Bearing Manufacturer & Supplier

Specialize in ball bearings, roller bearings, thrust bearings, thin section bearings etc.

Everything You Should Know About Bearing Tolerances

What is a standard? Standards are documents that specify product, service and/or process requirements and specify their desired characteristics. This helps ensure the free flow of goods and encourages exports. It is used to protect people and goods and to improve quality in all areas of life. How was it developed? Standards are developed by those who need and are interested in using them. Extensive participation of all stakeholders, a transparent development process, and principles of consensus ensure that the standard is widely accepted.

Table of Contents

ToggleWhat Are Bearing Tolerance Classes?

Tolerance classes for ball bearings were defined by a committee within the ABMA known as the “Annular Bearings Engineers Committee” (ABEC). These tolerances are commonly referred to as ABEC rating, or grade. Tolerance classes for roller bearings are covered by the RBEC classifications contained within the same standard. These classes are defined in ABMA standard 20 – Radial Bearings of Ball, Cylindrical Roller, and Spherical Roller Types and ABMA standards 12.1 and 12.2 – Instrument Ball Bearings. The ABEC (and RBEC) tolerance classifications specify both tolerances of size and form for the individual inner and outer rings. The critical features of the rings include the bore (or inner diameter of the inner ring), the outer diameter of the outer ring, the ring widths, and the raceways of each ring. Tolerances of form include roundness, taper, runout, and parallelism.

What Are Instrument Series Ball Bearings?

ABMA standard 20 defines 5 classes: ABEC 1, ABEC 3, ABEC 5, ABEC 7, and ABEC 9. Instrument series ball bearings are defined in standards 12.1 and 12.2 and carry the suffix “P”. Extra thin and thin section ball bearings defined in standards 12.1 and 12.2 carry the suffix “T”. The higher the number of the classification, the tighter the tolerances become resulting in higher precision of the assembled bearing. When the classification system was first set up, machine tool technology was such that manufacturers mass-produced only ABEC 1, and sometimes ABEC 3. Bearings for the higher classifications were selected from the production runs of the lower classification. Today, the technology has advanced to the point where manufacturers can produce ABEC 7 and ABEC 9 bearings routinely.

While all bearings are extremely precise mechanisms, a designer must consider the benefits of tighter tolerances in terms of performance and bearing life. For example, there is a direct correlation between precision class and bearing life. Raceway parallelism, a feature controlled by ABEC, can impact bearing torque. A non-parallel raceway will result in torque spikes. In high-speed applications, bearing runout can result in an imbalance in the rotating mass. These conditions can lead to premature failure and unpredictable life. Of course, the higher precision levels have the downside of higher cost.

What Other Bearing Specifications Are Important?

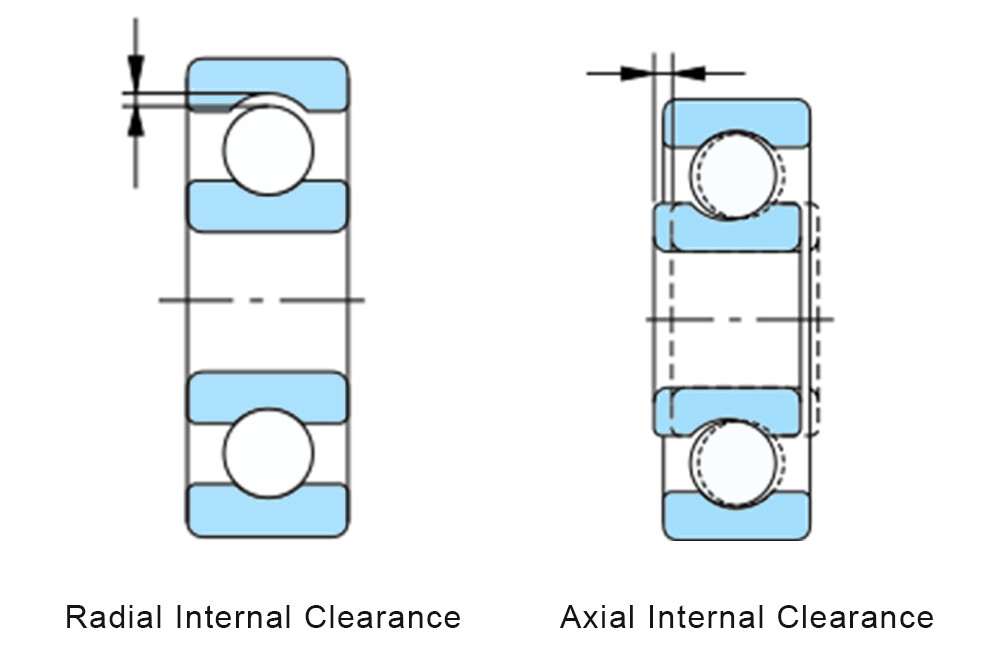

While bearing tolerance classes primarily govern the boundary dimensions of the rings, it should also be noted that some characteristics critical to bearing performance and life are not governed by ABEC (or ISO) specifications. These include internal clearance, surface finish, ball accuracy, torque, noise, cage type and lubrication. These items, along with the accuracy class, should be specified when selecting a bearing to ensure optimum life and performance. In many cases, it is one of these characteristics, rather than the level of precision, that, when specified correctly, yields the desired performance and/or lifetime.

Many countries in the world have their own standards organizations. For example, Germany, Japan, South Korea, Russia and China are major bearing manufacturing countries, all of which have industry standards covering both ball and roller bearings. In almost all cases, these standards are similar or equivalent to ISO 492.

DIN (Deutsches Institut fur Normung): DIN, the German Institute for Standardization, is an independent standardization platform in Germany and around the world. As a partner of industry, research and society at large, DIN plays an important role in supporting the marketization of innovative solutions through standardization. Their market-driven standards and norms facilitate global trade, encourage rationalization, quality assurance and environmental protection, and improve safety and communications.

JIS (Japanese Industrial Standards): The Japanese Industrial Standards Committee (JISC) is Japan’s national standardization body and plays a central role in developing Japanese standards, covering products and technologies ranging from robots to pictograms.

ISO (International Organization for Standardization): Through its members, it brings together experts to share knowledge and develop voluntary, consensus-based, market-relevant international standards that support innovation and provide solutions to global challenges.

Tolerance classes for ball bearings are defined by a committee within ABMA called the Annular Bearing Engineers Committee (ABEC). These tolerances are often referred to as ABEC ratings or grades. Tolerance classes for roller bearings are included in the RBEC classification contained in the same standard.

The ABEC (and RBEC) tolerance classes specify dimensional and form tolerances for individual inner and outer rings. Key features of the rings include the bore (or inner diameter of the inner ring), outer diameter of the outer ring, ring width and raceway of each ring. Form tolerances include roundness, taper, runout, and parallelism.

There are five classes from largest to smallest tolerance: ABEC 1, ABEC 3, ABEC 5, ABEC 7 and ABEC 9. Higher ABEC ratings offer better accuracy, efficiency, and the potential for higher speed capabilities, but do not necessarily allow components to spin faster. ABEC ratings do not specify many critical factors such as load handling capacity, ball accuracy, material, material Rockwell hardness, ball and raceway finish, noise, vibration and lubricants. Due to these factors, ABEC class 3 bearings may perform better than ABEC Class 7 bearings. Bearings that do not conform to at least ABEC 1 cannot be classified as precision bearings because their tolerances are too loose.

Although the factors related to material, manufacturing and performance are unknown, the scale can also guide consumers to make an informed decision about the type of bearing they want.

Highly rated bearings are used in precision applications such as aircraft instruments or surgical equipment. Low grade bearings are suitable for the vast majority of applications such as vehicles, hobby mechanics, skates, skateboards, fishing reels and industrial machinery. High ABEC rated bearings allow for optimum performance in critical applications requiring very high RPM and smooth operation.

| Standard | Applicable Standard | Tolerance Class | Bearing Types | ||||

|---|---|---|---|---|---|---|---|

| American National Standards Institute (ANSI) | ANSI/ABMA Std.20 | ABEC-1 / RBEC-1 | ABEC-3 / RBEC-3 | ABEC-5 / RBEC-5 | ABEC-7 | ABEC-9 | Radial bearings (Except tapered roller bearings) |

| American Bearing Manufacturer’s Association (ABMA) | ANSI/ABMA Std.19.1 | Class K | Class N | Class C | Class B | Class A | Tapered roller bearings (Metric series) |

| ANSI/ABMA Std.19 | Class 4 | Class 2 | Class 3 | Class 0 | Class 00 | Tapered roller bearings (Inch series) | |

| Deutsches Institut fur Normung (DIN) | DIN 620 | P0 | P6 | P5 | P4 | P2 | All type |

| Japanese Industrial Standard (JIS) | JIS B 1514 | Class 0,6X | Class 6 | Class 5 | Class 4 | Class 2 | All type |

| ISO 492 | Normal class | Class 6 | Class 5 | Class 4 | Class 2 | Radial bearings | |

| Class 6X | |||||||

| International Organization for Standardization (ISO) | ISO 199 | Normal Class | Class 6 | Class 5 | Class 4 | ー | Thrust ball bearings |

| ISO 578 | Class 4 | ー | Class 3 | Class 0 | Class 00 | Tapered roller bearings (Inch series) | |

| ISO 1224 | ー | ー | Class 5A | Class 4A | ー | Precision instrument bearings |

Bearing tolerance: refers to the accuracy of three aspects:

Dimensional Accuracy: Dimensional accuracy is a measure of the bearing’s external dimensions, For example, bore diameter (d), outer diameter (D), inner ring width (B), and outer ring width (C). The difference between an actual bearing dimension and the nominal or target value is called the dimensional deviation. The most commonly used measures are the single plane mean bore and outer diameter deviations (Admp and ADmp), and the inner and outer ring width deviations (ABs and ACs). These values are governed by industry standard tolerances. Dimensional accuracy is important for determining shaft and housing fits.

Machining Accuracy: Machining (or form) accuracy measures the variation in the above example dimensions when a series of measurements is taken on a single bearing and compared to one other. The most common measures are single radial plane bore and outside diameter variation (Vdp and VDp), mean single plane bore and outside diameter variation (Vdmp and VDmp), and inner and outer ring width variation (VBs and VCs). Variation refers to the difference between the largest and smallest measurements in a series, while mean variation refers to the average difference between consecutive measurements.

Running accuracy: Running accuracy (or runout) is a measure of the degree of eccentricity (for radial runout) and squareness (for bore and O.D. with side face) of the bearing. Inner and outer ring radial runout (Kia and Kea) are the measures most often used. Running accuracy is important to keep excess vibration and misalignment of the assembly at a minimum.

Allowable error limitations for the three areas of bearing accuracy have been internationally standardized for many years as tolerance classes. Each tolerance class specifies a group of limits for all the measures of accuracy (varying in proportion to the bearing size). The most recognized standards are compared in the table above (note that each column represents a set of equivalent classes). For the ISO, JIS, and DiN standards, bearings with standard accuracy are classified as class 0. This is then followed by class 6. From there on, decreasing class numbers denote progressively improving accuracy.

Radial Runout: Radial run-out is the variation of wall thickness in a bearing race. In technical terms, run-out is the measurement of the raceway in which the rolling element rides and how it relates to the outer ring’s outer diameter and the inner ring’s inner diameter as you rotate the bearing 360 degrees. Incorrect run-out can cause a wide variety of issues, depending on the application. For example, if you have a machine designed to create specially aligned holes in a part, incorrect run-out could affect the proper placement of the holes, meaning those holes might not match up with the mating part. In a motor application, you could face issues with vibration or noise.

Inner circle

bearing bore diameter

The bearing bore diameter is the diameter of the inner diameter of the inner ring. Measure the inside diameter at multiple locations and radial planes using a two-point measuring device. This measurement method can be used for all types of rolling bearings. If the size and weight of the bearing is such that the bore size is affected by gravity, the bearing should be placed in a horizontal position.

Inner ring width

Inner ring width refers to the individual width of the inner ring, not the overall width of the bearing. When measuring the width of the inner ring, one side of the inner ring is supported at three places, and the outer ring is free. The inner race width is measured with the calibration indicator opposite the three support locations.

Inner ring width deviation

Inner ring width deviation is the difference in width between the maximum and minimum width of the inner ring measured using the above method.

Radial runout of inner ring

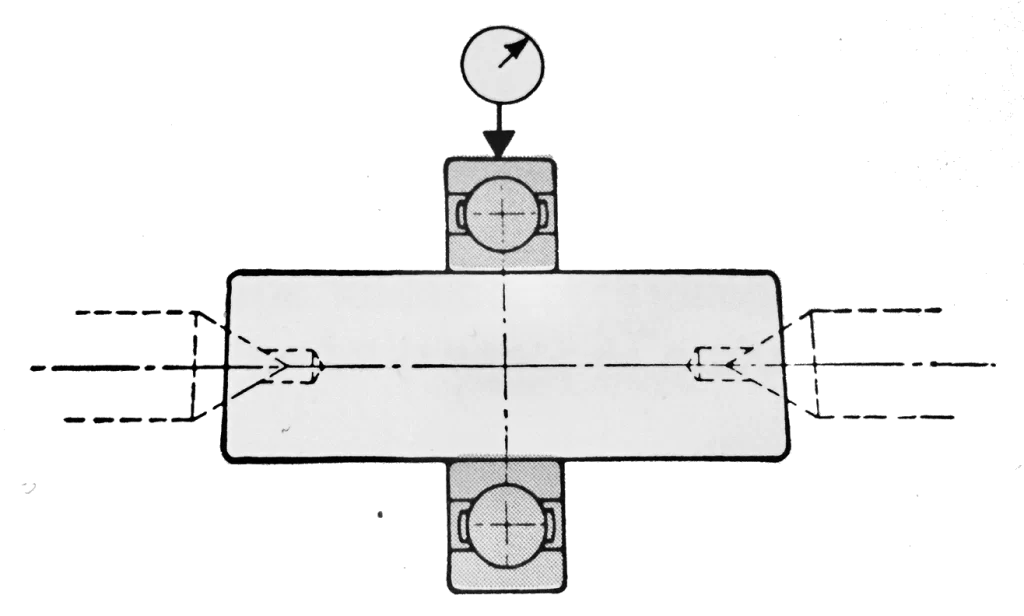

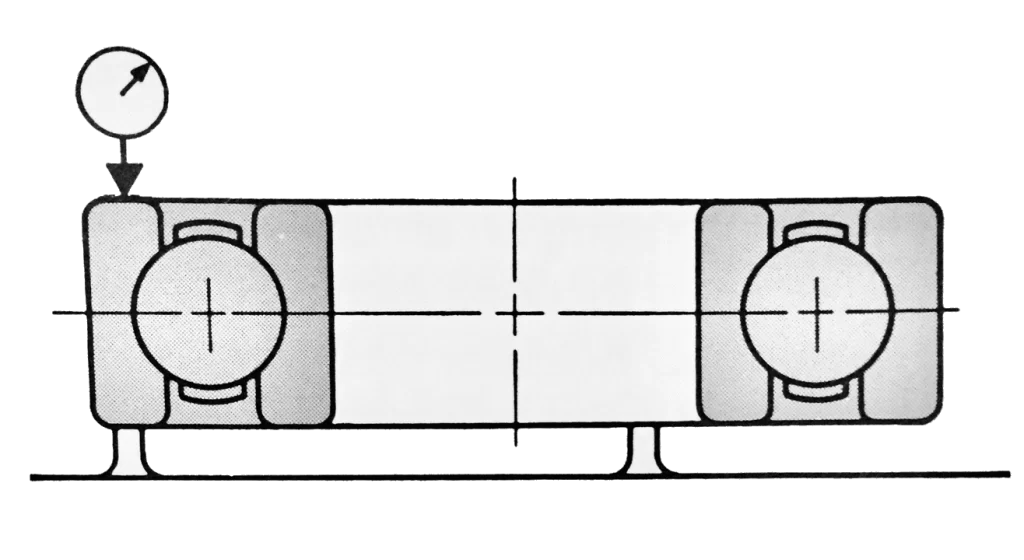

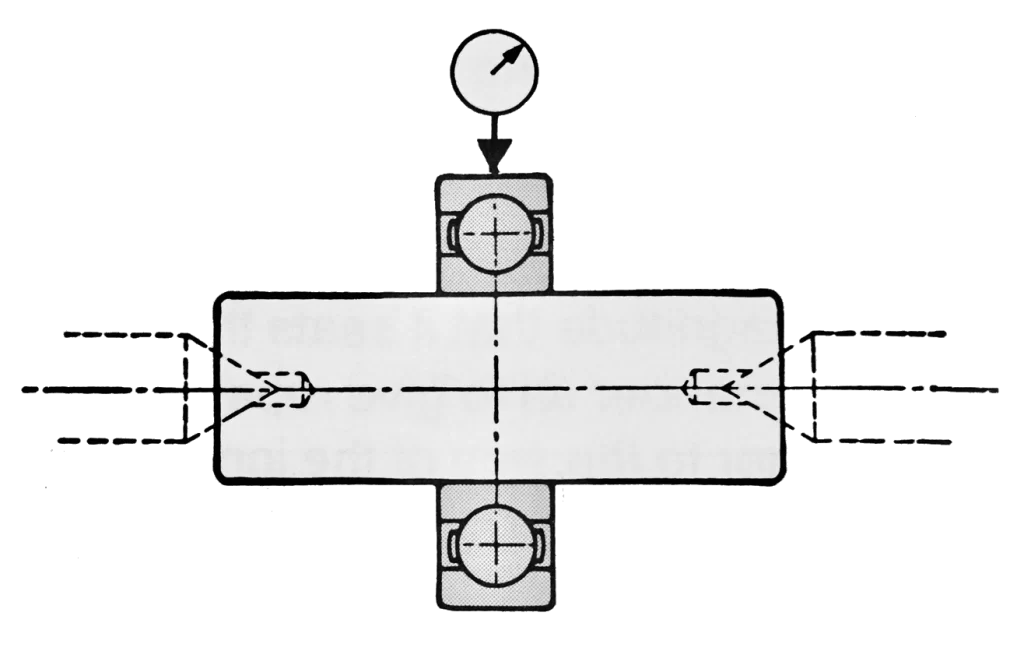

The runout of ball bearings (except angular contact bearings) is measured by mounting the bearing on a mandrel determined to be straight in diameter with a taper length of less than 0.0002 inches. The outer ring remains stationary while the inner ring (arbor) rotates a full revolution. The difference between the lowest and highest readings on an indicator placed in the center of the outer ring is the radial runout.

Outer Ring

Tolerance and measurement standards for outer rings are similar to those for inner rings.

Outside Diameter

The outside diameter of the outer ring is a two-point measuring technique that can be used on all rolling element bearing types. Measure the diameter of the bearing in several angular directions. If the size and weight of the bearing is such that the bore size is influenced by gravity, the bearing should be placed in a horizontal position.

Outer Ring Width

The outer ring is measured in much the same way as the inner ring. One side of the outer ring is supported in three places and the inner ring is free. The outer ring width is measured with a calibrated indicator opposite the three support locations.

Outer Ring Width Variation

As with inner ring width variation, outer ring width variation refers to the width difference between the largest and smallest width of the outer ring using the method indicated above.

Radial Runout

Radial runout for the outer ring is performed with the same setup that is used for measuring the inner ring radial runout, except the inner is held stationary and the outer ring is rotated one full revolution. The bearing is mounted on an arbor determined to have a diameter that is straight to less than .0002 in/inch length taper. The difference between the lowest and highest readings on an indicator placed in the center of the outer ring through one revolution of the outer ring is the radial runout.

Which Tolerance Class Is Best For My Application?

The following tables list the actual ABEC and RBEC tolerances per ABMA Standard 20. The tables list tolerances for both inner and outer rings, in both inch and metric units. These tables are useful in determining sizes and tolerance for components, such as shafts and housings. The designer should always do a tolerance stack up study at both maximum and least material conditions when sizing components, particularly when designing for miniature ball bearings. Some tolerances have been omitted for clarity. Tolerances for tapered roller bearings can be found in ABMA Standard 19.1 and are not included in these tables.

Table IA

Tolerance Class ABEC-1, RBEC-1-(ISO Class Normal)-Inner Ring (Tolerance values in 0.0001 inch)

| Bore Diameter (d) | Bore Tolerance (Δdmp) | Radial Runout (Kia) | Width Tolerance (ΔBS) | ||||||

|---|---|---|---|---|---|---|---|---|---|

| mm | inch | all | single bearing | paired bearings | |||||

| over | incl. | over | incl. | high | low | max. | high | low | |

| 0.6 | 2.5 | 0.0236 | 0.0984 | 0 | -3 | 4 | 0 | -16 | – |

| 2.5 | 10 | 0.0984 | 0.3937 | 0 | -3 | 4 | 0 | -47 | -98 |

| 10 | 18 | 0.3937 | 0.7087 | 0 | -3 | 4 | 0 | -47 | -98 |

| 18 | 30 | 0.7087 | 1.1811 | 0 | -4 | 5 | 0 | -47 | -98 |

| 30 | 50 | 1.1811 | 1.9685 | 0 | -4.5 | 6 | 0 | -47 | -98 |

| 50 | 80 | 1.9685 | 3.1496 | 0 | -6 | 8 | 0 | -59 | -150 |

| 80 | 120 | 3.1496 | 4.7244 | 0 | -8 | 10 | 0 | -79 | -150 |

| 120 | 180 | 4.7244 | 7.0866 | 0 | -10 | 12 | 0 | -98 | -197 |

| 180 | 250 | 7.0866 | 9.8425 | 0 | -12 | 16 | 0 | -118 | -197 |

| 250 | 315 | 9.8425 | 12.4016 | 0 | -14 | 20 | 0 | -138 | -197 |

| 315 | 400 | 12.4016 | 15.7480 | 0 | -16 | 24 | 0 | -157 | -248 |

Tolerance Class ABEC-1, RBEC-1-(ISO Class Normal)-Inner Ring (Tolerance values in micrometers)

| Bore Diameter (d) | Bore Tolerance (Δdmp) | Radial Runout (Kia) | Width Tolerance (ΔBS) | ||||||

|---|---|---|---|---|---|---|---|---|---|

| mm | inch | all | single bearing | paired bearings | |||||

| over | incl. | over | incl. | high | low | max. | high | low | |

| 0.6 | 2.5 | 0.0236 | 0.0984 | 0 | -8 | 10 | 0 | -40 | – |

| 2.5 | 10 | 0.0984 | 0.3937 | 0 | -8 | 10 | 0 | -120 | -250 |

| 10 | 18 | 0.3937 | 0.7087 | 0 | -8 | 10 | 0 | -120 | -250 |

| 18 | 30 | 0.7087 | 1.1811 | 0 | -10 | 13 | 0 | -120 | -250 |

| 30 | 50 | 1.1811 | 1.9685 | 0 | -12 | 15 | 0 | -120 | -250 |

| 50 | 80 | 1.9685 | 3.1496 | 0 | -15 | 20 | 0 | -150 | -380 |

| 80 | 120 | 3.1496 | 4.7244 | 0 | -20 | 25 | 0 | -200 | -380 |

| 120 | 180 | 4.7244 | 7.0866 | 0 | -25 | 30 | 0 | -250 | -500 |

| 180 | 250 | 7.0866 | 9.8425 | 0 | -30 | 40 | 0 | -300 | -500 |

| 250 | 315 | 9.8425 | 12.4016 | 0 | -35 | 50 | 0 | -350 | -500 |

| 315 | 400 | 12.4016 | 15.7480 | 0 | -40 | 60 | 0 | -400 | -630 |

Table IB

Tolerance Class ABEC-1, RBEC-1 (ISO Class Normal) – Outer Ring (Tolerance values in 0.0001 inch)

Outer Diameter (D)Outer Dia. Tolerance

| Outer Diameter (D) | Outer Dia. Tolerance (Δdmp) | Radial Runout (Kea) | Width Tolerance (ΔBS) | ||||||

|---|---|---|---|---|---|---|---|---|---|

| mm | inch | all | single bearing | paired bearings | |||||

| over | incl. | over | incl. | high | low | max. | high | low | |

| 2.5 | 6 | 0.0984 | 0.2362 | 0 | -3 | 6 | Identical to Width Tolerance (ΔBS) of Inner Ring of the same Bearing | ||

| 6 | 18 | 0.2362 | 0.7087 | 0 | -3 | 6 | |||

| 18 | 30 | 0.7087 | 1.1811 | 0 | -3.5 | 6 | |||

| 30 | 50 | 1.1811 | 1.9685 | 0 | -4.5 | 8 | |||

| 50 | 80 | 1.9685 | 3.1496 | 0 | -5 | 10 | |||

| 80 | 120 | 3.1496 | 4.7244 | 0 | -6 | 14 | |||

| 120 | 150 | 4.7244 | 5.9055 | 0 | -7 | 16 | |||

| 150 | 180 | 5.9055 | 7.0866 | 0 | -10 | 18 | |||

| 180 | 250 | 7.0866 | 9.8425 | 0 | -12 | 20 | |||

| 250 | 315 | 9.8425 | 12.4016 | 0 | -14 | 24 | |||

| 315 | 400 | 12.4016 | 15.7480 | 0 | -16 | 28 | |||

| 400 | 500 | 15.7480 | 19.6850 | 0 | -18 | 31 | |||

| 500 | 630 | 19.6850 | 24.8031 | 0 | -20 | 39 | |||

| 630 | 800 | 24.8031 | 31.4961 | 0 | -30 | 47 | |||

| 800 | 1000 | 31.4961 | 39.3701 | 0 | -39 | 55 | |||

Tolerance Class ABEC-1, RBEC-1 (ISO Class Normal) – Outer Ring (Tolerance values in micrometers)

| Outer Diameter (D) | Outer Dia. Tolerance (Δdmp) | Radial Runout (Kea) | Width Tolerance (ΔBS) | ||||||

|---|---|---|---|---|---|---|---|---|---|

| mm | inch | all | single bearing | paired bearings | |||||

| over | incl. | over | incl. | high | low | max. | high | low | |

| 2.5 | 6 | 0.0984 | 0.2362 | 0 | -8 | 15 | Identical to Width Tolerance (ΔBS) of Inner Ring of the same Bearing | ||

| 6 | 18 | 0.2362 | 0.7087 | 0 | -8 | 15 | |||

| 18 | 30 | 0.7087 | 1.1811 | 0 | -9 | 15 | |||

| 30 | 50 | 1.1811 | 1.9685 | 0 | -11 | 20 | |||

| 50 | 80 | 1.9685 | 3.1496 | 0 | -13 | 25 | |||

| 80 | 120 | 3.1496 | 4.7244 | 0 | -15 | 35 | |||

| 120 | 150 | 4.7244 | 5.9055 | 0 | -18 | 40 | |||

| 150 | 180 | 5.9055 | 7.0866 | 0 | -25 | 45 | |||

| 180 | 250 | 7.0866 | 9.8425 | 0 | -30 | 50 | |||

| 250 | 315 | 9.8425 | 12.4016 | 0 | -35 | 60 | |||

| 315 | 400 | 12.4016 | 15.7480 | 0 | -40 | 70 | |||

| 400 | 500 | 15.7480 | 19.6850 | 0 | -45 | 80 | |||

| 500 | 630 | 19.6850 | 24.8031 | 0 | -50 | 100 | |||

| 630 | 800 | 24.8031 | 31.4961 | 0 | -75 | 120 | |||

| 800 | 1000 | 31.4961 | 39.3701 | 0 | -100 | 140 | |||

Table II A

Tolerance Class ABEC-3, RBEC-3 (ISO Class 6)– Inner Ring (Tolerance values in 0.0001 inch)

| Bore Diameter (d) | Bore Tolerance (Δdmp) | Radial Runout (Kia) | Width Tolerance (ΔBS) | ||||||

|---|---|---|---|---|---|---|---|---|---|

| mm | inch | all | single bearing | paired bearings | |||||

| over | incl. | over | incl. | high | low | max. | high | low | |

| 0.6 | 2.5 | 0.0236 | 0.0984 | 0 | -3 | 2 | 0 | -16 | – |

| 2.5 | 10 | 0.0984 | 0.3937 | 0 | -3 | 2.5 | 0 | -47 | -98 |

| 10 | 18 | 0.3937 | 0.7087 | 0 | -3 | 3 | 0 | -47 | -98 |

| 18 | 30 | 0.7087 | 1.1811 | 0 | -3 | 3 | 0 | -47 | -98 |

| 30 | 50 | 1.1811 | 1.9685 | 0 | -4 | 4 | 0 | -47 | -98 |

| 50 | 80 | 1.9685 | 3.1496 | 0 | -4.5 | 4 | 0 | -59 | -150 |

| 80 | 120 | 3.1496 | 4.7244 | 0 | -6 | 5 | 0 | -79 | -150 |

| 120 | 180 | 4.7244 | 7.0866 | 0 | -7 | 7 | 0 | -98 | -197 |

| 180 | 250 | 7.0866 | 9.8425 | 0 | -8.5 | 8 | 0 | -118 | -197 |

| 250 | 315 | 9.8425 | 12.4016 | 0 | -10 | 10 | 0 | -138 | -197 |

| 315 | 400 | 12.4016 | 15.7480 | 0 | -16 | 24 | 0 | -157 | -248 |

Tolerance Class ABEC-3, RBEC-3 (ISO Class 6)– Inner Ring (Tolerance values in micrometers)

| Bore Diameter (d) | Bore Tolerance (Δdmp) | Radial Runout (Kia) | Width Tolerance (ΔBS) | ||||||

|---|---|---|---|---|---|---|---|---|---|

| mm | inch | all | single bearing | paired bearings | |||||

| over | incl. | over | incl. | high | low | max. | high | low | |

| 0.6 | 2.5 | 0.0236 | 0.0984 | 0 | -7 | 5 | 0 | -40 | – |

| 2.5 | 10 | 0.0984 | 0.3937 | 0 | -7 | 6 | 0 | -120 | -250 |

| 10 | 18 | 0.3937 | 0.7087 | 0 | -7 | 7 | 0 | -120 | -250 |

| 18 | 30 | 0.7087 | 1.1811 | 0 | -8 | 8 | 0 | -120 | -250 |

| 30 | 50 | 1.1811 | 1.9685 | 0 | -10 | 10 | 0 | -120 | -250 |

| 50 | 80 | 1.9685 | 3.1496 | 0 | -12 | 10 | 0 | -150 | -380 |

| 80 | 120 | 3.1496 | 4.7244 | 0 | -15 | 13 | 0 | -200 | -380 |

| 120 | 180 | 4.7244 | 7.0866 | 0 | -18 | 18 | 0 | -250 | -500 |

| 180 | 250 | 7.0866 | 9.8425 | 0 | -22 | 20 | 0 | -300 | -500 |

| 250 | 315 | 9.8425 | 12.4016 | 0 | -25 | 25 | 0 | -350 | -500 |

| 315 | 400 | 12.4016 | 15.7480 | 0 | -30 | 30 | 0 | -400 | -630 |

Table II B

Tolerance Class ABEC-3, RBEC-3 (ISO Class 6) —Outer Ring (Tolerance values in 0.0001 inch)

| Outer Diameter (D) | Outer Dia. Tolerance (Δdmp) | Radial Runout (Kea) | Width Tolerance (ΔBS) | ||||||

|---|---|---|---|---|---|---|---|---|---|

| mm | inch | all | single bearing | paired bearings | |||||

| over | incl. | over | incl. | high | low | max. | high | low | |

| 2.5 | 6 | 0.0984 | 0.2362 | 0 | -3 | 3 | Identical to Width Tolerance (ΔBS) of Inner Ring of the same Bearing | ||

| 6 | 18 | 0.2362 | 0.7087 | 0 | -3 | 3 | |||

| 18 | 30 | 0.7087 | 1.1811 | 0 | -3 | 3.5 | |||

| 30 | 50 | 1.1811 | 1.9685 | 0 | -3.5 | 4 | |||

| 50 | 80 | 1.9685 | 3.1496 | 0 | -4.5 | 5 | |||

| 80 | 120 | 3.1496 | 4.7244 | 0 | -5 | 7 | |||

| 120 | 150 | 4.7244 | 5.9055 | 0 | -6 | 8 | |||

| 150 | 180 | 5.9055 | 7.0866 | 0 | -7 | 9 | |||

| 180 | 250 | 7.0866 | 9.8425 | 0 | -8 | 10 | |||

| 250 | 315 | 9.8425 | 12.4016 | 0 | -10 | 12 | |||

| 315 | 400 | 12.4016 | 15.7480 | 0 | -11 | 14 | |||

| 400 | 500 | 15.7480 | 19.6850 | 0 | -13 | 16 | |||

| 500 | 630 | 19.6850 | 24.8031 | 0 | -20 | 39 | |||

| 630 | 800 | 24.8031 | 31.4961 | 0 | -18 | 24 | |||

| 800 | 1000 | 31.4961 | 39.3701 | 0 | -24 | 30 | |||

Tolerance Class ABEC-3, RBEC-3 (ISO Class 6) —Outer Ring (Tolerance values in micrometers)

| Outer Diameter (D) | Outer Dia. Tolerance (Δdmp) | Radial Runout (Kea) | Width Tolerance (ΔBS) | ||||||

|---|---|---|---|---|---|---|---|---|---|

| mm | inch | all | single bearing | paired bearings | |||||

| over | incl. | over | incl. | high | low | max. | high | low | |

| 2.5 | 6 | 0.0984 | 0.2362 | 0 | -7 | 8 | Identical to Width Tolerance (ΔBS) of Inner Ring of the same Bearing | ||

| 6 | 18 | 0.2362 | 0.7087 | 0 | -7 | 8 | |||

| 18 | 30 | 0.7087 | 1.1811 | 0 | -8 | 9 | |||

| 30 | 50 | 1.1811 | 1.9685 | 0 | -9 | 10 | |||

| 50 | 80 | 1.9685 | 3.1496 | 0 | -11 | 13 | |||

| 80 | 120 | 3.1496 | 4.7244 | 0 | -13 | 18 | |||

| 120 | 150 | 4.7244 | 5.9055 | 0 | -15 | 20 | |||

| 150 | 180 | 5.9055 | 7.0866 | 0 | -18 | 23 | |||

| 180 | 250 | 7.0866 | 9.8425 | 0 | -20 | 25 | |||

| 250 | 315 | 9.8425 | 12.4016 | 0 | -25 | 30 | |||

| 315 | 400 | 12.4016 | 15.7480 | 0 | -28 | 35 | |||

| 400 | 500 | 15.7480 | 19.6850 | 0 | -33 | 40 | |||

| 500 | 630 | 19.6850 | 24.8031 | 0 | -38 | 50 | |||

| 630 | 800 | 24.8031 | 31.4961 | 0 | -45 | 60 | |||

| 800 | 1000 | 31.4961 | 39.3701 | 0 | -60 | 75 | |||

Table III A

Tolerance Class ABEC-5, RBEC-5 – (ISO Class 5) – Inner Ring (Tolerance values in 0.0001 inch)

| Bore Diameter (d) | Bore Tolerance (Δdmp) | Radial Runout (Kia) | Width Tolerance (ΔBS) | ||||||

|---|---|---|---|---|---|---|---|---|---|

| mm | inch | all | single bearing | paired bearings | |||||

| over | incl. | over | incl. | high | low | max. | high | low | |

| 0.6 | 2.5 | 0.0236 | 0.0984 | 0 | -2 | 1.5 | 0 | -16 | -98 |

| 2.5 | 10 | 0.0984 | 0.3937 | 0 | -2 | 1.5 | 0 | -16 | -98 |

| 10 | 18 | 0.3937 | 0.7087 | 0 | -2 | 1.5 | 0 | -31 | -98 |

| 18 | 30 | 0.7087 | 1.1811 | 0 | -2.5 | 1.5 | 0 | -47 | -98 |

| 30 | 50 | 1.1811 | 1.9685 | 0 | -3 | 2 | 0 | -47 | -98 |

| 50 | 80 | 1.9685 | 3.1496 | 0 | -3.5 | 2 | 0 | -59 | -98 |

| 80 | 120 | 3.1496 | 4.7244 | 0 | -4 | 2.55 | 0 | -79 | -150 |

| 120 | 180 | 4.7244 | 7.0866 | 0 | -5 | 3 | 0 | -98 | -150 |

| 180 | 250 | 7.0866 | 9.8425 | 0 | -6 | 4 | 0 | -118 | -197 |

| 250 | 315 | 9.8425 | 12.4016 | 0 | -7 | 5 | 0 | -138 | -197 |

| 315 | 400 | 12.4016 | 15.7480 | 0 | -9 | 6 | 0 | -157 | -248 |

Tolerance Class ABEC-5, RBEC-5 – (ISO Class 5) – Inner Ring (Tolerance values in micrometers)

| Bore Diameter (d) | Bore Tolerance (Δdmp) | Radial Runout (Kia) | Width Tolerance (ΔBS) | ||||||

|---|---|---|---|---|---|---|---|---|---|

| mm | inch | all | single bearing | paired bearings | |||||

| over | incl. | over | incl. | high | low | max. | high | low | |

| 0.6 | 2.5 | 0.0236 | 0.0984 | 0 | -5 | 4 | 0 | -40 | -250 |

| 2.5 | 10 | 0.0984 | 0.3937 | 0 | -5 | 4 | 0 | -40 | -250 |

| 10 | 18 | 0.3937 | 0.7087 | 0 | -5 | 4 | 0 | -80 | -250 |

| 18 | 30 | 0.7087 | 1.1811 | 0 | -6 | 4 | 0 | -120 | -250 |

| 30 | 50 | 1.1811 | 1.9685 | 0 | -8 | 5 | 0 | -120 | -250 |

| 50 | 80 | 1.9685 | 3.1496 | 0 | -9 | 5 | 0 | -150 | -250 |

| 80 | 120 | 3.1496 | 4.7244 | 0 | -10 | 6 | 0 | -200 | -380 |

| 120 | 180 | 4.7244 | 7.0866 | 0 | -13 | 8 | 0 | -250 | -380 |

| 180 | 250 | 7.0866 | 9.8425 | 0 | -15 | 10 | 0 | -300 | -500 |

| 250 | 315 | 9.8425 | 12.4016 | 0 | -18 | 13 | 0 | -350 | -500 |

| 315 | 400 | 12.4016 | 15.7480 | 0 | -23 | 15 | 0 | -400 | -630 |

Table III B

Tolerance Class ABEC-5, RBEC-5 – (ISO Class 5) – Outer Ring (Tolerance values in 0.0001 inch)

| Outer Diameter (D) | Outer Dia. Tolerance (Δdmp) | Radial Runout (Kea) | Width Tolerance (ΔBS) | ||||||

|---|---|---|---|---|---|---|---|---|---|

| mm | inch | all | single bearing | paired bearings | |||||

| over | incl. | over | incl. | high | low | max. | high | low | |

| 2.5 | 6 | 0.0984 | 0.2362 | 0 | -2 | 2 | Identical to Width Tolerance (ΔBS) of Inner Ring of the same Bearing | ||

| 6 | 18 | 0.2362 | 0.7087 | 0 | -2 | 2 | |||

| 18 | 30 | 0.7087 | 1.1811 | 0 | -2.5 | 2.5 | |||

| 30 | 50 | 1.1811 | 1.9685 | 0 | -3 | 3 | |||

| 50 | 80 | 1.9685 | 3.1496 | 0 | -3.5 | 3 | |||

| 80 | 120 | 3.1496 | 4.7244 | 0 | -4 | 4 | |||

| 120 | 150 | 4.7244 | 5.9055 | 0 | -4.5 | 4.5 | |||

| 150 | 180 | 5.9055 | 7.0866 | 0 | -5 | 5 | |||

| 180 | 250 | 7.0866 | 9.8425 | 0 | -6 | 6 | |||

| 250 | 315 | 9.8425 | 12.4016 | 0 | -7 | 7 | |||

| 315 | 400 | 12.4016 | 15.7480 | 0 | -8 | 8 | |||

| 400 | 500 | 15.7480 | 19.6850 | 0 | -9 | 9 | |||

| 500 | 630 | 19.6850 | 24.8031 | 0 | -11 | 10 | |||

| 630 | 800 | 24.8031 | 31.4961 | 0 | -14 | 12 | |||

Tolerance Class ABEC-5, RBEC-5 – (ISO Class 5) – Outer Ring (Tolerance values in micrometers)

| Outer Diameter (D) | Outer Dia. Tolerance (Δdmp) | Radial Runout (Kea) | Width Tolerance (ΔBS) | ||||||

|---|---|---|---|---|---|---|---|---|---|

| mm | inch | all | single bearing | paired bearings | |||||

| over | incl. | over | incl. | high | low | max. | high | low | |

| 2.5 | 6 | 0.0984 | 0.2362 | 0 | -5 | 5 | Identical to Width Tolerance (ΔBS) of Inner Ring of the same Bearing | ||

| 6 | 18 | 0.2362 | 0.7087 | 0 | -5 | 5 | |||

| 18 | 30 | 0.7087 | 1.1811 | 0 | -6 | 6 | |||

| 30 | 50 | 1.1811 | 1.9685 | 0 | -6 | 6 | |||

| 50 | 80 | 1.9685 | 3.1496 | 0 | -9 | 8 | |||

| 80 | 120 | 3.1496 | 4.7244 | 0 | -10 | 10 | |||

| 120 | 150 | 4.7244 | 5.9055 | 0 | -11 | 11 | |||

| 150 | 180 | 5.9055 | 7.0866 | 0 | -13 | 13 | |||

| 180 | 250 | 7.0866 | 9.8425 | 0 | -15 | 15 | |||

| 250 | 315 | 9.8425 | 12.4016 | 0 | -18 | 18 | |||

| 315 | 400 | 12.4016 | 15.7480 | 0 | -20 | 20 | |||

| 400 | 500 | 15.7480 | 19.6850 | 0 | -23 | 23 | |||

| 500 | 630 | 19.6850 | 24.8031 | 0 | -28 | 25 | |||

| 630 | 800 | 24.8031 | 31.4961 | 0 | -35 | 30 | |||

Table IV A

Tolerance Class ABEC-7, RBEC-7 (ISO Class 4) Inner Ring – Tolerance values in 0.0001 inch

| Bore Diameter (d) | Bore Tolerance (Δdmp) | Radial Runout (Kia) | Width Tolerance (ΔBS) | ||||||

|---|---|---|---|---|---|---|---|---|---|

| mm | inch | all | single bearing | paired bearings | |||||

| over | incl. | over | incl. | high | low | max. | high | low | |

| 0.6 | 2.5 | 0.0236 | 0.0984 | 0 | -1.5 | 1 | 0 | -16 | -98 |

| 2.5 | 10 | 0.0984 | 0.3937 | 0 | -1.5 | 1 | 0 | -16 | -98 |

| 10 | 18 | 0.3937 | 0.7087 | 0 | -1.5 | 1 | 0 | -31 | -98 |

| 18 | 30 | 0.7087 | 1.1811 | 0 | -2 | 1 | 0 | -47 | -98 |

| 30 | 50 | 1.1811 | 1.9685 | 0 | -2.5 | 1.5 | 0 | -47 | -98 |

| 50 | 80 | 1.9685 | 3.1496 | 0 | -3 | 1.5 | 0 | -59 | -98 |

| 80 | 120 | 3.1496 | 4.7244 | 0 | -3 | 2 | 0 | -79 | -150 |

| 120 | 180 | 4.7244 | 7.0866 | 0 | -4 | 2.5 | 0 | -98 | -150 |

| 180 | 250 | 7.0866 | 9.8425 | 0 | -4.5 | 3 | 0 | -118 | -197 |

Tolerance Class ABEC-7, RBEC-7 (ISO Class 4) Inner Ring – Tolerance values in micrometers

| Bore Diameter (d) | Bore Tolerance (Δdmp) | Radial Runout (Kia) | Width Tolerance (ΔBS) | ||||||

|---|---|---|---|---|---|---|---|---|---|

| mm | inch | all | single bearing | paired bearings | |||||

| over | incl. | over | incl. | high | low | max. | high | low | |

| 0.6 | 2.5 | 0.0236 | 0.0984 | 0 | -4 | 2.5 | 0 | -40 | -250 |

| 2.5 | 10 | 0.0984 | 0.3937 | 0 | -4 | 2.5 | 0 | -40 | -250 |

| 10 | 18 | 0.3937 | 0.7087 | 0 | -4 | 2.5 | 0 | -80 | -250 |

| 18 | 30 | 0.7087 | 1.1811 | 0 | -5 | 3 | 0 | -120 | -250 |

| 30 | 50 | 1.1811 | 1.9685 | 0 | -6 | 4 | 0 | -120 | -250 |

| 50 | 80 | 1.9685 | 3.1496 | 0 | -7 | 4 | 0 | -150 | -250 |

| 80 | 120 | 3.1496 | 4.7244 | 0 | -8 | 5 | 0 | -200 | -380 |

| 120 | 180 | 4.7244 | 7.0866 | 0 | -10 | 6 | 0 | -250 | -380 |

| 180 | 250 | 7.0866 | 9.8425 | 0 | -12 | 8 | 0 | -300 | -500 |

Table IV B

Tolerance Class ABEC-7, RBEC-7 (ISO Class 4) Outer Ring — Tolerance values in 0.0001 inch

| Outer Diameter (D) | Outer Dia. Tolerance (Δdmp) | Radial Runout (Kea) | Width Tolerance (ΔBS) | ||||||

|---|---|---|---|---|---|---|---|---|---|

| mm | inch | all | single bearing | paired bearings | |||||

| over | incl. | over | incl. | high | low | max. | high | low | |

| 2.5 | 6 | 0.0984 | 0.2362 | 0 | -1.5 | 1 | Identical to Width Tolerance (ΔBS) of Inner Ring of the same Bearing | ||

| 6 | 18 | 0.2362 | 0.7087 | 0 | -1.5 | 1 | |||

| 18 | 30 | 0.7087 | 1.1811 | 0 | -2 | 1.5 | |||

| 30 | 50 | 1.1811 | 1.9685 | 0 | -2.5 | 2 | |||

| 50 | 80 | 1.9685 | 3.1496 | 0 | -3 | 2 | |||

| 80 | 120 | 3.1496 | 4.7244 | 0 | -3 | 2.5 | |||

| 120 | 150 | 4.7244 | 5.9055 | 0 | -3.5 | 3 | |||

| 150 | 180 | 5.9055 | 7.0866 | 0 | -4 | 3 | |||

| 180 | 250 | 7.0866 | 9.8425 | 0 | -4.5 | 4 | |||

| 250 | 315 | 9.8425 | 12.4016 | 0 | -5 | 4.5 | |||

| 315 | 400 | 12.4016 | 15.7480 | 0 | -6 | 5 | |||

Tolerance Class ABEC-7, RBEC-7 (ISO Class 4) Outer Ring — Tolerance values in micrometers

| Outer Diameter (D) | Outer Dia. Tolerance (Δdmp) | Radial Runout (Kea) | Width Tolerance (ΔBS) | ||||||

|---|---|---|---|---|---|---|---|---|---|

| mm | inch | all | single bearing | paired bearings | |||||

| over | incl. | over | incl. | high | low | max. | high | low | |

| 2.5 | 6 | 0.0984 | 0.2362 | 0 | -4 | 3 | Identical to Width Tolerance (ΔBS) of Inner Ring of the same Bearing | ||

| 6 | 18 | 0.2362 | 0.7087 | 0 | -4 | 3 | |||

| 18 | 30 | 0.7087 | 1.1811 | 0 | -5 | 4 | |||

| 30 | 50 | 1.1811 | 1.9685 | 0 | -6 | 5 | |||

| 50 | 80 | 1.9685 | 3.1496 | 0 | -7 | 5 | |||

| 80 | 120 | 3.1496 | 4.7244 | 0 | -8 | 6 | |||

| 120 | 150 | 4.7244 | 5.9055 | 0 | -9 | 7 | |||

| 150 | 180 | 5.9055 | 7.0866 | 0 | -10 | 8 | |||

| 180 | 250 | 7.0866 | 9.8425 | 0 | -11 | 10 | |||

| 250 | 315 | 9.8425 | 12.4016 | 0 | -13 | 11 | |||

| 315 | 400 | 12.4016 | 15.7480 | 0 | -15 | 13 | |||

Table V A

Tolerance Class ABEC-9, RBEC-9 ISO Class 2) Inner Ring –Tolerance values in 0.0001 inch

| Bore Diameter (d) | Bore Tolerance (Δdmp) | Radial Runout (Kia) | Width Tolerance (ΔBS) | ||||||

|---|---|---|---|---|---|---|---|---|---|

| mm | inch | all | single bearing | paired bearings | |||||

| over | incl. | over | incl. | high | low | max. | high | low | |

| 0.6 | 2.5 | 0.0236 | 0.0984 | 0 | -1 | 0.5 | 0 | -16 | -98 |

| 2.5 | 10 | 0.0984 | 0.3937 | 0 | -1 | 0.5 | 0 | -16 | -98 |

| 10 | 18 | 0.3937 | 0.7087 | 0 | -1 | 0.5 | 0 | -31 | -98 |

| 18 | 30 | 0.7087 | 1.1811 | 0 | -1 | 1 | 0 | -47 | -98 |

| 30 | 50 | 1.1811 | 1.9685 | 0 | -1 | 1 | 0 | -47 | -98 |

| 50 | 80 | 1.9685 | 3.1496 | 0 | -1.5 | 1 | 0 | -59 | -98 |

| 80 | 120 | 3.1496 | 4.7244 | 0 | -2 | 1 | 0 | -79 | -150 |

| 120 | 150 | 4.7244 | 5.9055 | 0 | -3 | 1 | 0 | -98 | -150 |

| 150 | 180 | 5.9055 | 7.0866 | 0 | -3 | 2 | 0 | -98 | -150 |

| 180 | 250 | 7.0866 | 9.8425 | 0 | -3 | 2 | 0 | -118 | -197 |

Tolerance Class ABEC-9, RBEC-9 ISO Class 2) Inner Ring –Tolerance values in micrometers

| Bore Diameter (d) | Bore Tolerance (Δdmp) | Radial Runout (Kia) | Width Tolerance (ΔBS) | ||||||

|---|---|---|---|---|---|---|---|---|---|

| mm | inch | all | single bearing | paired bearings | |||||

| over | incl. | over | incl. | high | low | max. | high | low | |

| 0.6 | 2.5 | 0.0236 | 0.0984 | 0 | -2.5 | 1.5 | 0 | -40 | -250 |

| 2.5 | 10 | 0.0984 | 0.3937 | 0 | -2.5 | 1.5 | 0 | -40 | -250 |

| 10 | 18 | 0.3937 | 0.7087 | 0 | -2.5 | 1.5 | 0 | -80 | -250 |

| 18 | 30 | 0.7087 | 1.1811 | 0 | -2.5 | 2.5 | 0 | -120 | -250 |

| 30 | 50 | 1.1811 | 1.9685 | 0 | -2.5 | 2.5 | 0 | -120 | -250 |

| 50 | 80 | 1.9685 | 3.1496 | 0 | -4 | 2.5 | 0 | -150 | -250 |

| 80 | 120 | 3.1496 | 4.7244 | 0 | -5 | 2.5 | 0 | -200 | -380 |

| 120 | 150 | 4.7244 | 5.9055 | 0 | -7 | 2.5 | 0 | -250 | -380 |

| 150 | 180 | 5.9055 | 7.0866 | 0 | -7 | 5 | 0 | -250 | -380 |

| 180 | 250 | 7.0866 | 9.8425 | 0 | -8 | 5 | 0 | -300 | -500 |

Table V B

Tolerance Class ABEC-9, RBEC-9 (ISO Class 2) Outer Ring —Tolerance values in 0.0001 inch

| Outer Diameter (D) | Outer Dia. Tolerance (Δdmp) | Radial Runout (Kea) | Width Tolerance (ΔBS) | ||||||

|---|---|---|---|---|---|---|---|---|---|

| mm | inch | all | single bearing | paired bearings | |||||

| over | incl. | over | incl. | high | low | max. | high | low | |

| 2.5 | 6 | 0.0984 | 0.2362 | 0 | -1 | 0.5 | Identical to Width Tolerance (ΔBS) of Inner Ring of the same Bearing | ||

| 6 | 18 | 0.2362 | 0.7087 | 0 | -1 | 0.5 | |||

| 18 | 30 | 0.7087 | 1.1811 | 0 | -1 | 0.5 | |||

| 30 | 50 | 1.1811 | 1.9685 | 0 | -1.5 | 1 | |||

| 50 | 80 | 1.9685 | 3.1496 | 0 | -1.5 | 1.5 | |||

| 80 | 120 | 3.1496 | 4.7244 | 0 | -2 | 2 | |||

| 120 | 150 | 4.7244 | 5.9055 | 0 | -2 | 2 | |||

| 150 | 180 | 5.9055 | 7.0866 | 0 | -3 | 2 | |||

| 180 | 250 | 7.0866 | 9.8425 | 0 | -3 | 3 | |||

| 250 | 315 | 9.8425 | 12.4016 | 0 | -3 | 3 | |||

| 315 | 400 | 12.4016 | 15.7480 | 0 | -4 | 3 | |||

Tolerance Class ABEC-9, RBEC-9 (ISO Class 2) Outer Ring –Tolerance values in micrometers

Outer Diameter (D)Outer Dia. Tolerance

| Outer Diameter (D) | Outer Dia. Tolerance (Δdmp) | Radial Runout (Kea) | Width Tolerance (ΔBS) | ||||||

|---|---|---|---|---|---|---|---|---|---|

| mm | inch | all | single bearing | paired bearings | |||||

| over | incl. | over | incl. | high | low | max. | high | low | |

| 2.5 | 6 | 0.0984 | 0.2362 | 0 | -2.5 | 1.5 | Identical to Width Tolerance (ΔBS) of Inner Ring of the same Bearing | ||

| 6 | 18 | 0.2362 | 0.7087 | 0 | -2.5 | 1.5 | |||

| 18 | 30 | 0.7087 | 1.1811 | 0 | -4 | 2.5 | |||

| 30 | 50 | 1.1811 | 1.9685 | 0 | -4 | 2.5 | |||

| 50 | 80 | 1.9685 | 3.1496 | 0 | -4 | 4 | |||

| 80 | 120 | 3.1496 | 4.7244 | 0 | -5 | 5 | |||

| 120 | 150 | 4.7244 | 5.9055 | 0 | -5 | 5 | |||

| 150 | 180 | 5.9055 | 7.0866 | 0 | -7 | 5 | |||

| 180 | 250 | 7.0866 | 9.8425 | 0 | -8 | 7 | |||

| 250 | 315 | 9.8425 | 12.4016 | 0 | -8 | 7 | |||

| 315 | 400 | 12.4016 | 15.7480 | 0 | -10 | 8 | |||