Bearing Manufacturer & Supplier

Specialize in ball bearings, roller bearings, thrust bearings, thin section bearings etc.

The Ultimate Guide to Miniature Ball Bearings

At Aubearing, we stock a wide range of miniature ball bearings, which are smaller bearings also known as instrument bearings or miniature bearings. These miniature ball bearings are commonly used in power tools and children’s toys, robots, semiconductors, skateboards and skates, etc. Aubearing offers open miniature ball bearings, which allow oil or grease to flow freely through the bearing for lubrication purposes, and sealed and shielded miniature ball bearings, which prevent dust from entering and retain lubricant. You can search our range of miniature ball bearings by type, width, inside diameter or outside diameter, depending on your needs. Upon request, Aubearing also offers a wide range of Abec precision miniature bearings, including Abec grades 5, 7 and 9, designed to meet the needs of a variety of industrial, commercial and consumer applications. Our miniature bearings are available in a variety of sizes, styles and materials including stainless steel, chromium steel and ceramic as well as flanged, extended inner ring and miniature thrust ball bearings to meet your specific requirements.

Table of Contents

ToggleWhat is the definition of miniature ball bearings?

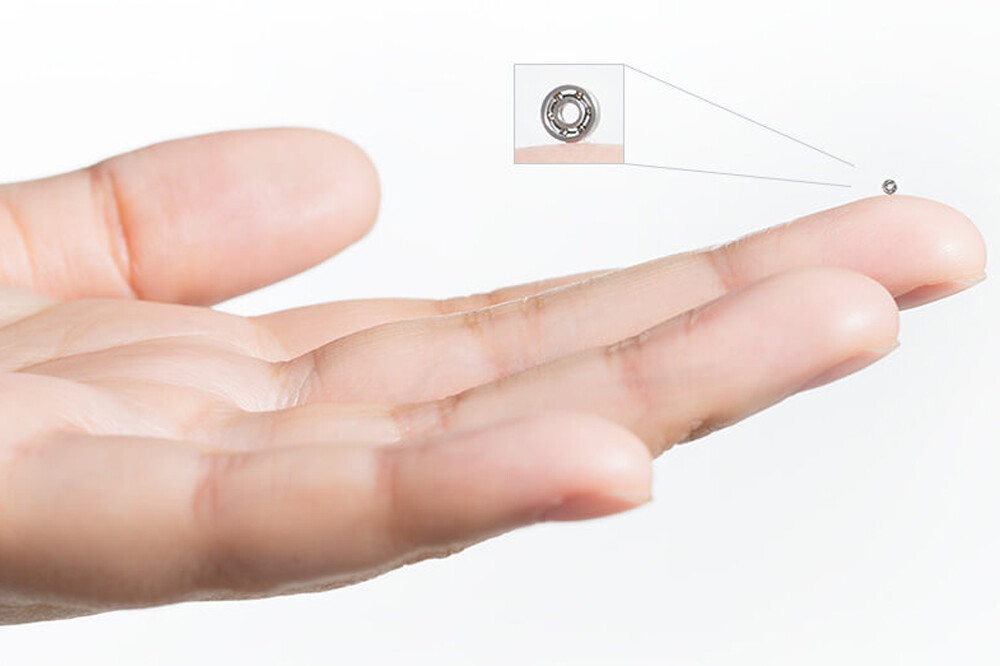

Miniature ball bearings are small deep groove ball bearings whose dimensions make them suitable for special applications. In addition, they enable very high speeds and low noise. Miniature bearings generally consist of outer rings, inner rings, balls and cages. The metric series of miniature bearings, with an outer diameter less than 9mm; the inch series, a general name for various small bearings with an outer diameter less than 9.525mm. The main materials for manufacturing miniature bearings include carbon steel, bearing steel, stainless steel, plastic, ceramics, etc. The minimum inner diameter can be 0.6mm, and generally the inner diameter is 1mm. The accuracy classes of inch size miniature ball bearings range from ABEC0 to ABEC7. Miniature precision ball bearings are suitable for everyday applications as well as the most demanding environments, including high/low temperatures, cryogenics, vacuum, corrosive and high speeds.

Miniature ball bearing version

Single row miniature bearings

The dimensions of single row miniature bearings comply with DIN 625-1. Its inner diameter is less than 10 mm and it is an economical “all-round bearing”.

Miniature flange ball bearings

Miniature flange ball bearings are used for axial fixation with simplified positioning holes with an inner diameter of less than 10 mm.

Full ball miniature bearings

Full complement miniature ball bearings are cageless and accommodate the maximum number of balls, giving them a higher load capacity than caged miniature ball bearings of the same size.

Materials for miniature ball bearings

Bearing steel

Bearing steel (chromium steel) is the most common material for miniature bearings. It is wear-resistant, impact-resistant, electrically conductive, magnetically conductive, and extremely cost-effective. Bearing steel has high load capacity and low noise characteristics. However, miniature/instrument bearings are not suitable for high load applications. The chromium steel bearings can withstand temperatures up to 120°C in continuous use and are equipped with steel cages and proper lubrication. They can also be used intermittently at temperatures up to 150°C. When the temperature is above a certain level, the strength of chromium steel bearings decreases and their dimensions change than stainless steel. Chromium steel is not suitable for use in corrosive environments because it is not corrosion resistant, so many miniature bearings are manufactured from stainless steel.

Stainless steel miniature bearings

Stainless steel (440C, 303, 304, 316) miniature ball bearings are hygienic, corrosion-resistant (to fresh water), lubricated primarily with food-grade grease (identifiable by the suffix -GF), magnetic, can withstand high loads and are suitable for high speeds.

Both stainless steel and chromium steel provide miniature bearings with a high strength-to-wear ratio, which is critical for long service life and efficient operation. Let’s look at the differences/similarities between stainless steel and chromium alloy steel.

Hybrid ceramic miniature bearings

Hybrid bearings with ceramic balls and rings made of stainless steel or rolling bearing steel experience less wear than similarly sized steel ball bearings. Ceramic balls provide electrical insulation, have high-speed operating characteristics, and are lighter than steel balls, so hybrid bearings can withstand higher speeds than pure steel bearings.

Ceramic miniature ball bearings are extremely wear-resistant due to their high hardness, corrosion resistance and durability. They have very good high-speed running performance, are lighter than steel bearings of the same size, are suitable for dry running, are insulated, non-magnetic and resistant to high temperatures.

Micro balls of miniature ball bearings

Miniature precision balls are available in sizes ranging from 1 mm to 3 mm and grades 10 to 50. With a sphericity of only ten millionths (0.00001”) of an inch, a Grade 10 ball is a very accurate ball.

Typical applications of miniature bearings

Micro bearings are suitable for office equipment, micro motors, instrumentation, laser engraving, small watches, soft drives, pressure rotors, dental drills, hard disk motors, stepper motors, video recorder drums, toy models, computer cooling fans, and money counting. machines, fax machines and other related fields.

Miniature bearings help reduce friction between components that need to move independently while effectively saving space in compact applications. For miniature bearings, the important attributes are speed, accuracy and longevity. In addition, the quietness of the bearing when running at high speed is also important. Due to its unique shape, extreme care must be taken when handling. Miniature bearings must be well maintained, lubricated, and stored under clean room conditions to prevent debris from contacting them. They are fragile, tiny, and transparent, and even a thin hair can cause damage to the ball and raceway. They are designed for medium radial and thrust applications at low operating torques.

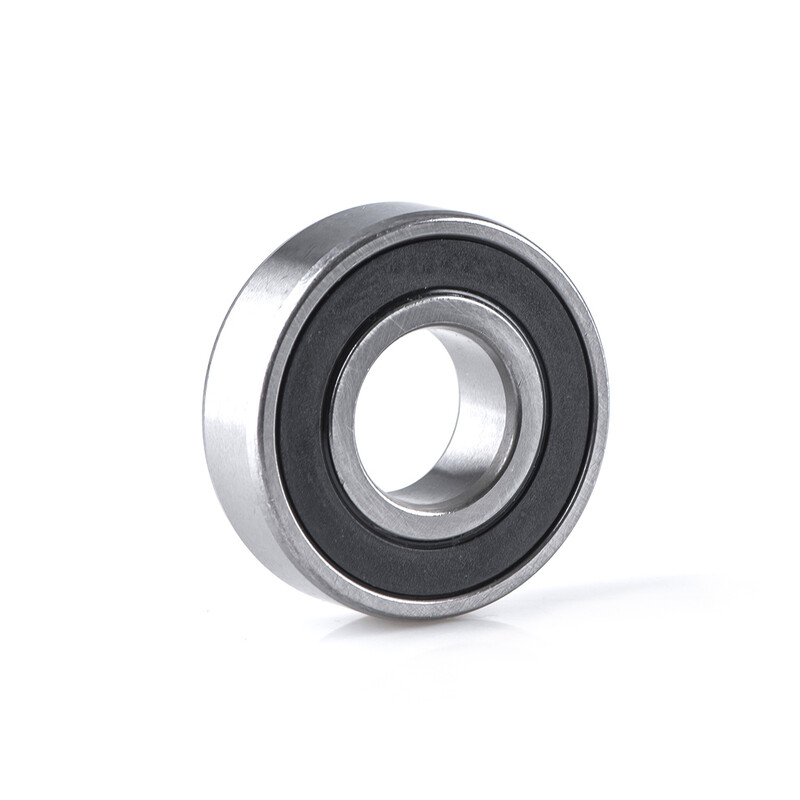

Miniature bearing shields and seals

Miniature ball bearings are available as open bearings or bearings with metal dust shields. Larger sizes of miniature bearings can be equipped with rubber or PTFE contact seals or low-friction non-contact rubber seals. Miniature bearings with retaining rings are used for high-speed rotating parts with low friction torque and for all applications requiring low noise and vibration. The accuracy of miniature bearings is generally P0, P6, P5, P4.

Seal type | ZZ | Metal shields on both sides. |

2RS | Rubber seals on both sides. | |

Z | Metal shield on one side. | |

RS | Rubber seal on one side. | |

Tolerances | P0 | Normal tolerance level. Is not indicated as a standard. |

P6 | Greater tolerance level than P0. | |

P5 | Greater tolerance level than P6. | |

P4 | Greater tolerance level than P5. |

Open miniature bearing caps are capless designs that allow the bearing’s internal components to be exposed to the outside environment. This design makes the bearings susceptible to contamination from dirt, dust, and other external particles. Therefore, miniature bearings are suitable for clean environments or occasions that require regular cleaning.

Shielded miniature bearings refer to bearings with a metal dust cover on the outer cover. The metal shield effectively blocks the entry of dust, contaminants and other external particles while retaining lubricant within the bearing.

Sealed miniature bearings are bearings with a rubber seal on the outer cover. Rubber seals effectively block the entry of moisture, dust and other contaminants, providing enhanced protection. This type of sealing is often used in harsh environments and applications that require stringent protection.

As one of Aubearing’s core products, miniature ball bearings contain than 15 years of precision bearing processing and manufacturing technology. We manufacture up to 8,500 models of miniature and small ball bearings with an outer diameter of less than 30mm, which are suitable for high-speed rotation, low noise, and low vibration. , special environments and other usage conditions, there are rich solutions. The following is the Aubearing miniature bearing size chart.

Item # | (d) Bore Diameter | (D) Outer Diameter | (B) Width | (rs) Minimum Radius | (C) Dynamic Load | (Co) Static Load | (2RS) Lubrication Speed | (Grease) Lubrication Speed | (Oil) Lubrication Speed |

60/2.5/P5 | 2.5 mm | 8 mm | 2.8 mm | N/A | 319 N | 106 N | N/A | 67000 r/min | 80000 r/min |

604 | 4 mm | 12 mm | 4 mm | N/A | 806 N | 280 N | N/A | 53000 r/min | 63000 r/min |

605 | 5 mm | 14 mm | 5 mm | 0.20 mm | 1330 N | 505 N | 25000 min-1 | 40000 min-1 | 50000 min-1 |

606 | 6 mm | 17 mm | 6 mm | 0.30 mm | 2263 N | 845 N | 23000 min-1 | 38000 min-1 | 45000 min-1 |

607 | 7 mm | 19 mm | 6 mm | 0.30 mm | 2838 N | 1078 N | 22000 min-1 | 32000 min-1 | 38000 min-1 |

607 | 7 mm | 19 mm | 6 mm | N/A | 1720 N | 620 N | N/A | 38000 r/min | 45000 r/min |

608 | 8 mm | 22 mm | 7 mm | 0.30 mm | 3369 N | 1363 N | 20000 min-1 | 30000 min-1 | 36000 min-1 |

608 | 8 mm | 22 mm | 7 mm | N/A | 3250 N | 1370 N | N/A | 36000 r/min | 43000 r/min |

609 | 9 mm | 24 mm | 7 mm | 0.30 mm | 3435 N | 1430 N | 20000 min-1 | 32000 min-1 | 36000 min-1 |

609 | 9 mm | 24 mm | 7 mm | N/A | 3710 N | 1660 N | N/A | 32000 r/min | 38000 r/min |

623 | 3 mm | 10 mm | 4 mm | 0.15 mm | 640 N | 220 N | 32000 min-1 | 53000 min-1 | 67000 min-1 |

624 | 4 mm | 13 mm | 5 mm | 0.20 mm | 1290 N | 490 N | 26000 min-1 | 45000 min-1 | 53000 min-1 |

625 | 5 mm | 16 mm | 5 mm | 0.30 mm | 1320 N | 440 N | 24000 min-1 | 35000 min-1 | 42000 min-1 |

626 | 6 mm | 19 mm | 6 mm | 0.30 mm | 2522 N | 1057 N | 22000 min-1 | 32000 min-1 | 38000 min-1 |

627 | 7 mm | 22 mm | 7 mm | 0.30 mm | 3282 N | 1356 N | 20000 min-1 | 34000 min-1 | 36000 min-1 |

628 | 8 mm | 24 mm | 8 mm | 0.30 mm | 3350 N | 1400 N | 20000 min-1 | 24000 min-1 | 32000 min-1 |

629 | 9 mm | 26 mm | 8 mm | 0.30 mm | 4557 N | 1955 N | 19000 min-1 | 30000 min-1 | 34000 min-1 |

634 | 4 mm | 16 mm | 5 mm | 0.30 mm | 1340 N | 525 N | 25000 min-1 | 36000 min-1 | 43000 min-1 |

635 | 5 mm | 19 mm | 6 mm | 0.30 mm | 2336 N | 895 N | 22000 min-1 | 32000 min-1 | 40000 min-1 |

684 | 4 mm | 9 mm | 25 mm | 0.10 mm | 640 N | 225 N | 32000 min-1 | 53000 min-1 | 63000 min-1 |

685 | 5 mm | 11 mm | 3 mm | 0.15 mm | 716 N | 282 N | 26000 min-1 | 45000 min-1 | 53000 min-1 |

687 | 7 mm | 14 mm | 3.5 mm | 0.20 mm | 898 N | 458 N | 20000 min-1 | 31000 min-1 | 40000 min-1 |

688 | 8 mm | 16 mm | 4 mm | 0.20 mm | 1252 N | 592 N | 22000 min-1 | 36000 min-1 | 43000 min-1 |

689 | 9 mm | 17 mm | 4 mm | 0.20 mm | 1378 N | 797 N | 19000 min-1 | 28000 min-1 | 36000 min-1 |

693 | 3 mm | 8 mm | 3 mm | 0.15 mm | 558 N | 180 N | 32000 min-1 | 60000 min-1 | 67000 min-1 |

694 | 4 mm | 11 mm | 4 mm | 0.15 mm | 967 N | 350 N | 30000 min-1 | 43000 min-1 | 56000 min-1 |

695 | 5 mm | 13 mm | 4 mm | 0.20 mm | 1077 N | 432 N | 24000 min-1 | 43000 min-1 | 50000 min-1 |

696 | 6 mm | 15 mm | 5 mm | 0.15 mm | 1082 N | 442 N | 24000 min-1 | 40000 min-1 | 45000 min-1 |

697 | 7 mm | 17 mm | 5 mm | 0.30 mm | 1605 N | 720 N | 22000 min-1 | 36000 min-1 | 43000 min-1 |

698 | 8 mm | 19 mm | 6 mm | 0.30 mm | 2237 N | 917 N | 22000 min-1 | 36000 min-1 | 43000 min-1 |

This chart summarizes a complete list of common miniature bearing sizes, including information on outside diameter (OD), inside diameter (ID), width (W), speed, load, and . Understanding these dimensions is critical to finding the best fit for your application, ensuring optimal performance and space-saving integration.

Factors to consider when choosing miniature bearings

As we all know, miniature bearings are widely used in various precision instruments, robots, semiconductors and other markets. The performance requirements for the operation of miniature bearings are becoming increasingly stringent. Therefore, the conditions and performance required for the quality of miniature bearings are becoming and diverse, which places higher and stringent requirements on bearing manufacturers. Not only does the machining accuracy of bearings increase to a certain level under the conditions of environmental protection requirements, but also higher requirements are put forward for existing production efficiency.

In order to select the appropriate bearing for micro bearings, the layout, accuracy, stiffness, installation and disassembly of the bearing must first be considered. The bearing structure is then determined by considering the allowable space, size and acquisition cost of the bearing. Secondly, I will compare the design and life of the bearing, the durability limit, and sometimes even when choosing a bearing, I usually only focus on the fatigue life of the bearing. But in fact, the quality of the grease will affect the aging and qualitative change of the grease, leading to factors such as bearing heating, wear, noise, etc. This also requires sufficient research and understanding. There is no certain order and rules for the selection of bearings, especially when the bearings are used in the research and development of new machines, special usage conditions and special environmental conditions in the initial stage.

Generally speaking, users are particularly cautious in this case, and they do not quite know which bearing to use. To avoid detours, what are the causes of micro bearing failure? About 30% of miniature bearing failures are caused by dust, dirt, debris contamination and corrosion. Contamination is usually caused by abnormal use and harsh working conditions. It can also cause torque and noise issues. Failure of microbearings due to environment and contamination is foreseeable. Further, the cause of such failures can be determined through simple visual observation. As long as the user unit is used and installed properly, micro-bearing spalling and corrosion can be avoided to a large extent. There are indentations on the micro bearing raceway caused by impact loads or improper installation, which will also produce greater noise, vibration and additional torque.

A leading miniature bearing manufacturer in China

As a leading miniature bearing manufacturer in China, Aubearing fully understands that every application is unique, so we offer a variety of miniature bearing options. Aubearing’s facilities for manufacturing micro balls include cold heading, heat treatment (hardening) and tempering furnaces, high-pressure hardness testers and demagnetization equipment. The China-based facility also offers state-of-the-art ultrasonic cleaning and uses advanced vision equipment to perform 360-degree, 100% inspection of bearing surfaces.

Aubearing’s miniature bearings are manufactured using the highest quality materials and manufacturing techniques to ensure exceptional performance, durability and reliability and include standard catalog bearings, special designs for ultra-high speed operation (500,000 rpm), duplex and super duplex bearings, and Customized solutions for demanding applications. Aubearing offers competitive pricing, fast shipping, and excellent customer service, ensuring you have a positive experience when choosing Aubearing. Whether you need a single miniature bearing or a large order for a production line, Aubearing is your trusted source for all your miniature bearing needs.