Bearing Manufacturer & Supplier

Specialize in ball bearings, roller bearings, thrust bearings, thin section bearings etc.

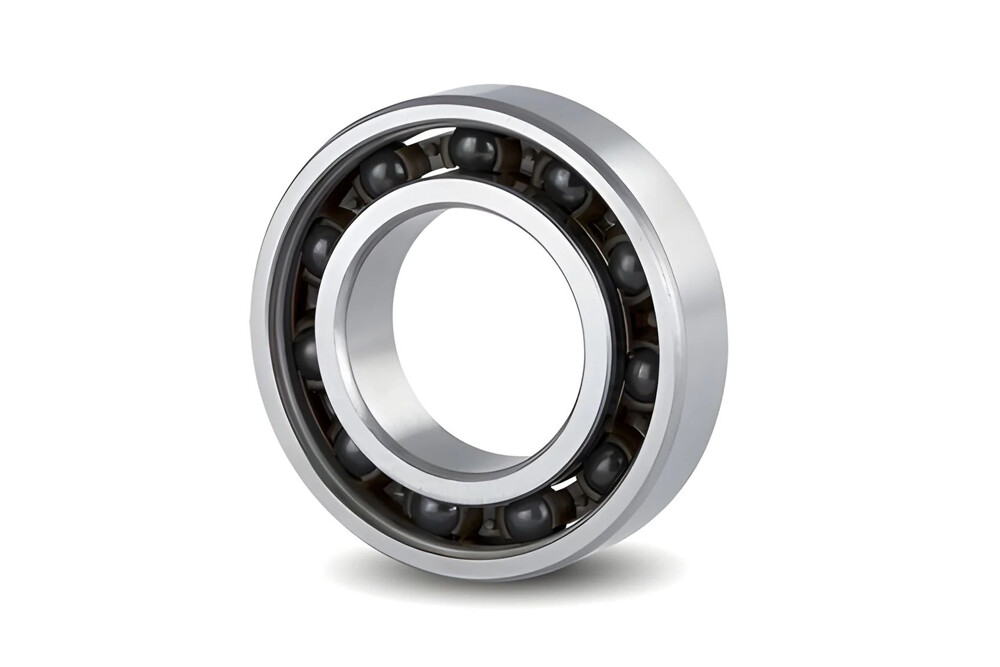

Overview of Hybrid Ceramic Bearings

For special applications, chromium steel bearings and all-ceramic bearings can no longer meet the needs. Chromium steel bearings are cheap, but have poor corrosion resistance; all-ceramic bearings have good corrosion resistance, but have poor impact resistance and are expensive. Under such circumstances, hybrid ceramic bearings are becoming and popular. They have certain corrosion resistance, and most importantly, they also have self-lubricating functions. At the same time, the price is much lower than that of all-ceramic bearings. This blog aims to introduce the advantages, materials, applications of hybrid ceramic bearings and considerations for selecting hybrid ceramic bearings.

Table of Contents

ToggleWhat are hybrid ceramic bearings?

Hybrid ceramic bearing structure: bearing steel ring, or stainless steel ring + ceramic ball + nylon (PEEK) cage + rubber seal. The rolling elements of the bearings are made of ceramic materials instead of metal materials such as chromium steel. The purpose is that ceramics have better wear resistance, corrosion resistance, high temperature resistance, electrical insulation, non-magnetic conductivity, high strength, high stiffness, and small specific gravity than chromium steel. performance. The use of ceramic materials can enable bearings to operate normally in higher rotation speeds, harsher environments and low lubrication situations, and can reduce wear, noise, vibration, and make maintenance relatively easy, thereby achieving a longer service life and significantly improving its performance and reliability.

Advantages of hybrid ceramic bearings

High temperature resistance. The thermal expansion coefficient of ceramic balls is small. In high temperature environments, the bearing balls will not expand excessively due to temperature rise, which greatly increases the operating temperature of the entire bearing. Ordinary bearings can withstand temperatures of around 160 degrees, while hybrid ceramic ball bearings can withstand temperatures of than 220 degrees.

High speed. Hybrid ceramic ball bearings have oil-free self-lubricating properties. Due to the small friction coefficient of ceramic balls, ceramic ball bearings have high rotational speeds. Under the same working conditions, hybrid ceramic ball bearings have a rotational speed than 1.5 times that of chromium steel bearings, and can operate under conditions with a dn value exceeding 3 million.

long life. Chromium steel bearings are used in water and high temperature environments. The grease is easy to wash off or dry out, and it is also easy to be corroded, so the bearings will break down quickly. Using ceramic balls as rolling elements avoids premature bearing damage caused by grease drying out in ordinary bearings; the service life of hybrid ceramic ball bearings is 2-3 times that of ordinary chromium steel bearings. Due to the high elastic modulus of ceramic materials, their rigidity is 15-20% greater than that of ordinary steel bearings.

insulation. The rolling elements use ceramic balls, which can achieve insulation between the inner ring and the outer ring of the bearing. Because the ceramic ball is an insulator, it can achieve an insulation effect. This allows the bearing to be used in a conductive environment. This is also one of the biggest advantages of hybrid ceramic bearings.

Oil-free self-lubricating. Ceramic balls have oil-free self-lubricating properties, which means that even if the grease dries out, the bearing can still work normally. In addition to operating longer under poor lubrication conditions, hybrid ceramic bearings have other properties: Due to their lower density, hybrid ceramic bearings enable higher rotational speeds and lower operating temperatures.

Hybrid ceramic bearing materials

As we mentioned, ceramic bearings have a reputation for being stronger, lighter, and lasting longer than other materials. What are ceramic bearings made of? Commonly used ceramic ball materials include zirconia (ZRO2) and silicon nitride (SI3N4); commonly used ferrule materials include bearing steel (GCR15) and stainless steel (440, 440C) and stainless steel (304, 316, 316L).

Hybrid ceramic ball bearings, especially silicon nitride hybrid ceramic ball bearings, have the characteristics of low density, high hardness, low friction coefficient, antimagnetic electrical insulation, wear resistance, self-lubricating and good rigidity. They have good acid and alkali resistance, self-lubricating function, High temperature resistance of than 300°C, high wear resistance, high speed greatly reduces rolling, friction and heat generation, long service life is 3 to 5 times that of all-steel bearings, lightweight ceramic materials are 60% lighter than steel, and have the same rigidity The elasticity of ceramic materials is 50% higher than that of bearing steel. Due to its superior comprehensive properties, Si3N4 has become the preferred material for rolling elements in hybrid ceramic bearings.

Note: While ceramic bearing material is stronger than steel, it is brittle and susceptible to shock loads, which is why we don’t recommend it for use on off-road bikes.

Applications of hybrid ceramic bearings

High-speed application. It is generally believed that steel bearings can meet the requirements when the bearing dm·n value is lower than 2×106mm.r.min-1 and the outer ring contact force should be lower than 2000MPa. However, when the dm·n value of the bearing is required to be higher, especially when the contact stress of the bearing outer ring is higher than 2000MPa, only ceramic ball bearings can meet the extremely high speed requirements.

CNC machine tool spindle. CNC machining centers are required to be high-speed in order to improve processing efficiency and processing accuracy. The rotational speed characteristic value of hybrid ceramic ball bearings dm·n value can reach than 2×106mm.r.min-1, and can reach 1×106mm.r under grease lubrication conditions. .min-1 and the friction characteristics, temperature rise characteristics, stiffness, etc. have been greatly improved, and it is widely used in CNC machine tool spindles.

Automotive. The automotive bearing that has the highest speed requirements is the turbine motor, which requires the bearing to have good acceleration response, as well as low torque, low vibration and low temperature requirements under high-speed rotation. Since the temperature rise of hybrid ceramic ball bearings is low during operation, the amount of lubricating oil can be reduced, so the stirring resistance of the oil is reduced. In addition, hybrid ceramic ball bearings have proven durability and reliability under harsh conditions.

Insulation and magnetic environment. Taking advantage of the insulating and non-magnetic properties of ceramics, ceramic bearings are used in situations where there is electrical corrosion such as motors and generators, as well as in situations where magnetism exists and good rotation of the bearing is required. Such as electric locomotives, wind power equipment, medical equipment, etc.

Corrosive environment. Taking advantage of the good corrosion resistance properties of stainless steel and ceramics, hybrid ceramic ball bearings can be used in a variety of corrosive environments. Such as chemical equipment, food processing equipment, bicycles and other outdoor sports equipment, etc.

Extreme temperature environment. Hybrid ceramic bearings can enable the bearings to work at 200℃~400℃ for a long time. At the same time, it can also be used in low-temperature environments and works stably below -180°C, such as liquid oxygen pump bearings.

Aviation and aerospace fields. As countries develop their aerospace vehicles in a cutting-edge direction, the working conditions of aerospace vehicles are becoming and demanding. In some cases, metal materials can no longer meet the requirements or can even be used. Countries have increasingly adopted hybrid ceramic ball bearings in the aerospace field. , for example, aircraft manufacturers have used ball screws equipped with ceramic balls for aircraft flap adjusters.

How to choose hybrid ceramic ball bearings

Choosing the right ceramic bearing requires consideration of many factors, including material, size, accuracy, speed, load and load capacity, working environment factors, and cost. Based on the actual application scenarios and needs, comprehensively weighing these factors and selecting a suitable hybrid ceramic ball bearing can give full play to its excellent performance and improve the working efficiency and service life of mechanical equipment.

Materials: Hybrid ceramic ball bearings are available in a variety of material types, such as aluminum oxide, silicon nitride, silicon carbide, etc. Each material type has its own unique properties and applicability. For example, alumina ceramic bearings have good corrosion resistance and are suitable for the chemical and food processing industries; while silicon nitride ceramic bearings have high thermal conductivity and low thermal expansion coefficient and are suitable for high temperature and high-speed environments.

Dimensions and Accuracy: The dimensions and accuracy of ceramic bearings have a significant impact on their performance and service life. Selecting the appropriate size and accuracy grade to ensure the match between the bearing and the mechanical device is a key factor in selecting ceramic bearings.

load capacity: Select the appropriate ceramic bearing according to the load and load capacity in the actual application to ensure that the bearing can withstand sufficient load while maintaining good operating performance.

Speed: Speed has a direct impact on the performance and service life of ceramic bearings. Choose ceramic bearings suitable for the rotation speed to ensure good stability and low friction coefficient at high rotation speeds.

Cost: Ceramic bearings are expensive than chromium steel bearings, so the relationship between performance and cost needs to be weighed when choosing to ensure economic rationality.

Working environment: Consider the usage environment of ceramic bearings, such as temperature, humidity, corrosion, etc. Select the ceramic bearing material and seal type appropriate for your specific environment to extend the life of your bearings.

Finding a trustworthy bearing supplier is crucial. Ensure that the quality of the bearings meets the requirements to ensure the safety and efficiency of bearing manufacturing. You can contact the bearing supplier to seek samples and technical specifications. After confirming that it is suitable for your application needs, you can ask the high-quality bearing manufacturer to conduct a full-scale inspection of the bearing before shipment and obtain a quality inspection report to ensure that the bearing reliability. At the same time, you can also ask some bearing manufacturers that you have cooperated with to learn about their experience and opinions.