Bearing Manufacturer & Supplier

Specialize in ball bearings, roller bearings, thrust bearings, thin section bearings etc.

Railway Bearing

Rail transport is a rapidly growing industry. Bearings are also indispensable in railway production and application industries. Bearings used in the railway industry must have high load carrying capacity and safety performance. Railway bearing application Railway, axle bearing railway locomotive, rolling stock axle system adopts different structural designs due to different application conditions. Both locomotives and passenger cars have axle boxes through which the bearings are connected to the bogie. The railway wagon has no axle box, and the approach road is connected by a saddle. The bearing bears the impact load generated between the wheel set and the bogie, and also bears the axial load generated by the turning of the vehicle. The hub bearing structure includes cylindrical roller bearings, cylindrical roller bearing units, tapered roller bearings, and tapered roller bearing units.

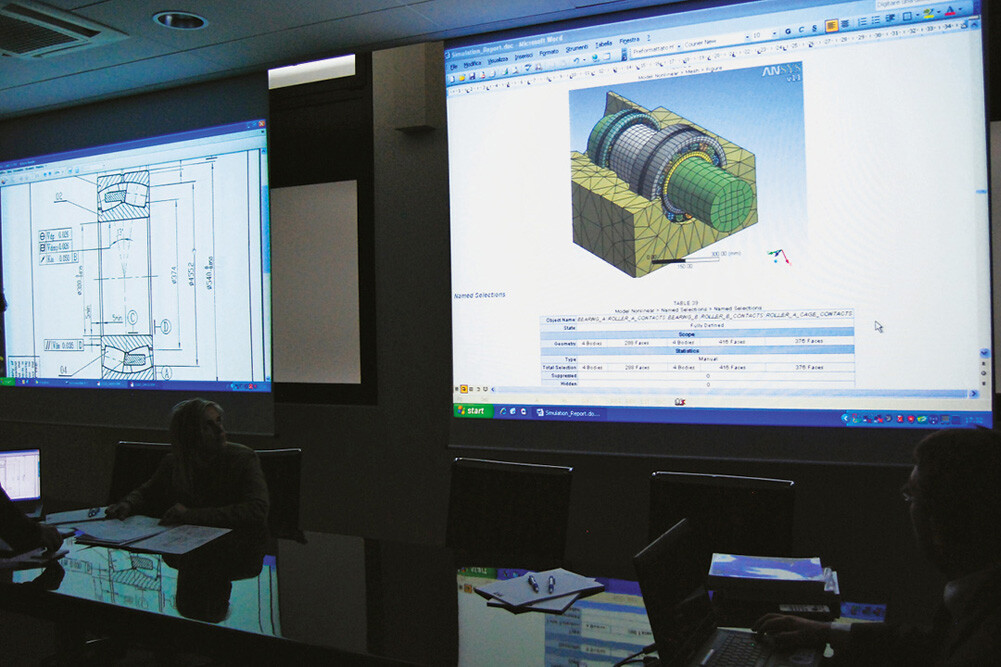

Aubearing has complete solutions and services for bearings required by the railway industry, and has core competitiveness in the design of axle box bearings, motor bearings, and gearbox bearings. From design knowledge, advanced axlebox bearings to verifying reliability and safety requirements, installing bearings, Aubearing improves the safety, reliability and service life of railway vehicles in various fields. Aubearing Test Center can analyze and test all kinds of railway bearings.

Aubearing’s products used in the railway industry include:

Axle box bearing

Motor bearing

Motor Insulated Bearings

Gearbox bearings, etc.

Table of Contents

ToggleRailway Bearings: Why Aubearing?

Innovation: Helping You Profit

Incorporating the latest technological advancements, Aubearing provide the best performance and reliability. We implement solutions designed to reduce the total cost of ownership (TCO) and life cycle cost (LCC) of applications.

Choice: Covers all types of train bearing discounts

Regardless of the train type (high-speed, low-speed, intercity, tram, metro and freight cars), we have a solution for each of your railway applications (bogies, axles, transmission and traction). Our bearings are suitable for railway use around the world and meet the standards of each country.

Every type of manufacturing equipment is different, so finding the right bearing product for your railroad, high-speed train, and other railroad equipment is essential. We can help you manufacture the best bearings for your application so they can operate efficiently and safely. Like passengers, operators and manufacturers of all rail vehicles expect a high level of reliability and operational safety from any type of rail vehicle, from trams to high-speed trains. Taking light rail vehicles as an example, attention is paid to low-floor, multi-group design, and its running gear, bogie and other components must be designed very compactly.

Gearbox bearing

The main functions of rolling bearings in gearboxes are to stabilize the shaft and support the transmission of force. This means extreme loads in complex environments must be withstood. Gearbox bearing types mainly include tapered roller bearings, four-point joint contact bearings, cylindrical roller bearings, deep groove ball bearings, spherical roller bearings, and angular joint contact ball bearings. Bearing arrangements vary; mainly based on gearbox design and operating conditions.

The main requirements for bearings used in gearboxes are:

●High speed

●High load

●Resistant to vibration and shock

●High temperature resistance

●High guiding precision

●Compact design

The characteristics of Aubearing gearbox bearings are:

●Enhanced internal design

●Special cage design

●Reduce tolerance and adjust internal clearance

●The outer ring is designed with a stop groove to prevent it from rotating

Axle box bearing

In freight electric locomotives, the axlebox uses two rolling bearings to support the tractive force of the transverse motor. The hoop bearing directly hangs the traction motor and hangs on the wheel set shaft. To achieve a long service life of the hugging bearings (normally, the service life should exceed 2 million kilometers), the rolling bearings used here should have a very high load carrying capacity.

High loads caused by vibration and shock are commonly used.

Special tapered roller bearings with reinforced stamped metal cages carry the load.

Outer ring with flange or insulation.

Special designs are also available on request.

Traction motor bearings

Traction motors mainly use deep groove ball bearings or cylindrical roller bearings. Classical traction motor bearings consist of fixed and floating bearing arrangements. Bearing positions are divided into output side and fan side or drive end and non-drive end.

Inside the motor, a potential difference develops between the rotor and the stator. To prevent potential compensation through rolling bearings, Aubearing offers insulated bearings with insulating coating up to 3000V DC as well as hybrid ceramic bearings. Hybrid bearings consist of bearing rings made of rolling bearing steel and rolling elements made of ceramics and are divided into deep groove ball bearings and cylindrical roller bearing design types. Especially for AC motors with high frequency control systems, hybrid ceramic bearings are the safest way to prevent damaging currents from flowing inside the bearing.

●Insulated bearing

●Hybrid ceramic bearing

●Special cage design

●Reinforced internal design

●Adjustable tolerance and internal clearance

●Effective ceramic insulation

Wheel Bearing

Wheelset bearings are the defined interface between the wheelset and the bogie and are safety-related components. The most common types of wheel set bearings are cylindrical roller bearings and tapered roller bearings. Commonly used cylindrical roller bearings are standardized in DIN 5412-11. Both types of bearings are factory manufactured to the highest quality class (Class 1) according to EN12080 and are fitted with glass fiber reinforced polyamide cages (suffix TVP) or brass cages. The product range ranges from providing rings adapted to critical conditions and insulating coatings to sealed and lubricated axlebox bearing units. The grease used complies with the EN12081 standard. All wheel set bearings can be delivered according to customer requirements according to EN12082 standard.

Thanks to a close cooperative process between rolling stock manufacturers and operators, Aubearing provides the optimum configuration for each bearing application. Our product range includes axlebox bearings and axlebox housings for traction motors, gearboxes, vehicle linkages and pendulum technology bearings and their parts – door and sliding wall bearings and the entire range. Bearings used in the railway industry must have high load carrying capacity, dynamics and safety performance.