Bearing Manufacturer & Supplier

Specialize in ball bearings, roller bearings, thrust bearings, thin section bearings etc.

Everything You Should Know About Sealed Bearings and Shielded Bearings

Sealed bearings and shielded bearings are almost as old as ball bearings. However, increasing demands on bearings have meant that the importance of bearing seals and shields has increased, moving from occasional add-on items to inherent parts. In special applications, seals or shields are increasingly becoming an integral part of the bearing design rather than additional additions.

Table of Contents

ToggleWhy Use Sealed or Shielded Bearings

The main impetus for sealed or shielded bearings is the increasing use of sealed bearings in everyday items such as white goods, automobiles and power tools. These bearings are lubricated with grease, so seals or shields are required to prevent the grease from leaking. This is especially true in applications where grease leakage could damage the product. But in most operating environments, the requirement is twofold: keep the lubricant inside the bearing while keeping moisture, debris and contaminants out.

Of course, ball bearings typically spin at high speeds while seals and shields provide protection. Therefore, if life is to be maximized, the type of seal or shield to be used must be selected considering not only the conditions but also the frictional effects of the equipment on the bearing starting and running torques.

In many cases, the literature on seals and shields tends to blur the differences between the two and the areas where one or the other should be used. Essentially, shields are non-contact metal (carbon steel or stainless steel) devices that allow high-speed operation with limited protection from moisture and dust. Seals can be contact or non-contact. The former offers better protection but reduced speed capabilities, while the latter has higher speed capabilities and a better level of protection than a shield.

The most important developments have occurred recently in the field of seals. Traditional seals for ball bearings are made of contact rubber, usually with a metal backing. On smaller bearing sizes, the seals are usually made of glass-reinforced Teflon and mounted using snap rings. Both types are very effective at keeping out water, liquids and fine particles. However, their operating speed is limited by the friction that exists between the seal and the inner ring of the bearing. The precise fit of standard contact seals also means that a small vent hole is required to ensure that pressure within the bearing does not ‘pop’ the seal and release the grease lubricant.

What is the difference between shielded and sealed bearings?

Shielded and sealed bearings can improve bearing performance and extend its service life. Bearings are used to reduce friction between the moving parts of a machine in order to achieve a desired speed – bearings reduce friction either by making no contact or simply lubricating. Also, it tends to support the support of different parts of the machine.

Two additional optional components, shielding or sealing, are added to the bearing to further enhance its performance. Both work for the same purpose, and they also have pros and cons. The shield is a metal disc, and the seal is inserted into a small groove.

What is a shielded bearing?

Shielded bearings are designed to prevent relatively large particles from entering the bearing. It helps keep the grease in the bearing. Shields have no contact points between the bearing inner ring and the bore of the shield. Metal shields are considered the most common and least expensive bearing type. They act as lubricants for rolling elements; reducing friction and preventing energy loss. Further, the rolling elements are protected from large contaminants during operation. However, they are not as perfect as they seem. It is impossible to remove the shield. Relubrication is therefore not possible. Also, excessive pressure can force the shield away from the cage.

Metal shielded bearings are often used in applications where there is a risk of contamination, where speed remains a priority as they have no contact with the inner ring, ensuring low friction levels. Therefore, metal shielded bearings are often used in place of rubber seals due to their speed capabilities. However, they are not as good at protecting against moisture and fine dust as rubber seals, so this needs to be considered when deciding whether metal shielded bearings are the best choice for your application.

What are sealed bearings?

A sealed bearing is a self-enclosed bearing, or as a separate unit, it can be called a closed unit. They can be pulled out quickly. The seal not only keeps debris out, but also keeps the lubricant inside.

With the help of sealed bearings, the bearings are wetted with grease, which provides additional protection. This means less oil leaks. Bearing seals keep impurities out of the part while preventing lubricant from seeping out. It does not require regular maintenance. They are impervious to external environmental contaminants, easy to handle, and space-saving. Plus, they’re environmentally friendly as there are far fewer oil spills. On the contrary, everything has pros and cons. The downside of a sealed bearing is that it can melt at higher temperatures because it is made of plastic and rubber.

Rubber-sealed bearings are considered maintenance-free because they are “sealed for life” and do not require relubrication. Rubber seals prevent loss of lubrication, and the bearings are preloaded with just the right amount of lubricant. Likewise, rubber seals keep moisture out of the bearings to avoid rust and ensure lubrication doesn’t get washed away. Speed is an important factor to consider when selecting a bearing. The speed of bearings with rubber seals may be affected due to the frictional forces that occur when contacting the inner and outer rings.

Now the question arises, which is the best bearing? Sealed or shielded? There are several factors in this ongoing debate that we discussed above. You have to know what your goal is. Sealing not only improves speed, but also protects your car from pollutants, although operating at high temperatures is risky; on the other hand, the shield can even withstand temperatures up to 250°F.

AUB Sealed And Shielded Bearings

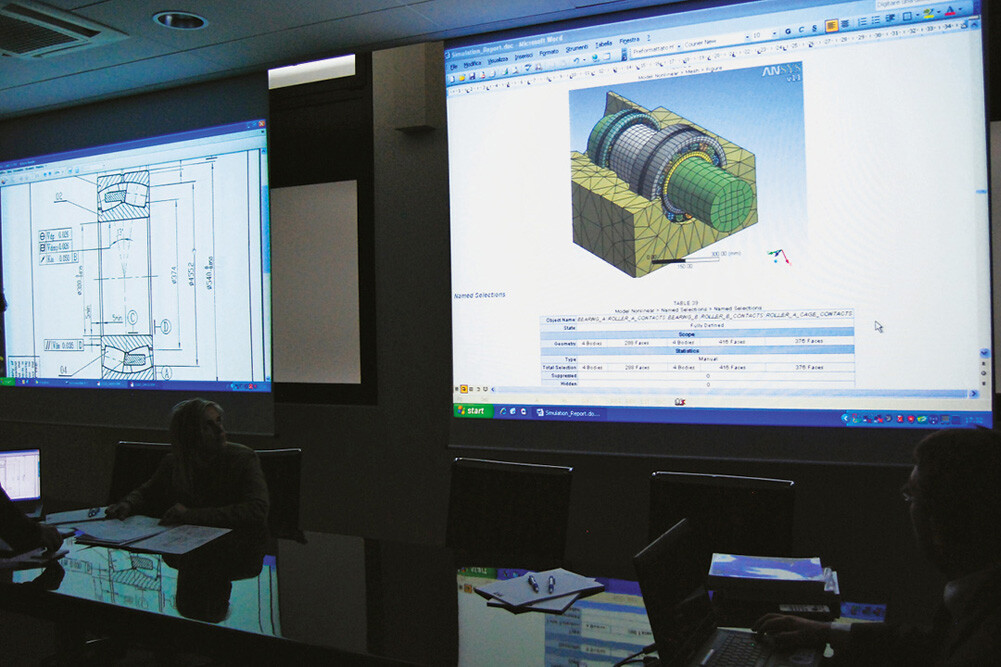

The challenge in recent years has been to develop a new generation of seals that combine a high level of sealing with a speed capability similar to that of a shield. AUB‘s V-seals have been developed for this purpose. Compared with conventional seals, the V-type is a non-contact device that is fixed in the outer ring of the bearing by the elasticity of the rubber seal material. With this design, friction is not an issue. Therefore, bearings with seals can be used at the same high speeds as bearings with shields. However, V-seals offer better grease sealing efficiency and resistance to fine dust particles than boots.

FAQS

What are ZZ and 2rs bearings?

There are two types of bearing caps. They can be shields or seals. These two are essential parts for deep groove bearings. Their main purpose is to protect and extend bearing life. They do this by inhibiting pollutants or impurities from reaching the interior area. Also, it stays lubricated, thus preventing friction.

There are two most common types of bearing caps, ZZ and 2rs. The Zz is a non-contacting, non-removable bearing enclosure with metal seals on both sides. Since they do not touch the inner race, they do not affect the speed of operation. 2rs are molded rubber seals on both sides of the bearing. It provides a better seal and protects against a contaminated environment, but over contact. Therefore, it increases friction. The ZZ is superior to the 2rs because it has zero contact with the inner ring and provides an excellent seal.

What does the ZZ on the bearing mean?

ZZ designates a non-removable, non-contact bearing closure with metal seals on both sides. It has metal shielding on both sides. With ZZ bearings, the bearing will work for a lifetime as it keeps dust and external contaminants out of its way.

Are sealed bearings waterproof?

Yes, sealed bearings are waterproof and dustproof. They guarantee longer bearing life when exposed to large quantities of airborne dust and splashed water. Therefore they are suitable for use underwater.

Do shielded bearings need lubrication?

According to the manufacturer’s instructions, they need to fail, but double shield bearings are lubricated for life and do not require this failure.

Can you lubricate sealed bearings?

Sealed bearings are typically used in low speed machines and have an expected life of about three years. These types of bearings fall into the category of Lubricated For Life bearings. They do not require lubrication as their lubrication level is longer than the expected life of the bearing.

What happens when you over lubricate your bearings?

Overlubricating a bearing will result in an increased volume of grease in the cavity. It causes the rotating bearing elements to start agitating the grease, pushing it away, causing further energy loss and temperature rise.