Bearing Manufacturer & Supplier

Specialize in ball bearings, roller bearings, thrust bearings, thin section bearings etc.

Guide to Crossed Roller Bearing Dimensions

As a high-performance mechanical component, crossed roller bearings play a vital role in modern industry due to their unique structural design and excellent performance. Their applications cover a wide range of fields from high-precision machine tools to aerospace equipment. This article will delve into the advantages, types, dimension tables, applications, selection methods, as well as conclusions and FAQs of crossed roller bearings to help you fully understand this key component.

Table of Contents

ToggleAdvantages of Crossed Roller Bearings

Crossed roller bearings have many advantages in high-precision and high-load applications, mainly including the following aspects:

High Precision

Crossed roller bearings are manufactured with extremely high precision, and the clearance between their rolling elements is strictly controlled, ensuring that the bearings have high rotational accuracy during operation. This high-precision feature makes crossed roller bearings particularly good in applications that require high-precision positioning and rotational motion, such as CNC machine tools and optical instruments.

Good High-Speed Performance

Due to the optimization of the structural design, crossed roller bearings can also maintain good performance when running at high speeds. Its rolling elements have low friction and low temperature rise during operation, and can work stably in high-speed rotating equipment, such as centrifuges and turbomachinery.

High Rigidity

The rolling elements of crossed roller bearings are arranged linearly, and this design makes the bearings very rigid. It can remain stable under high loads and prevent deformation, thereby ensuring high precision and stability of the equipment.

Strong Load Capacity

Cross roller bearings can simultaneously withstand multi-directional loads such as radial, axial and overturning moments. This versatile load capacity enables it to maintain good performance under complex load conditions.

Compact design Crossed roller bearings have a compact design that provides the same or even higher performance in a smaller space than conventional bearings. This makes them particularly suitable for applications that require space and weight savings, such as robotic joints and aerospace equipment.

Types and size tables of crossed roller bearings

Depending on their structure and rolling elements, crossed roller bearings are mainly divided into crossed cylindrical roller bearings and crossed tapered roller bearings. The following is a detailed introduction to these two types:

Cross cylindrical roller bearing size chart

The rolling elements of cross cylindrical roller bearings are cylindrical rollers arranged in a 90° cross state, which can simultaneously withstand radial, axial and overturning moments. According to the specific design and use, cross cylindrical roller bearings can be further divided into the following types:

RB type size chart

RB type cross roller bearings are basic types, with an outer ring divided into two pieces and an inner ring of an integral structure, suitable for occasions requiring high inner ring rotation accuracy. This bearing has a compact structure and can provide high rigidity and high precision.

| Part Number | Seal Type | Bore Dia | Outer Dia | Width | Shoulder Height Ds(max) | Ring Material | Roller Material | Weight |

| RB1000110 | Open | 1000 mm | 1250 mm | 110 mm | 1057 mm | Steel | Steel | 360 Kg |

| RB1000110UU | Open | 1000 mm | 1250 mm | 110 mm | 1057 mm | Steel | Steel | 360 Kg |

| RB10016 | Open | 100 mm | 140 mm | 16 mm | 109 mm | Steel | Steel | 0.83 Kg |

| RB10016UU | Sealed | 100 mm | 140 mm | 16 mm | 109 mm | Steel | Steel | 0.83 Kg |

| RB10020 | Open | 100 mm | 150 mm | 20 mm | 113 mm | Steel | Steel | 1.45 Kg |

| RB10020UU | Sealed | 100 mm | 150 mm | 20 mm | 113 mm | Steel | Steel | 1.45 Kg |

| RB11012 | Open | 110 mm | 135 mm | 12 mm | 117 mm | Steel | Steel | 0.4 Kg |

| RB11012UU | Sealed | 110 mm | 135 mm | 12 mm | 117 mm | Steel | Steel | 0.4 Kg |

| RB11015 | Open | 110 mm | 145 mm | 15 mm | 119 mm | Steel | Steel | 0.75 Kg |

| RB11015UU | Sealed | 110 mm | 145 mm | 15 mm | 119 mm | Steel | Steel | 0.75 Kg |

| RB11020 | Open | 110 mm | 160 mm | 20 mm | 120 mm | Steel | Steel | 1.56 Kg |

| RB11020UU | Sealed | 110 mm | 160 mm | 20 mm | 120 mm | Steel | Steel | 1.56 Kg |

| RB12016 | Open | 120 mm | 150 mm | 16 mm | 127 mm | Steel | Steel | 0.72 Kg |

| RB12016UU | Sealed | 120 mm | 150 mm | 16 mm | 127 mm | Steel | Steel | 0.72 Kg |

| RB12025 | Open | 120 mm | 180 mm | 25 mm | 133 mm | Steel | Steel | 2.62 Kg |

| RB12025UU | Sealed | 120 mm | 180 mm | 25 mm | 133 mm | Steel | Steel | 2.62 Kg |

| RB1250110 | Open | 1250 mm | 1500 mm | 110 mm | 1308 mm | Steel | Steel | 440 Kg |

| RB1250110UU | Open | 1250 mm | 1500 mm | 110 mm | 1308 mm | Steel | Steel | 440 Kg |

| RB13015 | Open | 130 mm | 160 mm | 15 mm | 137 mm | Steel | Steel | 0.72 Kg |

| RB13015UU | Sealed | 130 mm | 160 mm | 15 mm | 137 mm | Steel | Steel | 0.72 Kg |

| RB13025 | Open | 130 mm | 190 mm | 25 mm | 143 mm | Steel | Steel | 2.82 Kg |

| RB13025UU | Sealed | 130 mm | 190 mm | 25 mm | 143 mm | Steel | Steel | 2.82 Kg |

| RB14016 | Open | 140 mm | 175 mm | 16 mm | 147 mm | Steel | Steel | 1 Kg |

| RB14016UU | Sealed | 140 mm | 175 mm | 16 mm | 147 mm | Steel | Steel | 1 Kg |

| RB14025 | Open | 140 mm | 200 mm | 25 mm | 154 mm | Steel | Steel | 2.96 Kg |

| RB14025UU | Sealed | 140 mm | 200 mm | 25 mm | 154 mm | Steel | Steel | 2.96 Kg |

| RB15013 | Open | 150 mm | 180 mm | 13 mm | 157 mm | Steel | Steel | 0.68 Kg |

| RB15013UU | Sealed | 150 mm | 180 mm | 13 mm | 157 mm | Steel | Steel | 0.68 Kg |

| RB15025 | Open | 150 mm | 210 mm | 25 mm | 164 mm | Steel | Steel | 3.16 Kg |

| RB15025UU | Sealed | 150 mm | 210 mm | 25 mm | 164 mm | Steel | Steel | 3.16 Kg |

| RB15030 | Open | 150 mm | 230 mm | 30 mm | 169 mm | Steel | Steel | 5.3 Kg |

| RB15030UU | Sealed | 150 mm | 230 mm | 30 mm | 169 mm | Steel | Steel | 5.3 Kg |

| RB16025 | Open | 160 mm | 220 mm | 25 mm | 173 mm | Steel | Steel | 3.14 Kg |

| RB16025UU | Sealed | 160 mm | 220 mm | 25 mm | 173 mm | Steel | Steel | 3.14 Kg |

| RB17020 | Open | 170 mm | 220 mm | 20 mm | 184 mm | Steel | Steel | 2.21 Kg |

| RB17020UU | Sealed | 170 mm | 220 mm | 20 mm | 184 mm | Steel | Steel | 2.21 Kg |

| RB18025 | Open | 180 mm | 240 mm | 25 mm | 195 mm | Steel | Steel | 3.44 Kg |

| RB18025UU | Sealed | 180 mm | 240 mm | 25 mm | 195 mm | Steel | Steel | 3.44 Kg |

| RB19025 | Open | 190 mm | 240 mm | 25 mm | 202 mm | Steel | Steel | 2.99 Kg |

| RB19025UU | Sealed | 190 mm | 240 mm | 25 mm | 202 mm | Steel | Steel | 2.99 Kg |

| RB20025 | Open | 200 mm | 260 mm | 25 mm | 215 mm | Steel | Steel | 4 Kg |

| RB20025UU | Sealed | 200 mm | 260 mm | 25 mm | 215 mm | Steel | Steel | 4 Kg |

| RB20030 | Open | 200 mm | 280 mm | 30 mm | 221 mm | Steel | Steel | 6.7 Kg |

| RB20035 | Open | 200 mm | 295 mm | 35 mm | 225 mm | Steel | Steel | 9.6 Kg |

| RB2008 | Open | 20 mm | 36 mm | 8 mm | 23.5 mm | Steel | Steel | 0.04 Kg |

| RB2008UU | Sealed | 20 mm | 36 mm | 8 mm | 23.5 mm | Steel | Steel | 0.04 Kg |

| RB22025 | Open | 220 mm | 280 mm | 25 mm | 235 mm | Steel | Steel | 4.1 Kg |

| RB22025UU | Sealed | 220 mm | 280 mm | 25 mm | 235 mm | Steel | Steel | 4.1 Kg |

| RB24025 | Open | 240 mm | 300 mm | 25 mm | 256 mm | Steel | Steel | 4.5 Kg |

| RB24025UU | Sealed | 240 mm | 300 mm | 25 mm | 256 mm | Steel | Steel | 4.5 Kg |

| RB25025 | Open | 250 mm | 310 mm | 25 mm | 265 mm | Steel | Steel | 5 Kg |

| RB25025UU | Sealed | 250 mm | 310 mm | 25 mm | 265 mm | Steel | Steel | 5 Kg |

| RB25030 | Open | 250 mm | 330 mm | 30 mm | 269 mm | Steel | Steel | 8.1 Kg |

| RB25040 | Open | 250 mm | 355 mm | 40 mm | 275 mm | Steel | Steel | 14.8 Kg |

| RB2508 | Open | 25 mm | 41 mm | 8 mm | 28.5 mm | Steel | Steel | 0.05 Kg |

| RB2508UU | Sealed | 25 mm | 41 mm | 8 mm | 28.5 mm | Steel | Steel | 0.05 Kg |

| RB30025 | Open | 300 mm | 360 mm | 25 mm | 315 mm | Steel | Steel | 5.9 Kg |

| RB30025UU | Sealed | 300 mm | 360 mm | 25 mm | 315 mm | Steel | Steel | 5.9 Kg |

| RB30035 | Open | 300 mm | 395 mm | 35 mm | 322 mm | Steel | Steel | 13.4 Kg |

| RB30040 | Open | 300 mm | 405 mm | 40 mm | 326 mm | Steel | Steel | 17.2 Kg |

| RB3010 | Open | 30 mm | 55 mm | 10 mm | 37 mm | Steel | Steel | 0.12 Kg |

| RB3010UU | Sealed | 30 mm | 55 mm | 10 mm | 37 mm | Steel | Steel | 0.12 Kg |

| RB35020 | Open | 350 mm | 400 mm | 20 mm | 363 mm | Steel | Steel | 3.9 Kg |

| RB35020UU | Sealed | 350 mm | 400 mm | 20 mm | 363 mm | Steel | Steel | 3.9 Kg |

| RB3510 | Open | 35 mm | 60 mm | 10 mm | 41 mm | Steel | Steel | 0.13 Kg |

| RB3510UU | Sealed | 35 mm | 60 mm | 10 mm | 41 mm | Steel | Steel | 0.13 Kg |

| RB40035 | Open | 400 mm | 480 mm | 35 mm | 422 mm | Steel | Steel | 14.5 Kg |

| RB40040 | Open | 400 mm | 510 mm | 40 mm | 428 mm | Steel | Steel | 23.5 Kg |

| RB4010 | Open | 40 mm | 65 mm | 10 mm | 46.5 mm | Steel | Steel | 0.16 Kg |

| RB4010UU | Sealed | 40 mm | 65 mm | 10 mm | 46.5 mm | Steel | Steel | 0.16 Kg |

| RB45025 | Open | 450 mm | 500 mm | 25 mm | 464 mm | Steel | Steel | 6.6 Kg |

| RB45025UU | Sealed | 450 mm | 500 mm | 25 mm | 464 mm | Steel | Steel | 6.6 Kg |

| RB4510 | Open | 45 mm | 70 mm | 10 mm | 51 mm | Steel | Steel | 0.17 Kg |

| RB4510UU | Sealed | 45 mm | 70 mm | 10 mm | 51 mm | Steel | Steel | 0.17 Kg |

| RB50025 | Open | 500 mm | 550 mm | 25 mm | 514 mm | Steel | Steel | 7.3 Kg |

| RB50025UU | Sealed | 500 mm | 550 mm | 25 mm | 514 mm | Steel | Steel | 7.3 Kg |

| RB50040 | Open | 500 mm | 600 mm | 40 mm | 526 mm | Steel | Steel | 26 Kg |

| RB50040UU | Sealed | 500 mm | 600 mm | 40 mm | 526 mm | Steel | Steel | 26 Kg |

| RB50050 | Open | 500 mm | 625 mm | 50 mm | 536 mm | Steel | Steel | 41.7 Kg |

| RB50050UU | Sealed | 500 mm | 625 mm | 50 mm | 536 mm | Steel | Steel | 41.7 Kg |

| RB5013 | Open | 50 mm | 80 mm | 13 mm | 57 mm | Steel | Steel | 0.27 Kg |

| RB5013UU | Sealed | 50 mm | 80 mm | 13 mm | 57 mm | Steel | Steel | 0.27 Kg |

| RB60040 | Open | 600 mm | 700 mm | 40 mm | 627 mm | Steel | Steel | 29 Kg |

| RB6013 | Open | 60 mm | 90 mm | 13 mm | 67 mm | Steel | Steel | 0.3 Kg |

| RB6013UU | Sealed | 60 mm | 90 mm | 13 mm | 67 mm | Steel | Steel | 0.3 Kg |

| RB70045 | Open | 700 mm | 815 mm | 45 mm | 731 mm | Steel | Steel | 46 Kg |

| RB7013 | Open | 70 mm | 100 mm | 13 mm | 77 mm | Steel | Steel | 0.35 Kg |

| RB7013UU | Sealed | 70 mm | 100 mm | 13 mm | 77 mm | Steel | Steel | 0.35 Kg |

| RB80070 | Open | 800 mm | 950 mm | 70 mm | 836 mm | Steel | Steel | 105 Kg |

| RB8016 | Open | 80 mm | 120 mm | 16 mm | 88 mm | Steel | Steel | 0.7 Kg |

| RB8016UU | Sealed | 80 mm | 120 mm | 16 mm | 88 mm | Steel | Steel | 0.7 Kg |

| RB90070 | Open | 900 mm | 1050 mm | 70 mm | 937 mm | Steel | Steel | 120 Kg |

| RB90070UU | Open | 900 mm | 1050 mm | 70 mm | 937 mm | Steel | Steel | 120 Kg |

| RB9016 | Open | 90 mm | 130 mm | 16 mm | 98 mm | Steel | Steel | 0.75 Kg |

| RB9016UU | Sealed | 90 mm | 130 mm | 16 mm | 98 mm | Steel | Steel | 0.75 Kg |

RE type size chart

RE type cross roller bearings are similar to RB type, but the outer ring is an integral structure and the inner ring is divided into two pieces. Its design is suitable for applications requiring high outer ring rotation accuracy and has high stability and rigidity.

| Part Number | Seal Type | Bore Dia | Outer Dia | Width | Ring Material | Roller Material | Temperature Range | Weight |

| RE10016 | Open | 100 mm | 140 mm | 16 mm | Steel | Steel | 0 -230 掳F | 0.83 Kg |

| RE10016UU | Sealed | 100 mm | 140 mm | 16 mm | Steel | Steel | 0 -230 掳F | 0.83 Kg |

| RE10020 | Open | 100 mm | 150 mm | 20 mm | Steel | Steel | 0 -230 掳F | 1.45 Kg |

| RE10020UU | Sealed | 100 mm | 150 mm | 20 mm | Steel | Steel | 0 -230 掳F | 1.45 Kg |

| RE11012 | Open | 110 mm | 135 mm | 12 mm | Steel | Steel | 0 -230 掳F | 0.4 Kg |

| RE11012UU | Sealed | 110 mm | 135 mm | 12 mm | Steel | Steel | 0 -230 掳F | 0.4 Kg |

| RE11015 | Open | 110 mm | 145 mm | 15 mm | Steel | Steel | 0 -230 掳F | 0.75 Kg |

| RE11015UU | Sealed | 110 mm | 145 mm | 15 mm | Steel | Steel | 0 -230 掳F | 0.75 Kg |

| RE11020 | Open | 110 mm | 160 mm | 20 mm | Steel | Steel | 0 -230 掳F | 1.56 Kg |

| RE11020UU | Sealed | 110 mm | 160 mm | 20 mm | Steel | Steel | 0 -230 掳F | 1.56 Kg |

| RE12016 | Open | 120 mm | 150 mm | 16 mm | Steel | Steel | 0 -230 掳F | 0.72 Kg |

| RE12016UU | Sealed | 120 mm | 150 mm | 16 mm | Steel | Steel | 0 -230 掳F | 0.72 Kg |

| RE12025 | Open | 120 mm | 180 mm | 25 mm | Steel | Steel | 0 -230 掳F | 2.62 Kg |

| RE12025UU | Sealed | 120 mm | 180 mm | 25 mm | Steel | Steel | 0 -230 掳F | 2.62 Kg |

| RE13015 | Open | 130 mm | 160 mm | 15 mm | Steel | Steel | 0 -230 掳F | 0.72 Kg |

| RE13015UU | Sealed | 130 mm | 160 mm | 15 mm | Steel | Steel | 0 -230 掳F | 0.72 Kg |

| RE13025 | Open | 130 mm | 190 mm | 25 mm | Steel | Steel | 0 -230 掳F | 2.82 Kg |

| RE13025UU | Sealed | 130 mm | 190 mm | 25 mm | Steel | Steel | 0 -230 掳F | 2.82 Kg |

| RE14016 | Open | 140 mm | 175 mm | 16 mm | Steel | Steel | 0 -230 掳F | 1 Kg |

| RE14016UU | Sealed | 140 mm | 175 mm | 16 mm | Steel | Steel | 0 -230 掳F | 1 Kg |

| RE14025 | Open | 140 mm | 200 mm | 25 mm | Steel | Steel | 0 -230 掳F | 2.96 Kg |

| RE14025UU | Sealed | 140 mm | 200 mm | 25 mm | Steel | Steel | 0 -230 掳F | 2.96 Kg |

| RE15013 | Open | 150 mm | 180 mm | 13 mm | Steel | Steel | 0 -230 掳F | 0.68 Kg |

| RE15013UU | Sealed | 150 mm | 180 mm | 13 mm | Steel | Steel | 0 -230 掳F | 0.68 Kg |

| RE15025 | Open | 150 mm | 210 mm | 25 mm | Steel | Steel | 0 -230 掳F | 3.16 Kg |

| RE15025UU | Sealed | 150 mm | 210 mm | 25 mm | Steel | Steel | 0 -230 掳F | 3.16 Kg |

| RE15030 | Open | 150 mm | 230 mm | 30 mm | Steel | Steel | 0 -230 掳F | 5.3 Kg |

| RE15030UU | Sealed | 150 mm | 230 mm | 30 mm | Steel | Steel | 0 -230 掳F | 5.3 Kg |

| RE16025 | Open | 160 mm | 220 mm | 25 mm | Steel | Steel | 0 -230 掳F | 3.14 Kg |

| RE16025UU | Sealed | 160 mm | 220 mm | 25 mm | Steel | Steel | 0 -230 掳F | 3.14 Kg |

| RE17020 | Open | 170 mm | 220 mm | 20 mm | Steel | Steel | 0 -230 掳F | 2.21 Kg |

| RE17020UU | Sealed | 170 mm | 220 mm | 20 mm | Steel | Steel | 0 -230 掳F | 2.21 Kg |

| RE18025 | Open | 180 mm | 240 mm | 25 mm | Steel | Steel | 0 -230 掳F | 3.44 Kg |

| RE18025UU | Sealed | 180 mm | 240 mm | 25 mm | Steel | Steel | 0 -230 掳F | 3.44 Kg |

| RE19025 | Open | 190 mm | 240 mm | 25 mm | Steel | Steel | 0 -230 掳F | 2.99 Kg |

| RE19025UU | Sealed | 190 mm | 240 mm | 25 mm | Steel | Steel | 0 -230 掳F | 2.99 Kg |

| RE20025 | Open | 200 mm | 260 mm | 25 mm | Steel | Steel | 0 -230 掳F | 4 Kg |

| RE20025UU | Sealed | 200 mm | 260 mm | 25 mm | Steel | Steel | 0 -230 掳F | 4 Kg |

| RE20030 | Open | 200 mm | 280 mm | 30 mm | Steel | Steel | 0 -230 掳F | 6.7 Kg |

| RE20030UU | Sealed | 200 mm | 280 mm | 30 mm | Steel | Steel | 0 -230 掳F | 6.7 Kg |

| RE20035 | Open | 200 mm | 295 mm | 35 mm | Steel | Steel | 0 -230 掳F | 9.6 Kg |

| RE20035UU | Sealed | 200 mm | 295 mm | 35 mm | Steel | Steel | 0 -230 掳F | 9.6 Kg |

| RE2008 | Open | 20 mm | 36 mm | 8 mm | Steel | Steel | 0 -230 掳F | 0.04 Kg |

| RE2008UU | Sealed | 20 mm | 36 mm | 8 mm | Steel | Steel | 0 -230 掳F | 0.04 Kg |

| RE22025 | Open | 220 mm | 280 mm | 25 mm | Steel | Steel | 0 -230 掳F | 4.1 Kg |

| RE22025UU | Sealed | 220 mm | 280 mm | 25 mm | Steel | Steel | 0 -230 掳F | 4.1 Kg |

| RE24025 | Open | 240 mm | 300 mm | 25 mm | Steel | Steel | 0 -230 掳F | 4.5 Kg |

| RE24025UU | Sealed | 240 mm | 300 mm | 25 mm | Steel | Steel | 0 -230 掳F | 4.5 Kg |

| RE25025 | Open | 250 mm | 310 mm | 25 mm | Steel | Steel | 0 -230 掳F | 5 Kg |

| RE25025UU | Sealed | 250 mm | 310 mm | 25 mm | Steel | Steel | 0 -230 掳F | 5 Kg |

| RE25030 | Open | 250 mm | 330 mm | 30 mm | Steel | Steel | 0 -230 掳F | 8.1 Kg |

| RE25030UU | Sealed | 250 mm | 330 mm | 30 mm | Steel | Steel | 0 -230 掳F | 8.1 Kg |

| RE25040 | Open | 250 mm | 355 mm | 40 mm | Steel | Steel | 0 -230 掳F | 14.8 Kg |

| RE25040UU | Sealed | 250 mm | 355 mm | 40 mm | Steel | Steel | 0 -230 掳F | 14.8 Kg |

| RE2508 | Open | 25 mm | 41 mm | 8 mm | Steel | Steel | 0 -230 掳F | 0.05 Kg |

| RE2508UU | Sealed | 25 mm | 41 mm | 8 mm | Steel | Steel | 0 -230 掳F | 0.05 Kg |

| RE30025 | Open | 300 mm | 360 mm | 25 mm | Steel | Steel | 0 -230 掳F | 5.9 Kg |

| RE30025UU | Sealed | 300 mm | 360 mm | 25 mm | Steel | Steel | 0 -230 掳F | 5.9 Kg |

| RE30035 | Open | 300 mm | 395 mm | 35 mm | Steel | Steel | 0 -230 掳F | 13.4 Kg |

| RE30035UU | Sealed | 300 mm | 395 mm | 35 mm | Steel | Steel | 0 -230 掳F | 13.4 Kg |

| RE30040 | Open | 300 mm | 405 mm | 40 mm | Steel | Steel | 0 -230 掳F | 17.2 Kg |

| RE30040UU | Sealed | 300 mm | 405 mm | 40 mm | Steel | Steel | 0 -230 掳F | 17.2 Kg |

| RE3010 | Open | 30 mm | 55 mm | 10 mm | Steel | Steel | 0 -230 掳F | 0.12 Kg |

| RE3010UU | Sealed | 30 mm | 55 mm | 10 mm | Steel | Steel | 0 -230 掳F | 0.12 Kg |

| RE35020 | Open | 350 mm | 400 mm | 20 mm | Steel | Steel | 0 -230 掳F | 3.9 Kg |

| RE35020UU | Sealed | 350 mm | 400 mm | 20 mm | Steel | Steel | 0 -230 掳F | 3.9 Kg |

| RE3510 | Open | 35 mm | 60 mm | 10 mm | Steel | Steel | 0 -230 掳F | 0.13 Kg |

| RE3510UU | Sealed | 35 mm | 60 mm | 10 mm | Steel | Steel | 0 -230 掳F | 0.13 Kg |

| RE40035 | Open | 400 mm | 480 mm | 35 mm | Steel | Steel | 0 -230 掳F | 14.5 Kg |

| RE40035UU | Sealed | 400 mm | 480 mm | 35 mm | Steel | Steel | 0 -230 掳F | 14.5 Kg |

| RE40040 | Open | 400 mm | 510 mm | 40 mm | Steel | Steel | 0 -230 掳F | 23.5 Kg |

| RE40040UU | Sealed | 400 mm | 510 mm | 40 mm | Steel | Steel | 0 -230 掳F | 23.5 Kg |

| RE4010 | Open | 40 mm | 65 mm | 10 mm | Steel | Steel | 0 -230 掳F | 0.16 Kg |

| RE4010UU | Sealed | 40 mm | 65 mm | 10 mm | Steel | Steel | 0 -230 掳F | 0.16 Kg |

| RE45025 | Open | 450 mm | 500 mm | 25 mm | Steel | Steel | 0 -230 掳F | 6.6 Kg |

| RE45025UU | Sealed | 450 mm | 500 mm | 25 mm | Steel | Steel | 0 -230 掳F | 6.6 Kg |

| RE4510 | Open | 45 mm | 70 mm | 10 mm | Steel | Steel | 0 -230 掳F | 0.17 Kg |

| RE4510UU | Sealed | 45 mm | 70 mm | 10 mm | Steel | Steel | 0 -230 掳F | 0.17 Kg |

| RE50025 | Open | 500 mm | 550 mm | 25 mm | Steel | Steel | 0 -230 掳F | 7.3 Kg |

| RE50025UU | Sealed | 500 mm | 550 mm | 25 mm | Steel | Steel | 0 -230 掳F | 7.3 Kg |

| RE50040 | Open | 500 mm | 600 mm | 40 mm | Steel | Steel | 0 -230 掳F | 26 Kg |

| RE50040UU | Sealed | 500 mm | 600 mm | 40 mm | Steel | Steel | 0 -230 掳F | 26 Kg |

| RE50050 | Open | 500 mm | 625 mm | 50 mm | Steel | Steel | 0 -230 掳F | 41.7 Kg |

| RE50050UU | Sealed | 500 mm | 625 mm | 50 mm | Steel | Steel | 0 -230 掳F | 41.7 Kg |

| RE5013 | Open | 50 mm | 80 mm | 13 mm | Steel | Steel | 0 -230 掳F | 0.27 Kg |

| RE5013UU | Sealed | 50 mm | 80 mm | 13 mm | Steel | Steel | 0 -230 掳F | 0.27 Kg |

| RE60040 | Open | 600 mm | 700 mm | 40 mm | Steel | Steel | 0 -230 掳F | 29 Kg |

| RE60040UU | Sealed | 600 mm | 700 mm | 40 mm | Steel | Steel | 0 -230 掳F | 29 Kg |

| RE6013 | Open | 60 mm | 90 mm | 13 mm | Steel | Steel | 0 -230 掳F | 0.3 Kg |

| RE6013UU | Sealed | 60 mm | 90 mm | 13 mm | Steel | Steel | 0 -230 掳F | 0.3 Kg |

| RE7013 | Open | 70 mm | 100 mm | 13 mm | Steel | Steel | 0 -230 掳F | 0.35 Kg |

| RE7013UU | Sealed | 70 mm | 100 mm | 13 mm | Steel | Steel | 0 -230 掳F | 0.35 Kg |

| RE8016 | Open | 80 mm | 120 mm | 16 mm | Steel | Steel | 0 -230 掳F | 0.7 Kg |

| RE8016UU | Sealed | 80 mm | 120 mm | 16 mm | Steel | Steel | 0 -230 掳F | 0.7 Kg |

| RE9016 | Open | 90 mm | 130 mm | 16 mm | Steel | Steel | 0 -230 掳F | 0.75 Kg |

| RE9016UU | Sealed | 90 mm | 130 mm | 16 mm | Steel | Steel | 0 -230 掳F | 0.75 Kg |

RU type size chart

RU type cross roller bearings have both inner and outer rings of an integral structure and have mounting holes, and do not require additional fixing flanges and support seats. Its integral structural design makes installation simple and is suitable for applications where high rotation accuracy is required for inner and outer ring rotation.

| Part Number | Seal Type | Bore Dia | Outer Dia | Width | Ring Material | Weight |

| RU124 | Open | 80 mm | 165 mm | 22 mm | Steel | 2.6 Kg |

| RU124UU | Sealed | 80 mm | 165 mm | 22 mm | Steel | 2.6 Kg |

| RU148 | Open | 90 mm | 210 mm | 25 mm | Steel | 4.9 Kg |

| RU148UU | Sealed | 90 mm | 210 mm | 25 mm | Steel | 4.9 Kg |

| RU178 | Open | 115 mm | 240 mm | 28 mm | Steel | 6.8 Kg |

| RU178UU | Sealed | 115 mm | 240 mm | 28 mm | Steel | 6.8 Kg |

| RU228 | Open | 160 mm | 295 mm | 35 mm | Steel | 11.4 Kg |

| RU228UU | Sealed | 160 mm | 295 mm | 35 mm | Steel | 11.4 Kg |

| RU297 | Open | 210 mm | 380 mm | 40 mm | Steel | 21.3 Kg |

| RU297UU | Sealed | 210 mm | 380 mm | 40 mm | Steel | 21.3 Kg |

| RU42 | Open | 20 mm | 70 mm | 12 mm | Steel | 0.29 Kg |

| RU42UU | Sealed | 20 mm | 70 mm | 12 mm | Steel | 0.31 Kg |

| RU445 | Open | 350 mm | 540 mm | 45 mm | Steel | 35.4 Kg |

| RU445UU | Sealed | 350 mm | 540 mm | 45 mm | Steel | 35.4 Kg |

| RU66 | Open | 35 mm | 95 mm | 15 mm | Steel | 0.62 Kg |

| RU66UU | Sealed | 35 mm | 95 mm | 15 mm | Steel | 0.62 Kg |

| RU85 | Open | 55 mm | 120 mm | 15 mm | Steel | 1 Kg |

| RU85UU | Sealed | 55 mm | 120 mm | 15 mm | Steel | 1 Kg |

SX type dimension table

SX type cross roller bearing has an integral inner ring and a split outer ring, and adopts an ultra-thin design, which is suitable for applications where the inner ring rotates. Its cross-sectional dimensions are smaller than those of RB type, which is very suitable for applications that require miniaturization.

| Part Number | Bore Dia | Outer Dia | Width | Height(H) | Running Accuracy Radial | Weight |

| SX0118/500 | 500 mm | 620 mm | 56 mm | 56 mm | 0.04 mm | 42.7 Kg |

| SX011814-A | 70 mm | 90 mm | 10 mm | 10 mm | 0.01 mm | 0.25 Kg |

| SX011818-A | 90 mm | 115 mm | 13 mm | 13 mm | 0.01 mm | 0.354 Kg |

| SX011820-A | 100 mm | 125 mm | 13 mm | 13 mm | 0.01 mm | 0.402 Kg |

| SX011824-A | 120 mm | 150 mm | 16 mm | 16 mm | 0.01 mm | 0.698 Kg |

| SX011828-A | 140 mm | 175 mm | 18 mm | 18 mm | 0.015 mm | 1.062 Kg |

| SX011832-A | 160 mm | 200 mm | 20 mm | 20 mm | 0.015 mm | 1.581 Kg |

| SX011836-A | 180 mm | 225 mm | 22 mm | 22 mm | 0.015 mm | 2.22 Kg |

| SX011840-A | 200 mm | 250 mm | 24 mm | 24 mm | 0.015 mm | 2.957 Kg |

| SX011848-A | 240 mm | 300 mm | 28 mm | 28 mm | 0.02 mm | 4.96 Kg |

| SX011860 | 300 mm | 380 mm | 38 mm | 38 mm | 0.02 mm | 11.6 Kg |

| SX011868 | 340 mm | 420 mm | 38 mm | 38 mm | 0.025 mm | 12.92 Kg |

| SX011880 | 400 mm | 500 mm | 46 mm | 46 mm | 0.03 mm | 23.221 Kg |

CRBH type dimension table

The inner and outer rings of CRBH type cross roller bearings are integral structures and have no mounting holes. They need to be fixed with flanges and support seats during installation. Its ultra-thin design makes it suitable for applications with smaller size requirements.

| Part Number | Seal Type | Bore Dia | Outer Dia | Width | Ring Material | Weight |

| CRBH30025A | Open | 300 mm | 360 mm | 25 mm | Steel | 5.29 Kg |

| CRBH30025AUU | Sealed | 300 mm | 360 mm | 25 mm | Steel | 5.29 Kg |

| CRBHV10020A | Open | 100 mm | 150 mm | 20 mm | Steel | 1.45 Kg |

| CRBHV10020AUU | Sealed | 100 mm | 150 mm | 20 mm | Steel | 1.45 Kg |

| CRBHV11020A | Open | 110 mm | 160 mm | 20 mm | Steel | 1.56 Kg |

| CRBHV11020AUU | Sealed | 110 mm | 160 mm | 20 mm | Steel | 1.56 Kg |

| CRBHV12025A | Open | 120 mm | 180 mm | 25 mm | Steel | 2.62 Kg |

| CRBHV12025AUU | Sealed | 120 mm | 180 mm | 25 mm | Steel | 2.62 Kg |

| CRBHV13025A | Open | 130 mm | 190 mm | 25 mm | Steel | 2.82 Kg |

| CRBHV13025AUU | Sealed | 130 mm | 190 mm | 25 mm | Steel | 2.82 Kg |

| CRBHV14025A | Open | 140 mm | 200 mm | 25 mm | Steel | 2.96 Kg |

| CRBHV14025AUU | Sealed | 140 mm | 200 mm | 25 mm | Steel | 2.96 Kg |

| CRBHV15025A | Open | 150 mm | 210 mm | 25 mm | Steel | 3.16 Kg |

| CRBHV15025AUU | Sealed | 150 mm | 210 mm | 25 mm | Steel | 3.16 Kg |

| CRBHV20025A | Open | 200 mm | 260 mm | 25 mm | Steel | 4 Kg |

| CRBHV20025AUU | Sealed | 200 mm | 260 mm | 25 mm | Steel | 4 Kg |

| CRBHV208A | Open | 20 mm | 36 mm | 8 mm | Steel | 0.04 Kg |

| CRBHV208AUU | Sealed | 20 mm | 36 mm | 8 mm | Steel | 0.04 Kg |

| CRBHV25025A | Open | 250 mm | 310 mm | 25 mm | Steel | 4.97 Kg |

| CRBHV25025AUU | Sealed | 250 mm | 310 mm | 25 mm | Steel | 4.97 Kg |

| CRBHV258A | Open | 25 mm | 41 mm | 8 mm | Steel | 0.05 Kg |

| CRBHV258AUU | Sealed | 25 mm | 41 mm | 8 mm | Steel | 0.05 Kg |

| CRBHV3010A | Open | 30 mm | 55 mm | 10 mm | Steel | 0.12 Kg |

| CRBHV3010AUU | Sealed | 30 mm | 55 mm | 10 mm | Steel | 0.12 Kg |

| CRBHV3510A | Open | 35 mm | 60 mm | 10 mm | Steel | 0.13 Kg |

| CRBHV3510AUU | Sealed | 35 mm | 60 mm | 10 mm | Steel | 0.13 Kg |

| CRBHV4010A | Open | 40 mm | 65 mm | 10 mm | Steel | 0.15 Kg |

| CRBHV4010AUU | Sealed | 40 mm | 65 mm | 10 mm | Steel | 0.15 Kg |

| CRBHV4510A | Open | 45 mm | 70 mm | 10 mm | Steel | 0.16 Kg |

| CRBHV4510AUU | Sealed | 45 mm | 70 mm | 10 mm | Steel | 0.16 Kg |

| CRBHV5013A | Open | 50 mm | 80 mm | 13 mm | Steel | 0.29 Kg |

| CRBHV5013AUU | Sealed | 50 mm | 80 mm | 13 mm | Steel | 0.29 Kg |

| CRBHV6013A | Open | 60 mm | 90 mm | 13 mm | Steel | 0.33 Kg |

| CRBHV6013AUU | Sealed | 60 mm | 90 mm | 13 mm | Steel | 0.33 Kg |

| CRBHV7013A | Open | 70 mm | 100 mm | 13 mm | Steel | 0.38 Kg |

| CRBHV7013AUU | Sealed | 70 mm | 100 mm | 13 mm | Steel | 0.38 Kg |

| CRBHV8016A | Open | 80 mm | 120 mm | 16 mm | Steel | 0.74 Kg |

| CRBHV8016AUU | Sealed | 80 mm | 120 mm | 16 mm | Steel | 0.74 Kg |

| CRBHV9016A | Open | 90 mm | 130 mm | 16 mm | Steel | 0.81 Kg |

| CRBHV9016AUU | Sealed | 90 mm | 130 mm | 16 mm | Steel | 0.81 Kg |

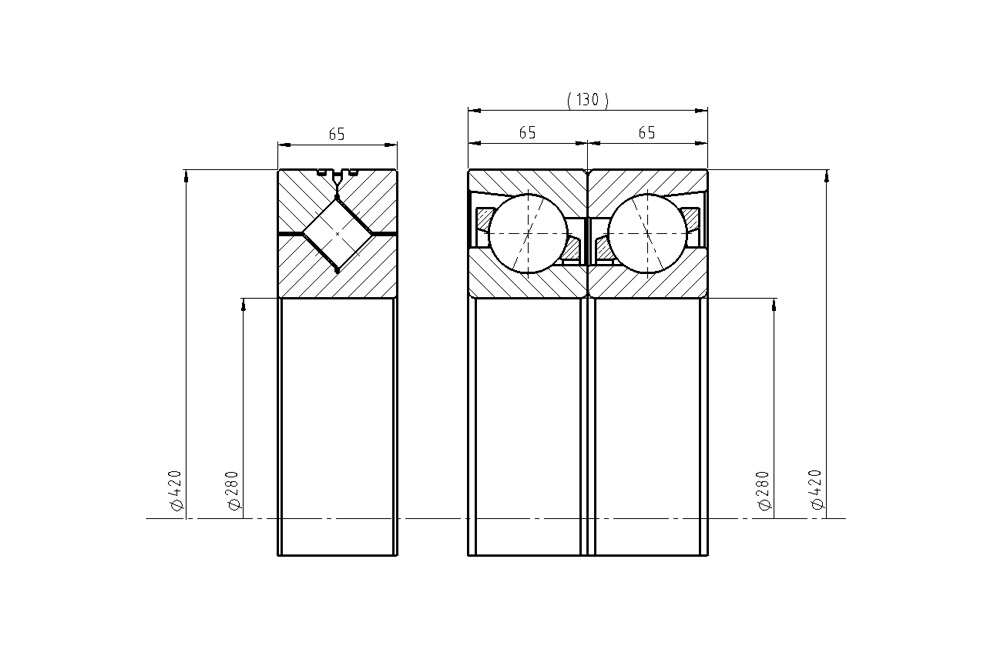

Crossed tapered roller bearings

Crossed tapered roller bearings consist of two rows of rollers that are perpendicular to each other and are arranged alternately in the raceway. The tilt angle and tapered geometry of the bearings enable them to withstand high axial and radial loads and provide high rigidity and precision. Crossed tapered roller bearings are often used in applications that require precise positioning and high load capacity, such as high-precision machine tools and large mechanical equipment.

Application of Crossed Roller Bearings

Crossed roller bearings are widely used in various mechanical equipment that require high precision, high rigidity and high load capacity. Here are some of the main application areas:

Robotics

Modern industrial robots require high-precision, high-speed and high-reliability motion mechanisms. As the key support and transmission element of the robot, crossed roller bearings can provide high rigidity, low inertia, low friction and long life support and transmission. For example, in the arms, waists, chassis and other parts of the robot, crossed roller bearings are widely used in various motion joints and rotation mechanisms, providing important guarantees for the stable operation of the robot.

Aerospace

In the field of aerospace, crossed roller bearings are widely used in the motion mechanisms of aircraft landing gear, missiles, drones and other equipment. Since aerospace equipment requires high-precision and high-stability support, crossed roller bearings can provide reliable support and transmission to ensure the stable operation of the equipment under high speed, high temperature and high load conditions.

Machine Tools

In the field of machine tools, crossed roller bearings are used in high-precision spindles and transmission systems to achieve high-precision workpiece processing. Crossed roller bearings can withstand harsh environments such as high speed, heavy load and high temperature, ensuring the stable operation of machine tools in high-precision processing. For example, on some high-end CNC machine tools, crossed roller bearings are used in spindle bearings and transmission bearings.

Medical equipment

Medical equipment requires high-precision, high-cleanliness and high-stability parts to achieve high-quality medical effects. As a key component in medical equipment, crossed roller bearings can provide high-precision, high-cleanliness and high-stability support and transmission. For example, in some high-end medical equipment, such as CT machines, nuclear magnetic resonance imaging, etc., crossed roller bearings are used in the motion mechanism and support mechanism of the equipment, which can withstand harsh environments such as high temperature, low temperature, vacuum and corrosion to ensure the stable operation of the equipment.

Automobile manufacturing

Automobile manufacturing requires high-precision, high-efficiency and high-reliability parts to achieve high-quality automobile production. As a key component in automobile manufacturing, crossed roller bearings can provide high-precision, high-efficiency and high-reliability support and transmission. For example, in the steering gear, transmission, suspension system and other parts of the car, crossed roller bearings are widely used in various motion joints and rotating mechanisms, providing important guarantees for the stable operation of the car.

Factors for selecting crossed roller bearings

Choosing the right crossed roller bearing model is crucial to the performance and life of mechanical equipment. Here are a few key factors to consider when selecting:

Bearing type

Choose the appropriate bearing type based on the specific application and load requirements of the equipment. Crossed cylindrical roller bearings are suitable for applications with large radial and axial loads, while crossed tapered roller bearings are suitable for applications that require high rigidity and high-precision positioning.

Bearing size

Before selecting, it is necessary to determine the bearing size based on the shaft size of the equipment and the reserved installation space. Ensure that the installation selection of the bearing meets the design requirements of the equipment and minimizes the installation space.

Bearing structure

Different crossed roller bearings have different structural designs, such as outer ring split type, inner ring split type and integral structure. Select the appropriate structure according to the specific installation requirements and rotating parts of the equipment.

Bearing load capacity

Understand the load capacity required by the equipment and select a crossed roller bearing with corresponding load capacity according to the load requirements of the equipment. Ensure that the bearing can withstand the load applied by the equipment during use.

Installation and maintenance

Consider the ease of installation and maintenance of the bearing. Choosing a bearing model that is easy to install and maintain can reduce the maintenance cost of the equipment and improve operating efficiency.

Conclusion

Cross roller bearings have a wide range of applications in modern industry due to their high precision, high rigidity and high load capacity. Through reasonable selection and proper maintenance, cross roller bearings can significantly improve the performance and life of equipment and meet the application requirements of high precision, high load and high stability.

FAQ

1. What applications are cross roller bearings suitable for?

Cross roller bearings are suitable for applications that require high precision, high rigidity and high load capacity, such as aerospace, robotics, machine tools, medical equipment and automobile manufacturing.

2. How to choose a suitable cross roller bearing model?

Choosing a suitable cross roller bearing model requires considering factors such as bearing type, size, structure, load capacity, and ease of installation and maintenance.

3. What are the maintenance requirements for cross roller bearings?

The maintenance requirements for cross roller bearings are relatively low. Generally, it is only necessary to regularly check the operating status of the bearings and replace damaged rolling elements in time. Its compact structural design also makes installation and disassembly convenient.

4. What is the difference between cross cylindrical roller bearings and cross tapered roller bearings?

Crossed cylindrical roller bearings are suitable for applications with large radial and axial loads, while crossed tapered roller bearings are suitable for applications that require high rigidity and high-precision positioning. The selection should be determined based on the specific application requirements.