Bearing Manufacturer & Supplier

Specialize in ball bearings, roller bearings, thrust bearings, thin section bearings etc.

The Ultimate Guide to 6203 Bearings

6203 bearings are typical deep groove ball bearing. It has the advantages of easy disassembly, low friction and versatility, and has become one of the most commonly used bearing types. The 6203 bearing type is used in different industries, from high-precision robotic equipment to the automotive sector. The 6203 bearing looks like a traditional bearing. The running ball completely adapts to the size of the raceway and is composed of an outer ring, an inner ring, balls and a cage. Due to its flat inner and outer ring surfaces, 6203 bearings have a larger contact area, providing high load capacity and better performance, reducing noise and vibration while providing the strength to withstand axial loads.

Table of Contents

Toggle6203 bearing information

specifically, 6203 ball bearings are widely used in industrial and automation applications. They are designed to reduce rotational friction and support loads. The load is evenly distributed across the 25 balls, and when the inner bearing race rotates, the balls also rotate. Since there is point contact between the ball and the track, it can bear bidirectional axial load as well as radial load. Usually used in pairs under normal circumstances to reduce the internal axial force caused by the load and use radial load.

Part Number | 6203 | Static Radial Load | 4800 N |

System of Measurement | Metric | Max Speed (X1000 rpm) | 17 |

Bearing Type | Ball | Lubrication | Required |

For Load Direction | Radial | Shaft Mount Type | Press Fit |

Construction | Single Row | Temperature Range | -30° to 110 °C |

Seal Type | Open | ABEC Rating | ABEC-1 |

Bore Dia | 17 mm | Radial Clearance Trade No. | C0 |

Bore Dia Tolerance | -0.008mm to 0 | Radial Clearance | 0.003mm to 0.018mm |

Outer Dia | 40 mm | RoHS | Compliant |

Outer Dia Tolerance | -0.011mm to 0 | Ball Dia | 6.747mm |

Width | 12 mm | Ball Qty | 8 |

Width Tolerance | -0.120mm to 0 | Weight | 65 g |

Ring Material | 52100 Chrome Steel | Static Radial Load | 4800 N |

Ball Material | 52100 Chrome Steel | Cage Material | 300 Series Stainless Steel |

The 6203 bearing dimension is an inner diameter of 17mm and can accommodate 17mm bearings.

The outer diameter of 6203 bearings is 40 mm. Please make sure your application space can accommodate the outer diameter of 6203.

The width of the 6203 bearing is 12 mm. This refers to the distance between the inner and outer rings of the bearing. Make sure this width is appropriate for your application to ensure proper installation and operation.

Interchange numbers for 6203 bearings:

CG425, 6203RS, 6203LLU, 6203LLB, 6203DDU, 6203VV, 6203.2RSJ1, 6203EE, 6203.2RU, 6203LHX3, 203PP, 203KSZZ, 6203-2NSL, 99203, 6L0 25, 5972K44, 6153K77 , 6203-2NSE, 6203.2RSR, 6203-2RS, 62032RS

6203 deep groove ball bearing sealing and shielding

Shielded bearings have a metal shield on one or both sides of the bearing to provide a physical barrier against larger foreign particles. The guard is not in direct contact with the inner ring, creating a small gap. Therefore, the starting torque of the bearing is smaller. Dust-proof bearings include dust-proof bearings with stamped metal covers and dust-proof bearings with snap rings (also known as ZZNR bearings). Most bearings with dust shields fall into the former category.

Sealed bearings feature non-metallic seals on one or both sides. These seals, typically made of rubber or synthetic materials, create a tight barrier that limits the entry of contaminants better than shield seals. Sealed sealed bearings ensure longer, efficient, less hassle-free performance of mechanical systems and equipment. They are widely used in precision industries, such as the food and beverage industry or the medical industry, where cleanliness is prioritized over minor losses in efficiency.

6203 deep groove ball bearing is an open bearing.

6203Z ball bearings have single row raceways and single shielding.

6203ZZ ball bearings have a single row of raceways with guards on each side. B6203DDU, 6203DDU, 6203LLU, 6203-2NSE, 6203H2RS ball bearings are shielded by two rubber seals on each side.

6203 bearing material

The type of bearing material used will determine the bearing’s service life, reliability and performance. However, there are many factors that affect bearing performance, including the selection of load-carrying capacity, rolling contact conditions, cleanliness of the operating environment and dimensional stability of bearing components. The 6203 deep groove ball bearings manufactured by AUB are made of high-quality carbon chromium steel (Gcr15). Stainless steel bearings can also be customized according to your requirements.

6203 hybrid ceramic bearings are designed to meet the requirements of particularly demanding applications. The inner and outer rings are made of chromium steel 52100 or stainless steel 440C, while the balls are made of ceramic (Si3N4).

Factors affecting the quality of 6203 bearings

There are many factors that affect bearing quality. AUB has summarized the following factors based on years of manufacturing bearing quality:

Steel Grade: The steel used in the manufacturing process plays a vital role in determining bearing life and durability. The simple description “GCR15” only describes the composition range of the steel used. The quality of materials used varies from factory to factory. At this convenience, AUB uses international standard GCR15 bearing steel and SGS-tested stainless steel that meets international standards to manufacture high-quality 6203 bearings.

Bearing components: The quality of the balls, cage/seals, lubricant (grease, even rust-proof oil) plays an important role in making a quality bearing.

Design consistency: The closer a bearing is to the dimensional accuracy of the bearing design standard, the better its performance and longer its life will be.

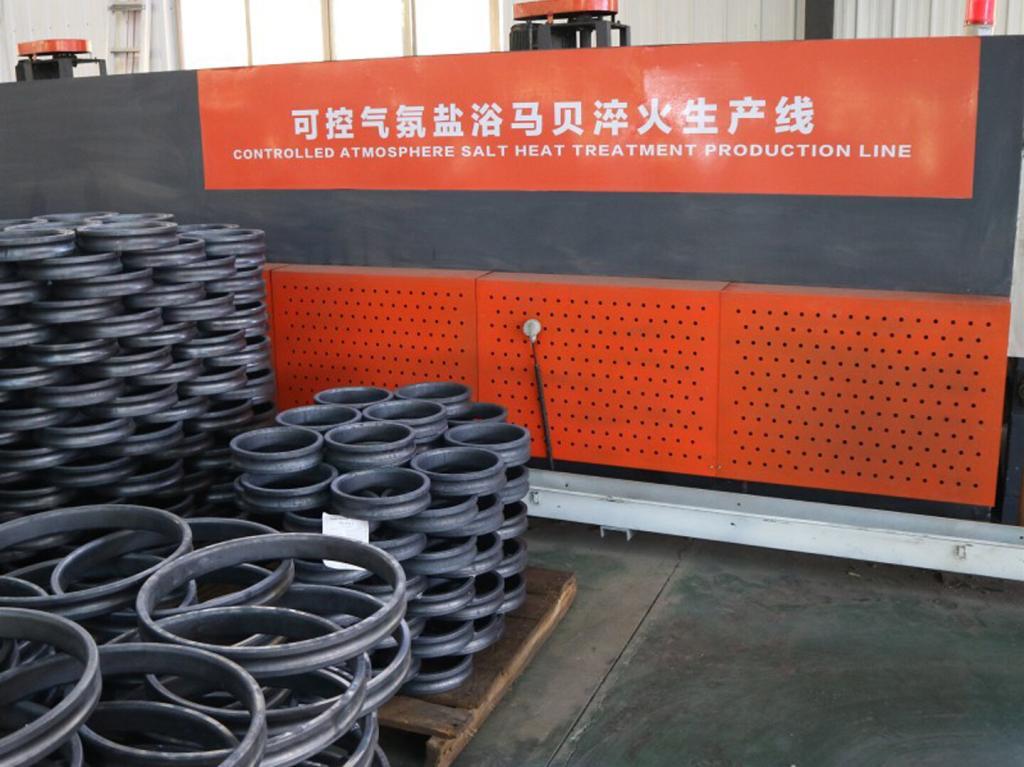

Heat treatment: Bearing steel is usually purchased in an unhardened state. Heat treatment is an important part of the bearing manufacturing process. The process of hardening the bearings maintains durability. AUB has invested a lot of money to purchase heat treatment equipment. Its production line is the same as SKF’s heat treatment equipment, which can ensure the manufacture of high-quality 6203 bearings.

Grinding: The inner and outer ring raceways of the bearing need to be thoroughly ground through multiple cycles to ensure that the rolling element surface is smooth. This is an important step in ensuring bearing tolerances. AUB has purchased 50+ CNC grinding machines, which can produce ABEC “7” or “9” high-quality bearings.

Cleaning: GCR15 bearing steel has excellent hardness and wear resistance. It also exhibits good fatigue life in rolling bearings. However, the corrosion resistance of chromium steel is poor due to its low chromium content. Bearing surfaces must be thoroughly cleaned and coated with rust inhibitor or oil to prevent oxidation. Even slight humidity or moisture exposure can cause surface rust on bearings.

Assembly and Bearing Handling: Bearings must be handled with care. Few factories are able to automate all processes involved to reduce human intervention and ensure cleanliness and hygiene.

Management: The attitude of top management towards strict compliance and quality control is critical to the quality of the bearings produced. AUB has passed ISO9001 and ISO13485 quality certification and is able to enforce strict discipline and attention to detail.

Application of 6203 bearings

6203 metric ball bearings are used in a wide range of applications, from electric motors to washing machines, belt drives, compressors, pumps, turbines, printing and textile machines, automotive, conveyors, light industrial applications, engines, small spindles, food processing, power transmission, rolling mills wait.

Other Popular Products

Bearing No. | Bore(d) | Outer(D) | Width(B) | r | Dynamic(C) | Static(Co) | Weight |

mm | kgf | g | |||||

10 | 26 | 8 | 0,5 | 360 | 196 | 19 | |

12 | 28 | 8 | 0.5 | 400 | 229 | 22 | |

15 | 32 | 9 | 0.5 | 440 | 263 | 30 | |

17 | 35 | 10 | 0.5 | 470 | 296 | 39 | |

25 | 47 | 12 | 1 | 790 | 525 | 80 | |

30 | 55 | 13 | 1.5 | 1030 | 740 | 116 | |

12 | 32 | 10 | 1 | 535 | 305 | 37 | |

15 | 35 | 11 | 1 | 600 | 360 | 45 | |

20 | 47 | 14 | 1.5 | 1000 | 635 | 106 | |

15 | 42 | 13 | 1.5 | 895 | 545 | 82 | |

15 | 19 | 5 | 0.5 | 135 | 75 | 5 | |

15 | 24 | 5 | 0.5 | 163 | 107 | 7 | |

17 | 26 | 5 | 0.5 | 206 | 135 | 8 | |

25 | 37 | 7 | 0.5 | 300 | 234 | 22 | |

30 | 42 | 7 | 0.5 | 355 | 285 | 26 | |

10 | 22 | 6 | 0.5 | 212 | 117 | 10 | |

12 | 24 | 6 | 0.5 | 227 | 133 | 11 | |

15 | 28 | 7 | 0.5 | 340 | 205 | 17 | |

20 | 37 | 9 | 0.5 | 500 | 330 | 36 | |

30 | 47 | 9 | 0.5 | 570 | 430 | 45 | |