Bearing Manufacturer & Supplier

Specialize in ball bearings, roller bearings, thrust bearings, thin section bearings etc.

The Ultimate Guide to Bearing Model Codes

Bearings are key transmission components in mechanical equipment. Correctly selecting and understanding bearing model codes is crucial to the performance and life of mechanical equipment. Therefore, it is very necessary for engineers and technicians to understand and master the meaning of bearing model codes. This article will introduce the components of bearing model codes in detail, including basic codes, size codes, and prefix and suffix codes of bearings of different well-known brands, to help you better understand and apply bearing codes.

Table of Contents

ToggleBearing Basic Codes

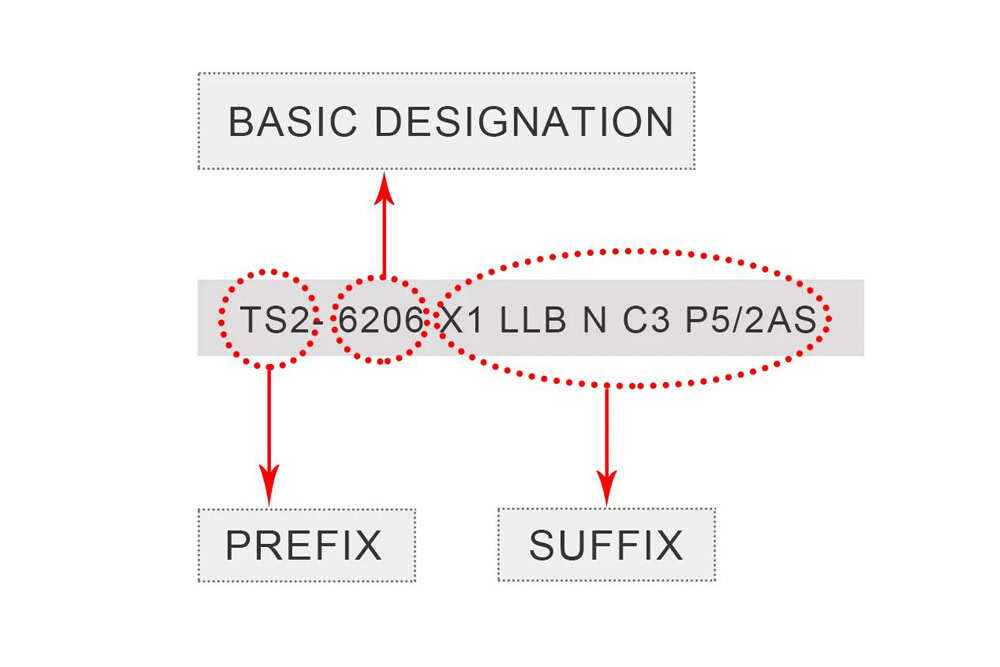

The basic bearing code consists of three parts: bearing type code, size series code, and inner diameter code. Here is a detailed description:

| Basic Code | Type Code | Dimension Series Code | Bore Code | Description |

|---|---|---|---|---|

| 6201 | 6 | 2 | 01 | For example: 6201, 6 represents the type code; 2: dimension series code; 01: bore code |

Bearing Type Codes

The bearing type code is represented by numbers or letters, as follows:

Code | Bearing Type |

0 | Double-row angular contact ball bearings |

1 | Self-aligning ball bearings |

2 | Self-aligning roller bearings and thrust self-aligning roller bearings |

3 | Tapered roller bearings |

4 | Double-row deep groove ball bearings |

5 | Thrust ball bearings |

6 | Deep groove ball bearings |

7 | Angular contact ball bearings |

8 | Thrust cylindrical roller bearings |

N | Cylindrical roller bearings |

U | Insert ball bearings |

QJ | Four-point contact ball bearings |

Bearing size code

The size series code consists of the width series code and the diameter series code:

Diameter series: 7, 8, 9, 0, 1, 2, 3, 4, 5 (outer diameter increases in sequence)

Width series: 8, 0, 1, 2, 3, 4, 5, 6 (width increases in sequence)

Inner diameter code

The inner diameter code indicates the inner diameter of the bearing, as follows:

Bore Diameter | Code | Example |

0.6 to 10mm (non-integer) | Represented by nominal bore diameter in millimeters, separated by a “/” from the dimension series code | Deep groove ball bearing 618/2.5 |

1 to 9mm (integer) | Represented by nominal bore diameter in millimeters | Deep groove ball bearing 625 or 618/5 |

10 to 17mm | 00, 01, 02, 03 | Deep groove ball bearing 6200 (10mm bore) |

20 to 480mm | Quotient of nominal bore diameter divided by 5 | Self-aligning roller bearing 23208 (40mm bore) |

SKF Bearing Prefix Codes

Code | Description | Example |

GS | Housing washer of cylindrical roller thrust bearing | GS81107 – housing washer of thrust cylindrical roller bearing 81107 |

K | Cylindrical roller-cage thrust assembly | K81170 |

K- | Imperial tapered roller bearing inner ring with rollers-cage assembly or outer ring | K-09067 |

L | Inner or outer ring of separable bearing | LNU207 – inner ring of cylindrical roller bearing NU207 |

R | Inner or outer ring of separable bearing with rollers-cage assembly | |

W | Stainless steel deep groove ball bearing | |

WS | Shaft washer of cylindrical roller thrust bearing | |

ZE | Bearings for electrical installation |

SKF Bearing Suffix Codes

Code | Description |

A | Modified internal design, same external dimensions. For example: 4210 A indicates a double row deep groove ball bearing without filling slots; 3220 A indicates a double row angular contact ball bearing with a 30° contact angle |

AC | Single row angular contact ball bearing with a 25° contact angle |

ADA | Improved stop groove on the outer ring, split inner ring with a fixed ring |

B | Modified internal design, same external dimensions. For example: 7224 B indicates a single row angular contact ball bearing with a 40° contact angle; 32210 B indicates a tapered roller bearing with a larger contact angle |

Bxx(x) | Combination of B with a two- or three-digit number, indicating some variants with no suitable suffix. For example: B20 indicates a narrowed width tolerance |

C | Modified internal design, same external dimensions. For example: 21306 C indicates a spherical roller bearing with two pressed steel window-type cages, no flanges on the inner ring, and a guide ring centered on the inner ring |

CA | 1, C-type spherical roller bearing with a machined brass cage, flanges on both sides of the inner ring, and a guide ring centered on the inner ring; 2, universal matched pair bearing, with axial clearance smaller than normal group (CB) |

CAC | Improved guiding of the rollers for CA-type spherical roller bearings |

CB | 1, Universal matched pair bearing with normal axial clearance when arranged back-to-back or face-to-face; 2, double row angular contact ball bearing with specific axial clearance |

CC | 1, C-type spherical roller bearing with improved roller guiding; 2, universal matched pair bearing with axial clearance greater than normal group (CB) when arranged back-to-back or face-to-face |

CLN | Tapered roller bearing with narrowed width and total width tolerance band |

CL0 | Accuracy complies with ANSI/ABMA 19.2:1994 tolerance class 0, used for imperial tapered roller bearings |

CL00 | Accuracy complies with ANSI/ABMA 19.2:1994 tolerance class 00, used for imperial tapered roller bearings |

CL3 | Accuracy complies with ANSI/ABMA 19.2:1994 tolerance class 3, used for imperial tapered roller bearings |

CL7C | Tapered roller bearings with special friction characteristics and higher rotational accuracy |

CN | Normal radial clearance, usually used only in combination with the following letters to indicate narrower or shifted clearance ranges |

CV | Improved internal design, full complement cylindrical roller bearing |

SKF Improved Design Codes

Code | Description |

A | Modified internal design, same external dimensions. For example: 4210 A indicates a double row deep groove ball bearing without filling slots; 3220 A indicates a double row angular contact ball bearing with a 30° contact angle |

AC | Single row angular contact ball bearing with a 25° contact angle |

ADA | Improved stop groove on the outer ring, split inner ring with a fixed ring |

B | Modified internal design, same external dimensions. For example: 7224 B indicates a single row angular contact ball bearing with a 40° contact angle; 32210 B indicates a tapered roller bearing with a larger contact angle |

Bxx(x) | Combination of B with a two- or three-digit number, indicating some variants with no suitable suffix. For example: B20 indicates a narrowed width tolerance |

C | Modified internal design, same external dimensions. For example: 21306 C indicates a spherical roller bearing with two pressed steel window-type cages, no flanges on the inner ring, and a guide ring centered on the inner ring |

CA | 1, C-type spherical roller bearing with a machined brass cage, flanges on both sides of the inner ring, and a guide ring centered on the inner ring; 2, universal matched pair bearing, with axial clearance smaller than normal group (CB) |

CAC | Improved guiding of the rollers for CA-type spherical roller bearings |

CB | 1, Universal matched pair bearing with normal axial clearance when arranged back-to-back or face-to-face; 2, double row angular contact ball bearing with specific axial clearance |

CC | 1, C-type spherical roller bearing with improved roller guiding; 2, universal matched pair bearing with axial clearance greater than normal group (CB) when arranged back-to-back or face-to-face |

CLN | Tapered roller bearing with narrowed width and total width tolerance band |

CL0 | Accuracy complies with ANSI/ABMA 19.2:1994 tolerance class 0, used for imperial tapered roller bearings |

CL00 | Accuracy complies with ANSI/ABMA 19.2:1994 tolerance class 00, used for imperial tapered roller bearings |

CL3 | Accuracy complies with ANSI/ABMA 19.2:1994 tolerance class 3, used for imperial tapered roller bearings |

CL7C | Tapered roller bearings with special friction characteristics and higher rotational accuracy |

SKF Bearing Clearance Codes

Code | Description |

C1 | Radial clearance smaller than C2 |

C2 | Radial clearance smaller than normal group (CN) |

C3 | Radial clearance larger than normal group (CN) |

C4 | Radial clearance larger than C3 |

C5 | Radial clearance larger than C4 |

C02 | Narrowed inner ring rotational accuracy tolerance |

C04 | Narrowed outer ring rotational accuracy tolerance |

C08 | C02 + C04 |

C083 | C02 + C04 + C3 |

C10 | Narrowed bore and outer diameter tolerance |

CNH | Narrowed clearance range, corresponding to the upper half of the normal group clearance range |

CNM | Narrowed clearance range, corresponding to half of the normal group clearance range |

CNL | Narrowed clearance range, corresponding to the lower half of the normal group clearance range |

CNP | Shifted clearance range, corresponding to the upper half of the normal group clearance range and the lower half of the C3 clearance range |

CNR | Cylindrical roller bearings with normal group clearance as per DIN 620-4:1982 |

Letters H, M, L, and P apply to combinations with the following clearance groups: C2, C3, C4, and C5 |

SKF Bearing Sealing Codes

Code | Description |

RS | Bearing with one side fitted with (or without) a steel skeleton nitrile rubber (NBR) contact seal |

RS1 | Bearing with one side fitted with a steel skeleton nitrile rubber (NBR) contact seal |

RS1Z | Bearing with one side fitted with a steel skeleton nitrile rubber (NBR) contact seal and the other side with a pressed steel dust cover |

RS2 | Bearing with one side fitted with a steel skeleton fluororubber (FPM) contact seal |

RSH | Bearing with one side fitted with a steel skeleton nitrile rubber (NBR) contact seal |

RSL | Bearing with one side fitted with a steel skeleton nitrile rubber (NBR) low friction seal |

RZ | Bearing with one side fitted with a steel skeleton nitrile rubber (NBR) low friction seal |

2RS | Bearing with both sides fitted with (or without) a steel skeleton nitrile rubber (NBR) contact seal |

2RS1 | Bearing with both sides fitted with a steel skeleton nitrile rubber (NBR) contact seal |

2RS2 | Bearing with both sides fitted with a steel skeleton fluororubber (FPM) contact seal |

2RSH | Bearing with both sides fitted with a steel skeleton nitrile rubber (NBR) contact seal |

2RSL | Bearing with both sides fitted with a steel skeleton nitrile rubber (NBR) low friction seal |

2RZ | Bearing with both sides fitted with a steel skeleton nitrile rubber (NBR) low friction seal |

Z | Bearing with one side fitted with a pressed steel dust cover |

2Z | Bearing with both sides fitted with pressed steel dust covers |

2F | Bearing with both sides fitted with standard contact seals and additional normal flinger |

2LS8 | Bearing with both sides fitted with reinforced synthetic rubber contact seals |

2RF | Bearing with both sides fitted with standard contact seals and additional rubber lip flinger |

2RS1 | Bearing with both sides fitted with reinforced nitrile rubber contact seals |

VP076 | Bearing with both sides fitted with pressed steel dust covers |

CS | Bearing with one side fitted with a steel skeleton nitrile rubber (NBR) contact seal |

CS2 | Bearing with one side fitted with a steel skeleton fluororubber (FPM) contact seal |

CS5 | Bearing with one side fitted with a steel skeleton hydrogenated nitrile rubber (HNBR) contact seal |

2CS | Bearing with both sides fitted with a steel skeleton nitrile rubber (NBR) contact seals |

2CS2 | Bearing with both sides fitted with a steel skeleton fluororubber (FPM) contact seals |

2CS5 | Bearing with both sides fitted with a steel skeleton hydrogenated nitrile rubber (HNBR) contact seals |

SKF Bearing Preload Codes

Code | Description |

A | Light preload (2) |

B | Medium preload (2) |

C | Heavy preload (2) |

CA | Small axial clearance (1, 2) |

CB | Normal axial clearance (1, 2) |

CC | Large axial clearance (1, 2) |

C | Special axial clearance, indicated with a number in μm |

GA | Light preload (1) |

GB | Medium preload (1) |

G | Special preload load |

GA | Universal paired bearing with light preload in back-to-back or face-to-face arrangement |

GB | Universal paired bearing with medium preload in back-to-back or face-to-face arrangement |

GC | Universal paired bearing with heavy preload in back-to-back or face-to-face arrangement |

SKF Bearing Pairing Codes

Code | Description |

DF | Two single row deep groove ball bearings, single row angular contact ball bearings or single row tapered roller bearings paired face-to-face |

DT | Two single row deep groove ball bearings, single row angular contact ball bearings or single row tapered roller bearings paired in tandem |

G | Universal paired single row angular contact ball bearings, with a certain preload when arranged face-to-face or back-to-back |

GA | Face-to-face or back-to-back arrangement with light preload |

GB | Face-to-face or back-to-back arrangement with medium preload |

GC | Face-to-face or back-to-back arrangement with heavy preload |

SKF Bearing Grease Codes

Code | Description |

G.. | Used to indicate the grease used in the bearing. The second letter indicates the temperature range of the grease, and the third letter indicates a specific type of grease. |

| Second Letter: |

| – E: Extreme pressure grease |

| – F: Food compatible grease |

| – H, J: High temperature grease, -20 to +130°C |

| – L: Low temperature grease, -50 to +80°C |

| – M: Medium temperature grease, -30 to +110°C |

| – W, X: Low/high temperature grease, -40 to +140°C |

|

|

| Fill Quantity: |

| – Numbers following the three-letter grease code indicate different fill quantities. |

| – 1, 2, 3: Less than standard fill quantity |

| – 4, 5, 6, 7, 8, 9: than standard fill quantity |

Example | GEA: Extreme pressure grease, standard fill quantity |

Example | GLB2: Low temperature grease, 15% to 25% fill quantity |

GJN | Polyurea thickened grease, NLGI consistency 2, operating temperature range -30 to +150°C |

SKF Bearing Surface Hardening Codes

Code | Description |

HA | Surface-hardened bearing or bearing component |

HB | Bainite-hardened bearing or bearing component |

HC | Ceramic material bearing or bearing component |

HE | Bearing or bearing component made of vacuum remelted steel |

HM | Martensite-hardened bearing or bearing component |

HN | Bearing or bearing component with special surface treatment |

HT | Used to indicate the high-temperature grease used in the bearing |

HV | Hardenable stainless steel bearing or bearing component |

SKF Bearing Cage Codes

Code | Description |

H | Hardened snap-type pressed steel cage |

M | Machined brass cage, roller guided |

MA | Machined brass cage, outer ring guided |

MB | Machined brass cage, inner ring guided |

ML | One-piece window-type brass cage, inner ring or outer ring guided |

MP | One-piece window-type brass cage, openings formed by milling, broaching or drilling, inner ring or outer ring guided |

MR | One-piece window-type brass cage, roller guided |

MT | Used to indicate the medium-temperature grease used in the bearing |

N | Outer ring with locating slot |

NR | Outer ring with locating slot and snap ring |

N1 | Outer ring with one positioning slot |

N2 | Outer ring with two positioning slots at 180° |

J | Pressed steel cage, roller guided, not hardened, sometimes followed by a number to indicate different designs, such as J1 |

JR | Cage connected by rivets, made of two flat steel plates, not hardened |

P | Injection-molded glass fiber reinforced nylon 6,6 cage, roller guided |

PH | Injection-molded polyetheretherketone (PEEK) cage, roller guided |

PHA | Injection-molded polyetheretherketone (PEEK) cage, outer ring guided |

T | Machined fiber-reinforced phenolic resin cage, roller guided |

TB | Window-type fiber-reinforced phenolic resin cage, inner ring guided |

TH | Snap-type fiber-reinforced phenolic resin cage, roller guided |

TN | Injection-molded nylon 6,6 cage, roller guided |

TNH | Injection-molded polyetheretherketone (PEEK) cage, roller guided |

TNHA | Injection-molded glass fiber reinforced nylon 6,6 cage, outer ring guided |

TN9 | Injection-molded glass fiber reinforced nylon 6,6 cage, roller guided |

Y | Pressed brass cage, roller guided, sometimes followed by a number to indicate different designs, such as Y1 |

SKF Bearing Tolerance Codes

Code | Description |

P0 | Dimensional and rotational accuracy complies with ISO tolerance class 0 |

P6 | Dimensional and rotational accuracy complies with ISO tolerance class 6 |

P5 | Dimensional and rotational accuracy complies with ISO tolerance class 5 |

P4 | Dimensional and rotational accuracy complies with ISO tolerance class 4 |

P2 | Dimensional and rotational accuracy complies with ISO tolerance class 2 |

P62 | P6 + C2 |

P63 | P6 + C3 |

U | A number following U indicates a narrowed width tolerance band, used for tapered roller bearings or their inner or outer rings. For example: U2: width tolerance +0.05/0mm; U4: width tolerance +0.10/0mm |

SKF Bearing Heat Treatment Codes

Code | Description |

S0 | Special heat treatment, bearing rings remain dimensionally stable at temperatures up to +150°C |

S1 | Special heat treatment, bearing rings remain dimensionally stable at temperatures up to +200°C |

S2 | Special heat treatment, bearing rings remain dimensionally stable at temperatures up to +250°C |

S3 | Special heat treatment, bearing rings remain dimensionally stable at temperatures up to +300°C |

S4 | Special heat treatment, bearing rings remain dimensionally stable at temperatures up to +350°C |

SKF Special Bearing Codes

Code | Description |

V | Full complement bearing (without cage) |

V… | A letter following V indicates a specific feature different from the standard bearing. A three- or four-digit number following V indicates its specific meaning. For example: VA: indicates a specific application; VB: dimensional differences; VE: external or internal differences; VL: coating; VQ: different quality and tolerance; VS: clearance and preload; VT: lubrication; VU: various other features |

VA201 | Bearings for high-temperature applications (e.g., kiln trucks) |

VA208 | Bearings for high-temperature applications |

VA228 | Bearings for high-temperature applications |

VA301 | Bearings for railway traction motors |

VA305 | VA301 + special inspection procedures |

VA3091 | VA301 + VL0241 |

VA350 | Bearings for railway axleboxes |

VA405 | Bearings for vibrating machinery |

VA406 | Bearings for vibrating machinery, bore with PTFE coating |

VA820 | Bearings for railway axleboxes in compliance with EN 12080:1998 |

VC025 | Bearing components treated with fragmentation heat treatment for severe contamination working environments |

VE240 | CARB bearings allowing greater axial displacement |

VE447 | Bearing ring with three evenly distributed threads on one side for lifting device connection |

VE552 | Outer ring with three evenly distributed threaded holes on one side for lifting device connection |

VE553 | Outer ring with three evenly distributed threaded holes on both sides for lifting device connection |

VE632 | Seat ring with three evenly distributed threaded holes on one side for lifting device connection |

VG114 | Surface-hardened pressed steel cage |

VH | Full complement bearing with design to prevent roller slippage |

VL0241 | Outer ring outer surface with aluminum oxide coating, insulation up to 1000VDC |

VL2071 | Inner ring outer surface with aluminum oxide coating, insulation up to 1000VDC |

VQ015 | Inner ring with concave raceway, allowing greater misalignment |

VQ424 | Higher rotational accuracy than C08 |

VT143 | Filled with extreme pressure (EP) grease |

SKF Bearing Lubrication Hole Codes

Code | Description |

W | Outer ring without lubrication groove and hole |

WT | Used to indicate the wide temperature grease used in the bearing (-40 to +160°C). Different greases within this temperature range are indicated with a two-digit number following WT. Different fill quantities are indicated with a letter or a letter-number combination following WT, using the same codes as HT. For example: WT or WTF1 |

W20 | Outer ring with three lubrication holes |

W26 | Inner ring with six lubrication holes |

W33 | Outer ring with lubrication groove and three lubrication holes |

W33X | Outer ring with lubrication groove and six lubrication holes |

W513 | Outer ring with lubrication groove and three lubrication holes, and inner ring with six lubrication holes |

W64 | Bearing with solid oil |

W77 | Outer ring with lubrication groove and three lubrication holes plugged with grease fittings |

X | 1, Dimensional modifications according to ISO standards; 2, Cylindrical roller surfaces (roller bearings) |

SKF Bearing Material Codes

Code | Description |

HV | Stainless steel bearing components, food-grade grease |

VA201 | Bearing with pressed steel cage, suitable for high-temperature applications |

VA228 | Bearing with Coronet graphite cage, suitable for temperatures from -150 to +350°C |

VE495 | Galvanized inner and outer rings and stainless steel oil slinger, food-grade grease |

VL065 | Galvanized bore and side surfaces |

VT357 | Bearing filled with premium mineral oil-based grease made of lithium complex soap |

SKF Bearing Other Features Codes

Code | Description |

C | Cylindrical outer diameter |

U | Bearing without eccentric locking collar |

W | Bearing outer ring without lubrication hole |

W64 | Solid oil bearing |

Q | Optimized contact geometry and surface treatment for tapered roller bearings |

R | 1, Outer ring with flange; 2, Arc-shaped roller surface (roller bearings) |

K | Tapered bore, taper 1:12 |

K30 | Tapered bore, taper 1:30 |

L4B | Special surface coating for bearing rings and rollers |

L5B | Special surface coating for rollers |

L5DA | NoWear bearings with ceramic-coated rollers |

L7DA | NoWear bearings with ceramic-coated rollers and inner ring raceway |

FAG Bearing Suffix Codes

Code | Description |

F | Steel solid cage, roller guided |

FA | Steel solid cage, outer ring guided |

FAS | Steel solid cage, outer ring guided with lubrication groove |

FB | Steel solid cage, inner ring guided |

FBS | Steel solid cage, inner ring guided with lubrication groove |

FH | Steel solid cage, carburized and quenched |

P5 | Tolerance class 5 as per ISO international standard |

P4 | Tolerance class 4 as per ISO international standard |

P2 | Tolerance class 2 as per ISO international standard (excluding tapered roller bearings) |

NSK Bearing Prefix Codes

Code | Description |

F | Flanged outer ring deep groove ball bearings (for d < 10mm), e.g., F605 |

HR | High load capacity tapered roller bearings, e.g., HR30207J |

NSK Bearing Suffix Codes

Code | Description |

A | Bearing with different internal design |

A | Angular contact ball bearing, 30° contact angle |

A5 | Angular contact ball bearing, 25° contact angle |

Z, ZS | One side with steel plate dust cover |

ZZ, ZZS | Both sides with steel plate dust covers |

D, DU | One side with contact rubber seal |

C1 | Radial clearance smaller than C2 |

C2 | Radial clearance smaller than normal |

CN | Normal radial clearance |

C3 | Radial clearance larger than normal |

C4 | Radial clearance larger than C3 |

NTN Bearing Prefix Codes

Code | Description |

B | 40° contact angle |

A | 25° contact angle |

C | 15° contact angle |

J | Pressed steel cage |

NTN Bearing Suffix Codes

Code | Description |

DB | Back-to-back arrangement |

DF | Face-to-face arrangement |

CS | Radial clearance larger than normal |

TIMKEN Bearing Suffix Codes

Code | Description |

AB | Outer ring with flange, outer ring not interchangeable with basic model |

AC | Inner ring with different bore and corner radius |

AD | Double outer ring not interchangeable with basic model |

CR | Outer race with flanges |

CX | Inner ring dimensions different from basic model, not interchangeable |

D | Double inner or outer rings not interchangeable with basic model |

INA Bearing Suffix Codes

Code | Description |

P | Bearing with seal on one side |

PP | Bearing with seals on both sides |

RS | Bearing with contact seal on one side |

2RS | Bearing with contact seals on both sides |

P6 | Bearing with higher dimensional and geometric accuracy |

P5 | Bearing with high dimensional and geometric accuracy |

P4 | Bearing with very high dimensional and geometric accuracy |

KOYO Bearing Prefix Codes

Code | Description |

4CRI | Four-row cylindrical roller bearing inner ring, e.g., 4CRI4560 |

4CRO | Four-row cylindrical roller bearing outer ring, e.g., 4CRO660 |

FE | Magneto ball bearing, positive outer diameter tolerance, e.g., E10 |

EN | Magneto ball bearing, negative outer diameter tolerance, e.g., EN10 |

KOYO Bearing Suffix Codes

Code | Description |

A | Angular contact bearing, 30° contact angle (not marked), e.g., 7210 |

B | Angular contact bearing, 40° contact angle, e.g., 7210B |

C | Angular contact bearing, 15° contact angle, e.g., 7210C |

RSC | RS-type seal made of silicone rubber, e.g., 6210RSC |

RSD | RS-type seal made of polypropylene rubber, e.g., 6210RSD |

RSE | Single-sided, flange-guided contact synthetic rubber seal, e.g., 6206RSE |

2RS | Double-sided, RS-type seal, e.g., 6210-2RS |

2RSN | Double-sided, RS-type seal with snap ring groove, e.g., 6210-2RSN |

ZZ | Double-sided, steel plate dust cover, e.g., 6208ZZ |

NR | Outer ring with snap ring groove, e.g., 6208NR |

NNR | Outer ring with double snap ring grooves |