoplastic. It is a special synthetic aromatic polyetherketone. It has extremely high heat resistance, excellent fatigue resistance, tough wear resistance, strong dimensional stability, excellent chemical resistance, excellent insulation and radiation resistance. Unfortunately, PEEK is very expensive.

Ceramic Bearings

Ceramic bearings belong to a special field of the bearing industry. The most common arrangement is a hybrid bearing, usually with stainless steel rings and ceramic balls. The most commonly used ceramic materials are silicon nitride, zirconia and silicon carbide. The ball made of ceramic material is very hard, up to Rc78, and has a very smooth surface. Today’s engineers have many options when faced with extreme or harsh operating conditions. This rich selection includes the use of ceramic materials that offer many advantages in a variety of applications. The most common use is to produce rolling elements (balls) from ceramic materials, while the inner and outer rings are made of conventional heat-treated steel, chromium steel or stainless steel.

Hybrid bearings combine the advantages of different bearing types to provide improved performance and versatility. They typically integrate ceramic rolling elements with steel races to increase stiffness, durability and corrosion resistance. Hybrid bearings are suitable for a variety of robotic applications that require a balance between high speed, heavy loads and long service life. Hybrid bearings (ceramic balls with stainless steel rings) and all-ceramic bearings are excellent alternatives for operation in vacuum or other harsh environments. The ceramic construction makes them stronger than stainless steel bearings. Ceramic hybrid ball bearings also offer high wear resistance, higher temperature resistance, excellent vibration resistance, high rigidity and no arcing. They are ideal for motor use and last up to five times longer than steel bearings.

Si3N4 Bearings

Stainless steel ring, silicon nitride (Si3N4) ceramic ball with plastic crown ball retainer. The most common configurations feature chrome or stainless steel rings and ceramic balls. Nitrogen reinforced stainless steel ring material is also available. The most common ball ceramic material is silicon nitride, Si3N4. Compared with traditional steel balls, this material has the properties required for rolling bearings, such as:

• Lightweight (about 60% lighter than bearing steel)

• High hardness – over 75 HRc

• Higher modulus of elasticity – stiffer

• Lower coefficient of thermal expansion

• Higher maximum operating temperature – 10000C

• Highly polished surface finish reduces friction

Zirconia Bearings

Balls made of zirconium oxide (ZrO2) are also available. This ceramic material has some similar properties to silicon nitride, but differs in that some of its mechanical and thermal properties are closer to those of the steel alloy from which the rings are made. This is advantageous for maintaining preload and contact angle over a wide operating temperature range.

• Higher stiffness and rigidity, reduced deflection

• Increase top speed, RPM

• Reduces adhesive wear and eliminates the need for cold welding

• Extended lubricant life

• Reduce noise levels and vibrations

• No arcing on the balls

Full ceramic bearings are often the solution for extreme environments such as high temperatures, corrosive chemicals, steam and high vacuum. The inner and outer rings and rolling elements of these bearings are made of ceramic materials. Like the balls in hybrid bearings, the rings in all-ceramic bearings are usually made of silicon nitride, Si3N4, or zirconium oxide, ZrO2. The cage in all-ceramic bearings is usually made high-performance plastics such as PEEK or PTFE.

Robot Bearing Shields vs Seals

For long-lasting operation of the robot, designers can also customize shielding or sealing solutions for the robot bearings. The metal shield has no direct contact with the inner ring, minimizing rotational torque and helping to maximize operating speed. A molded rubber seal (usually made from the trusty nitrile rubber material) contacts the inner ring. Rubber seals provide better protection in contaminated environments than metal shields, but also increase starting and operating torque due to seal resistance. The seal may also reduce the maximum RPM rather than the required RPM level, which must be taken into account. Depending on the bearing type, combined seals/shields provide additional protection. Glass-reinforced PTFE seals have excellent resistance to certain chemical exposures and may be preferred because they also have higher operating speeds and lower torque resistance than rubber seals.

Robot bearing lubrication

obot bearing maintenance and lubrication are both important factors in extending the life of the robot. Regular lubrication with oil or grease minimizes bearing friction and heating, while routine inspections help detect general wear and bearing damage early. Ideally, you should have an advanced monitoring system to assist with this, enhancing bearing fault detection to ensure timely troubleshooting and maintenance. The key function of lubricants is to minimize frictional resistance and wear of the moving parts, which are the balls or rollers and the ring raceways. Lubricants designed for specific operating conditions will provide an appropriate load-bearing, wear-protective film. Ideally these friction surfaces are kept separated by the membrane. In addition, lubricants provide heat dissipation and overall bearing thermal stability. Choosing the right lubricant can avoid rapid deterioration over time and provide protection against corrosion, moisture and contaminant intrusion. For example, in food and beverage processing environments, strict regulatory guidelines often require the use of H1 food-grade lubricants (often containing synthetic hydrocarbon base oils containing urea, polyurea, or aluminum complex thickeners) because of the potential for incidental exposure.

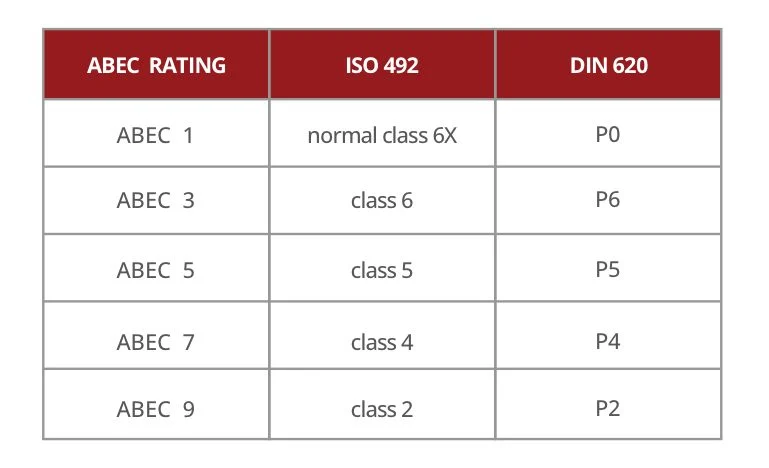

Robot Bearings ABEC Rating

The Bearing Engineering Council (ABEC) establishes acceptable tolerances related to the operating and dimensional accuracy of all bearings. ABEC grades are tolerance classes for bearings that are now a recognized industry standard, so bearing manufacturers must have their products rated by the committee. Technically, all bearings are precision, but there are different levels of accuracy. The system uses odd numbers for classification levels (i.e., 1, 3, 5, 7, and 9), with higher levels indicating tighter tolerances and greater efficiency, accuracy, and speed capabilities.

Most bearings have an ABEC 3 rating. Alternators, vacuum motors, skates, and skateboards require lower ABEC. But if you are looking for a bearing with a higher ultimate speed, choose a rating of 5. Machine quality requires a rating of 7 or 9. Robot bearings are precision bearings with an ABEC rating of 7 or 9. While ABEC grade is just one of many factors in determining the ideal precision bearing for your application, knowing the ABEC grade will help ensure that you don’t purchase a precision bearing that is or less accurate than you need.

Factors for Choosing Robot Bearings

Choosing the right bearings for your robot is a critical step in ensuring optimal performance, reliability and longevity. Engineers can make informed decisions by considering load capacity, speed, accuracy requirements, environmental factors, maintenance requirements and various bearing types.

Rotating speed. One way to select the correct bearing type is to determine the rotational speed for your application. For example, roller bearings are ideal for low-speed tasks, while ball bearings are ideal for high-speed applications.

Lubrication required. The type of lubrication suitable for your application depends on its speed. Lower speed applications benefit from an oil bath, whereas higher speeds may require grease or even oil mist if the n*dm value exceeds the maximum speed allowed by the grease.

Bearing stiffness and runout. It is also important to evaluate the application’s tolerance for bounce deviations. For example, if your application only allows for small fluctuations, ball bearings are the best choice.

load capacity. Roller bearings can handle heavy loads, while ball bearings are better suited to handle small or average loads. Considering the load capacity required for your application will help you choose between these types.

Bearing tolerances. When you buy a batch of bearings, you expect them to all be the same. However, this should not be taken for granted. Tolerance levels and dimensional accuracy vary depending on bearing type, material and brand. It makes sense that any error in the bearing measurements would affect the accuracy of the robot’s movements.

The operating environment, applied loads and expected motion profiles may also influence the bearing material selected. For harsh or corrosive environments (typical of medical, food service, and chemical processing applications), 440C stainless steel is often specified for rings and balls instead of the standard hard chromium steel material.

Conclusion

Aubearing is a rapidly growing bearing company in China, specializing in the development and production of a wide range of high-quality ball and roller bearings for use in robotics and automation, electric motors, gearboxes, ATVs, bicycles, automobiles, power tools and other industrial fields. Aubearing’s customers come from than 40 countries around the world and include well-known automotive OEMs, first-tier suppliers and many other second-tier suppliers. In addition, Aubearing’s thin-section bearings are installed by well-known original equipment manufacturers in numerous industries such as robotics and medical equipment. Aubearing recognizes the growing demand for high-quality precision bearings in robotics and automation. Our team can help you find the perfect bearing product for your specific needs. We provide you with solutions from our vast inventory and provide you with accurate delivery schedules and pricing options. If you are looking for bearings for applications such as automotive, robotics, aerospace, healthcare, machine manufacturing and food processing, the Aubearing team can help.