Bearing Manufacturer & Supplier

Specialize in ball bearings, roller bearings, thrust bearings, thin section bearings etc.

Everything About Crossed Roller Bearings

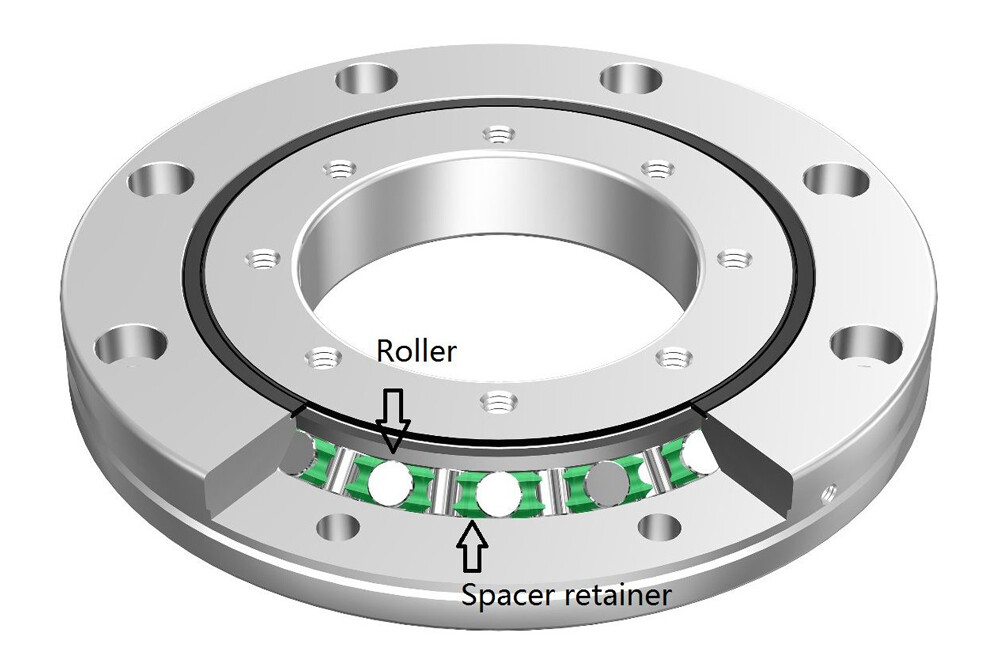

The rolling elements of crossed roller bearings generally use cylindrical rollers or tapered rollers arranged crosswise on a single raceway. The rollers are separated by cages or spacers. Crossed roller bearings have high rotation accuracy, large load-bearing capacity, small dimensions, high rotation speed and rigidity, and have a wide range of applications. Uses and advantages that other types of bearings cannot match. Generally speaking, according to different rolling elements, crossed roller bearings can be divided into crossed cylindrical roller bearings and crossed tapered roller bearings. This sharing is all the information you should know about crossed cylindrical roller bearings.

Table of Contents

ToggleStructural features of crossed cylindrical roller bearings

Crossed roller bearings are now used on industrial robots, because roller bearings are a special type of bearing with a divided inner ring and rotating outer ring. At the same time, roller bearings can withstand loads in all directions and have a strong ability to complete some comparisons. High-precision rotational movement, so it is now widely used. Let us understand the characteristics of crossed cylindrical roller bearings.

Easy to operate and install

Crossed roller bearings are divided into two parts, the outer ring or the inner ring. After the rollers and retainers are installed, they are fixed together, so the installation operation is very simple. When the inner and outer rings are integrated, if both inner and outer rings have mounting holes, there is no need for fixed flanges and support seats during installation. If the ultra-thin model has no mounting holes, the flange and support base must be fixed.

Saving space

The dimensions of the inner and outer rings of crossed cylindrical roller bearings have been miniaturized to a minimum. The ultra-thin structure in particular has a small size close to the limit and has high rigidity, so it is suitable for the joints or rotating parts of industrial robots and the rotation of machining centers. It is widely used in work tables, robot rotating parts, precision rotating tables, medical instruments, measuring instruments, IC manufacturing equipment, etc.

Excellent rotation accuracy

As mentioned before, the internal structure of crossed cylindrical roller bearings uses rollers arranged perpendicularly at 90° to each other. Spacers or isolation blocks can prevent friction between the rollers caused by the tilt of the rollers. In addition, there will be no contact or locking of one roller; at the same time, because the inner and outer rings are divided structures, the gap can be adjusted, and high-precision rotation can be obtained even if preload is applied.

Bear axial and radial loads

The internal structure of a crossed roller bearing usually consists of two annular tracks with cylindrical rollers. The rollers on the track are arranged in a cross arrangement, and the axis of each roller is perpendicular to the axis of rotation of the bearing. This cross arrangement makes the bearings have high rigidity and precision, and can withstand loads in all directions such as large radial loads, axial loads and moment loads.

Rolling elements

The rolling elements of crossed roller bearings are cylindrical rollers, and their surfaces are highly precision ground and polished, resulting in high geometric accuracy and low surface roughness. In addition, the diameter and length of the cylindrical rollers are larger than those of ordinary bearings, which makes the rolling elements have higher load-bearing capacity and rigidity.

Orbit accuracy

The track accuracy of crossed roller bearings is very high, and quenching treatment and precision grinding technology are usually used to ensure the geometric accuracy and surface hardness of the track. In addition, the rollers on the track are arranged in a cross arrangement, so that the bearing can better distribute the load when it is loaded, thus improving the rigidity and accuracy of the bearing.

Sealing performance

Crossed roller bearings are usually sealed with sealing rings to prevent dust, moisture and other impurities from entering the interior of the bearing. The material of the sealing ring is usually wear-resistant, high-temperature-resistant, corrosion-resistant synthetic rubber or polytetrafluoroethylene, which can ensure the long life and reliability of the bearing.

Service life

Crossed roller bearings have a long service life due to their high precision, high rigidity and high sealing performance. Under normal conditions, its service life can reach than tens of thousands of hours, and it is suitable for various high-precision, high-rigidity, and high-reliability mechanical systems.

Wide scope of application

On the basis of the basic crossed cylindrical roller bearing, many structurally different crossed cylindrical roller bearings are derived to facilitate use in occasions with different requirements. From the broad category, it can be divided into: basic crossed cylindrical roller bearings, high rigidity crossed cylindrical roller bearings, ultra-thin crossed cylindrical roller bearings; from the external structure, there are inner ring split type and outer ring split type type, integrated inner and outer ring type; from the internal structure, it can be divided into full roller type, metal window cage type, nylon or metal isolation block type; according to the connection method, there are bolt connection type and rivet connection type Type and spring disc type, etc., there are many types.

In addition to the above unique features, crossed cylindrical roller bearings also have high rotational speeds; they can reduce shaft length and processing costs, and have limited changes in geometric dimensions caused by thermal expansion; they use nylon separators to have low rotational inertia, low starting torque, and easy control of angles. Indexing; optimized preload force, high rigidity, high precision of guide roller operation; sufficient lubrication and other characteristics.

Crossed cylindrical roller bearing catalog

Crossed roller bearing is a special type of bearing with divided inner ring and rotating outer ring. Because the divided inner ring or outer ring is fixed with the cross roller ring after the rollers and spacers are installed to prevent separation from each other, the installation of the cross roller ring is simple. Since the rollers are arranged in a crosswise manner, only one set of cross-roller collars can withstand loads in all directions. Compared with traditional models, the rigidity is increased by 3 to 4 times. At the same time, because the inner ring or outer ring of the crossed roller bearing has a two-part structure, the bearing clearance can be adjusted, and high-precision rotation can be obtained even if preload is applied. over, due to its special structure, it is often used as a spherical bearing in industrial robots.

RB (integrated inner ring, split outer ring) is the basic type of crossed cylindrical roller bearing. The outer ring is divided into two pieces, and the inner ring is an integral structure. It is most suitable for occasions that require inner ring rotation accuracy.

| Part Number | Seal Type | Bore Dia | Outer Dia | Width | Shoulder Height Ds(max) | Ring Material | Roller Material | Weight |

| RB1000110 | Open | 1000 mm | 1250 mm | 110 mm | 1057 mm | Steel | Steel | 360 Kg |

| RB1000110UU | Open | 1000 mm | 1250 mm | 110 mm | 1057 mm | Steel | Steel | 360 Kg |

| RB10016 | Open | 100 mm | 140 mm | 16 mm | 109 mm | Steel | Steel | 0.83 Kg |

| RB10016UU | Sealed | 100 mm | 140 mm | 16 mm | 109 mm | Steel | Steel | 0.83 Kg |

| RB10020 | Open | 100 mm | 150 mm | 20 mm | 113 mm | Steel | Steel | 1.45 Kg |

| RB10020UU | Sealed | 100 mm | 150 mm | 20 mm | 113 mm | Steel | Steel | 1.45 Kg |

| RB11012 | Open | 110 mm | 135 mm | 12 mm | 117 mm | Steel | Steel | 0.4 Kg |

| RB11012UU | Sealed | 110 mm | 135 mm | 12 mm | 117 mm | Steel | Steel | 0.4 Kg |

| RB11015 | Open | 110 mm | 145 mm | 15 mm | 119 mm | Steel | Steel | 0.75 Kg |

| RB11015UU | Sealed | 110 mm | 145 mm | 15 mm | 119 mm | Steel | Steel | 0.75 Kg |

| RB11020 | Open | 110 mm | 160 mm | 20 mm | 120 mm | Steel | Steel | 1.56 Kg |

| RB11020UU | Sealed | 110 mm | 160 mm | 20 mm | 120 mm | Steel | Steel | 1.56 Kg |

| RB12016 | Open | 120 mm | 150 mm | 16 mm | 127 mm | Steel | Steel | 0.72 Kg |

| RB12016UU | Sealed | 120 mm | 150 mm | 16 mm | 127 mm | Steel | Steel | 0.72 Kg |

| RB12025 | Open | 120 mm | 180 mm | 25 mm | 133 mm | Steel | Steel | 2.62 Kg |

| RB12025UU | Sealed | 120 mm | 180 mm | 25 mm | 133 mm | Steel | Steel | 2.62 Kg |

| RB1250110 | Open | 1250 mm | 1500 mm | 110 mm | 1308 mm | Steel | Steel | 440 Kg |

| RB1250110UU | Open | 1250 mm | 1500 mm | 110 mm | 1308 mm | Steel | Steel | 440 Kg |

| RB13015 | Open | 130 mm | 160 mm | 15 mm | 137 mm | Steel | Steel | 0.72 Kg |

| RB13015UU | Sealed | 130 mm | 160 mm | 15 mm | 137 mm | Steel | Steel | 0.72 Kg |

| RB13025 | Open | 130 mm | 190 mm | 25 mm | 143 mm | Steel | Steel | 2.82 Kg |

| RB13025UU | Sealed | 130 mm | 190 mm | 25 mm | 143 mm | Steel | Steel | 2.82 Kg |

| RB14016 | Open | 140 mm | 175 mm | 16 mm | 147 mm | Steel | Steel | 1 Kg |

| RB14016UU | Sealed | 140 mm | 175 mm | 16 mm | 147 mm | Steel | Steel | 1 Kg |

| RB14025 | Open | 140 mm | 200 mm | 25 mm | 154 mm | Steel | Steel | 2.96 Kg |

| RB14025UU | Sealed | 140 mm | 200 mm | 25 mm | 154 mm | Steel | Steel | 2.96 Kg |

| RB15013 | Open | 150 mm | 180 mm | 13 mm | 157 mm | Steel | Steel | 0.68 Kg |

| RB15013UU | Sealed | 150 mm | 180 mm | 13 mm | 157 mm | Steel | Steel | 0.68 Kg |

| RB15025 | Open | 150 mm | 210 mm | 25 mm | 164 mm | Steel | Steel | 3.16 Kg |

| RB15025UU | Sealed | 150 mm | 210 mm | 25 mm | 164 mm | Steel | Steel | 3.16 Kg |

| RB15030 | Open | 150 mm | 230 mm | 30 mm | 169 mm | Steel | Steel | 5.3 Kg |

| RB15030UU | Sealed | 150 mm | 230 mm | 30 mm | 169 mm | Steel | Steel | 5.3 Kg |

| RB16025 | Open | 160 mm | 220 mm | 25 mm | 173 mm | Steel | Steel | 3.14 Kg |

| RB16025UU | Sealed | 160 mm | 220 mm | 25 mm | 173 mm | Steel | Steel | 3.14 Kg |

| RB17020 | Open | 170 mm | 220 mm | 20 mm | 184 mm | Steel | Steel | 2.21 Kg |

| RB17020UU | Sealed | 170 mm | 220 mm | 20 mm | 184 mm | Steel | Steel | 2.21 Kg |

| RB18025 | Open | 180 mm | 240 mm | 25 mm | 195 mm | Steel | Steel | 3.44 Kg |

| RB18025UU | Sealed | 180 mm | 240 mm | 25 mm | 195 mm | Steel | Steel | 3.44 Kg |

| RB19025 | Open | 190 mm | 240 mm | 25 mm | 202 mm | Steel | Steel | 2.99 Kg |

| RB19025UU | Sealed | 190 mm | 240 mm | 25 mm | 202 mm | Steel | Steel | 2.99 Kg |

| RB20025 | Open | 200 mm | 260 mm | 25 mm | 215 mm | Steel | Steel | 4 Kg |

| RB20025UU | Sealed | 200 mm | 260 mm | 25 mm | 215 mm | Steel | Steel | 4 Kg |

| RB20030 | Open | 200 mm | 280 mm | 30 mm | 221 mm | Steel | Steel | 6.7 Kg |

| RB20035 | Open | 200 mm | 295 mm | 35 mm | 225 mm | Steel | Steel | 9.6 Kg |

| RB2008 | Open | 20 mm | 36 mm | 8 mm | 23.5 mm | Steel | Steel | 0.04 Kg |

| RB2008UU | Sealed | 20 mm | 36 mm | 8 mm | 23.5 mm | Steel | Steel | 0.04 Kg |

| RB22025 | Open | 220 mm | 280 mm | 25 mm | 235 mm | Steel | Steel | 4.1 Kg |

| RB22025UU | Sealed | 220 mm | 280 mm | 25 mm | 235 mm | Steel | Steel | 4.1 Kg |

| RB24025 | Open | 240 mm | 300 mm | 25 mm | 256 mm | Steel | Steel | 4.5 Kg |

| RB24025UU | Sealed | 240 mm | 300 mm | 25 mm | 256 mm | Steel | Steel | 4.5 Kg |

| RB25025 | Open | 250 mm | 310 mm | 25 mm | 265 mm | Steel | Steel | 5 Kg |

| RB25025UU | Sealed | 250 mm | 310 mm | 25 mm | 265 mm | Steel | Steel | 5 Kg |

| RB25030 | Open | 250 mm | 330 mm | 30 mm | 269 mm | Steel | Steel | 8.1 Kg |

| RB25040 | Open | 250 mm | 355 mm | 40 mm | 275 mm | Steel | Steel | 14.8 Kg |

| RB2508 | Open | 25 mm | 41 mm | 8 mm | 28.5 mm | Steel | Steel | 0.05 Kg |

| RB2508UU | Sealed | 25 mm | 41 mm | 8 mm | 28.5 mm | Steel | Steel | 0.05 Kg |

| RB30025 | Open | 300 mm | 360 mm | 25 mm | 315 mm | Steel | Steel | 5.9 Kg |

| RB30025UU | Sealed | 300 mm | 360 mm | 25 mm | 315 mm | Steel | Steel | 5.9 Kg |

| RB30035 | Open | 300 mm | 395 mm | 35 mm | 322 mm | Steel | Steel | 13.4 Kg |

| RB30040 | Open | 300 mm | 405 mm | 40 mm | 326 mm | Steel | Steel | 17.2 Kg |

| RB3010 | Open | 30 mm | 55 mm | 10 mm | 37 mm | Steel | Steel | 0.12 Kg |

| RB3010UU | Sealed | 30 mm | 55 mm | 10 mm | 37 mm | Steel | Steel | 0.12 Kg |

| RB35020 | Open | 350 mm | 400 mm | 20 mm | 363 mm | Steel | Steel | 3.9 Kg |

| RB35020UU | Sealed | 350 mm | 400 mm | 20 mm | 363 mm | Steel | Steel | 3.9 Kg |

| RB3510 | Open | 35 mm | 60 mm | 10 mm | 41 mm | Steel | Steel | 0.13 Kg |

| RB3510UU | Sealed | 35 mm | 60 mm | 10 mm | 41 mm | Steel | Steel | 0.13 Kg |

| RB40035 | Open | 400 mm | 480 mm | 35 mm | 422 mm | Steel | Steel | 14.5 Kg |

| RB40040 | Open | 400 mm | 510 mm | 40 mm | 428 mm | Steel | Steel | 23.5 Kg |

| RB4010 | Open | 40 mm | 65 mm | 10 mm | 46.5 mm | Steel | Steel | 0.16 Kg |

| RB4010UU | Sealed | 40 mm | 65 mm | 10 mm | 46.5 mm | Steel | Steel | 0.16 Kg |

| RB45025 | Open | 450 mm | 500 mm | 25 mm | 464 mm | Steel | Steel | 6.6 Kg |

| RB45025UU | Sealed | 450 mm | 500 mm | 25 mm | 464 mm | Steel | Steel | 6.6 Kg |

| RB4510 | Open | 45 mm | 70 mm | 10 mm | 51 mm | Steel | Steel | 0.17 Kg |

| RB4510UU | Sealed | 45 mm | 70 mm | 10 mm | 51 mm | Steel | Steel | 0.17 Kg |

| RB50025 | Open | 500 mm | 550 mm | 25 mm | 514 mm | Steel | Steel | 7.3 Kg |

| RB50025UU | Sealed | 500 mm | 550 mm | 25 mm | 514 mm | Steel | Steel | 7.3 Kg |

| RB50040 | Open | 500 mm | 600 mm | 40 mm | 526 mm | Steel | Steel | 26 Kg |

| RB50040UU | Sealed | 500 mm | 600 mm | 40 mm | 526 mm | Steel | Steel | 26 Kg |

| RB50050 | Open | 500 mm | 625 mm | 50 mm | 536 mm | Steel | Steel | 41.7 Kg |

| RB50050UU | Sealed | 500 mm | 625 mm | 50 mm | 536 mm | Steel | Steel | 41.7 Kg |

| RB5013 | Open | 50 mm | 80 mm | 13 mm | 57 mm | Steel | Steel | 0.27 Kg |

| RB5013UU | Sealed | 50 mm | 80 mm | 13 mm | 57 mm | Steel | Steel | 0.27 Kg |

| RB60040 | Open | 600 mm | 700 mm | 40 mm | 627 mm | Steel | Steel | 29 Kg |

| RB6013 | Open | 60 mm | 90 mm | 13 mm | 67 mm | Steel | Steel | 0.3 Kg |

| RB6013UU | Sealed | 60 mm | 90 mm | 13 mm | 67 mm | Steel | Steel | 0.3 Kg |

| RB70045 | Open | 700 mm | 815 mm | 45 mm | 731 mm | Steel | Steel | 46 Kg |

| RB7013 | Open | 70 mm | 100 mm | 13 mm | 77 mm | Steel | Steel | 0.35 Kg |

| RB7013UU | Sealed | 70 mm | 100 mm | 13 mm | 77 mm | Steel | Steel | 0.35 Kg |

| RB80070 | Open | 800 mm | 950 mm | 70 mm | 836 mm | Steel | Steel | 105 Kg |

| RB8016 | Open | 80 mm | 120 mm | 16 mm | 88 mm | Steel | Steel | 0.7 Kg |

| RB8016UU | Sealed | 80 mm | 120 mm | 16 mm | 88 mm | Steel | Steel | 0.7 Kg |

| RB90070 | Open | 900 mm | 1050 mm | 70 mm | 937 mm | Steel | Steel | 120 Kg |

| RB90070UU | Open | 900 mm | 1050 mm | 70 mm | 937 mm | Steel | Steel | 120 Kg |

| RB9016 | Open | 90 mm | 130 mm | 16 mm | 98 mm | Steel | Steel | 0.75 Kg |

| RB9016UU | Sealed | 90 mm | 130 mm | 16 mm | 98 mm | Steel | Steel | 0.75 Kg |

RE is also the basic type of crossed roller bearing. The overall dimensions are the same as the RB type, but the structure is the outer ring as a whole and the inner ring is divided into two pieces. It is most suitable for occasions that require the rotation accuracy of the outer ring.

| Part Number | Seal Type | Bore Dia | Outer Dia | Width | Ring Material | Roller Material | Temperature Range | Weight |

| RE10016 | Open | 100 mm | 140 mm | 16 mm | Steel | Steel | 0 -230 °F | 0.83 Kg |

| RE10016UU | Sealed | 100 mm | 140 mm | 16 mm | Steel | Steel | 0 -230 °F | 0.83 Kg |

| RE10020 | Open | 100 mm | 150 mm | 20 mm | Steel | Steel | 0 -230 °F | 1.45 Kg |

| RE10020UU | Sealed | 100 mm | 150 mm | 20 mm | Steel | Steel | 0 -230 °F | 1.45 Kg |

| RE11012 | Open | 110 mm | 135 mm | 12 mm | Steel | Steel | 0 -230 °F | 0.4 Kg |

| RE11012UU | Sealed | 110 mm | 135 mm | 12 mm | Steel | Steel | 0 -230 °F | 0.4 Kg |

| RE11015 | Open | 110 mm | 145 mm | 15 mm | Steel | Steel | 0 -230 °F | 0.75 Kg |

| RE11015UU | Sealed | 110 mm | 145 mm | 15 mm | Steel | Steel | 0 -230 °F | 0.75 Kg |

| RE11020 | Open | 110 mm | 160 mm | 20 mm | Steel | Steel | 0 -230 °F | 1.56 Kg |

| RE11020UU | Sealed | 110 mm | 160 mm | 20 mm | Steel | Steel | 0 -230 °F | 1.56 Kg |

| RE12016 | Open | 120 mm | 150 mm | 16 mm | Steel | Steel | 0 -230 °F | 0.72 Kg |

| RE12016UU | Sealed | 120 mm | 150 mm | 16 mm | Steel | Steel | 0 -230 °F | 0.72 Kg |

| RE12025 | Open | 120 mm | 180 mm | 25 mm | Steel | Steel | 0 -230 °F | 2.62 Kg |

| RE12025UU | Sealed | 120 mm | 180 mm | 25 mm | Steel | Steel | 0 -230 °F | 2.62 Kg |

| RE13015 | Open | 130 mm | 160 mm | 15 mm | Steel | Steel | 0 -230 °F | 0.72 Kg |

| RE13015UU | Sealed | 130 mm | 160 mm | 15 mm | Steel | Steel | 0 -230 °F | 0.72 Kg |

| RE13025 | Open | 130 mm | 190 mm | 25 mm | Steel | Steel | 0 -230 °F | 2.82 Kg |

| RE13025UU | Sealed | 130 mm | 190 mm | 25 mm | Steel | Steel | 0 -230 °F | 2.82 Kg |

| RE14016 | Open | 140 mm | 175 mm | 16 mm | Steel | Steel | 0 -230 °F | 1 Kg |

| RE14016UU | Sealed | 140 mm | 175 mm | 16 mm | Steel | Steel | 0 -230 °F | 1 Kg |

| RE14025 | Open | 140 mm | 200 mm | 25 mm | Steel | Steel | 0 -230 °F | 2.96 Kg |

| RE14025UU | Sealed | 140 mm | 200 mm | 25 mm | Steel | Steel | 0 -230 °F | 2.96 Kg |

| RE15013 | Open | 150 mm | 180 mm | 13 mm | Steel | Steel | 0 -230 °F | 0.68 Kg |

| RE15013UU | Sealed | 150 mm | 180 mm | 13 mm | Steel | Steel | 0 -230 °F | 0.68 Kg |

| RE15025 | Open | 150 mm | 210 mm | 25 mm | Steel | Steel | 0 -230 °F | 3.16 Kg |

| RE15025UU | Sealed | 150 mm | 210 mm | 25 mm | Steel | Steel | 0 -230 °F | 3.16 Kg |

| RE15030 | Open | 150 mm | 230 mm | 30 mm | Steel | Steel | 0 -230 °F | 5.3 Kg |

| RE15030UU | Sealed | 150 mm | 230 mm | 30 mm | Steel | Steel | 0 -230 °F | 5.3 Kg |

| RE16025 | Open | 160 mm | 220 mm | 25 mm | Steel | Steel | 0 -230 °F | 3.14 Kg |

| RE16025UU | Sealed | 160 mm | 220 mm | 25 mm | Steel | Steel | 0 -230 °F | 3.14 Kg |

| RE17020 | Open | 170 mm | 220 mm | 20 mm | Steel | Steel | 0 -230 °F | 2.21 Kg |

| RE17020UU | Sealed | 170 mm | 220 mm | 20 mm | Steel | Steel | 0 -230 °F | 2.21 Kg |

| RE18025 | Open | 180 mm | 240 mm | 25 mm | Steel | Steel | 0 -230 °F | 3.44 Kg |

| RE18025UU | Sealed | 180 mm | 240 mm | 25 mm | Steel | Steel | 0 -230 °F | 3.44 Kg |

| RE19025 | Open | 190 mm | 240 mm | 25 mm | Steel | Steel | 0 -230 °F | 2.99 Kg |

| RE19025UU | Sealed | 190 mm | 240 mm | 25 mm | Steel | Steel | 0 -230 °F | 2.99 Kg |

| RE20025 | Open | 200 mm | 260 mm | 25 mm | Steel | Steel | 0 -230 °F | 4 Kg |

| RE20025UU | Sealed | 200 mm | 260 mm | 25 mm | Steel | Steel | 0 -230 °F | 4 Kg |

| RE20030 | Open | 200 mm | 280 mm | 30 mm | Steel | Steel | 0 -230 °F | 6.7 Kg |

| RE20030UU | Sealed | 200 mm | 280 mm | 30 mm | Steel | Steel | 0 -230 °F | 6.7 Kg |

| RE20035 | Open | 200 mm | 295 mm | 35 mm | Steel | Steel | 0 -230 °F | 9.6 Kg |

| RE20035UU | Sealed | 200 mm | 295 mm | 35 mm | Steel | Steel | 0 -230 °F | 9.6 Kg |

| RE2008 | Open | 20 mm | 36 mm | 8 mm | Steel | Steel | 0 -230 °F | 0.04 Kg |

| RE2008UU | Sealed | 20 mm | 36 mm | 8 mm | Steel | Steel | 0 -230 °F | 0.04 Kg |

| RE22025 | Open | 220 mm | 280 mm | 25 mm | Steel | Steel | 0 -230 °F | 4.1 Kg |

| RE22025UU | Sealed | 220 mm | 280 mm | 25 mm | Steel | Steel | 0 -230 °F | 4.1 Kg |

| RE24025 | Open | 240 mm | 300 mm | 25 mm | Steel | Steel | 0 -230 °F | 4.5 Kg |

| RE24025UU | Sealed | 240 mm | 300 mm | 25 mm | Steel | Steel | 0 -230 °F | 4.5 Kg |

| RE25025 | Open | 250 mm | 310 mm | 25 mm | Steel | Steel | 0 -230 °F | 5 Kg |

| RE25025UU | Sealed | 250 mm | 310 mm | 25 mm | Steel | Steel | 0 -230 °F | 5 Kg |

| RE25030 | Open | 250 mm | 330 mm | 30 mm | Steel | Steel | 0 -230 °F | 8.1 Kg |

| RE25030UU | Sealed | 250 mm | 330 mm | 30 mm | Steel | Steel | 0 -230 °F | 8.1 Kg |

| RE25040 | Open | 250 mm | 355 mm | 40 mm | Steel | Steel | 0 -230 °F | 14.8 Kg |

| RE25040UU | Sealed | 250 mm | 355 mm | 40 mm | Steel | Steel | 0 -230 °F | 14.8 Kg |

| RE2508 | Open | 25 mm | 41 mm | 8 mm | Steel | Steel | 0 -230 °F | 0.05 Kg |

| RE2508UU | Sealed | 25 mm | 41 mm | 8 mm | Steel | Steel | 0 -230 °F | 0.05 Kg |

| RE30025 | Open | 300 mm | 360 mm | 25 mm | Steel | Steel | 0 -230 °F | 5.9 Kg |

| RE30025UU | Sealed | 300 mm | 360 mm | 25 mm | Steel | Steel | 0 -230 °F | 5.9 Kg |

| RE30035 | Open | 300 mm | 395 mm | 35 mm | Steel | Steel | 0 -230 °F | 13.4 Kg |

| RE30035UU | Sealed | 300 mm | 395 mm | 35 mm | Steel | Steel | 0 -230 °F | 13.4 Kg |

| RE30040 | Open | 300 mm | 405 mm | 40 mm | Steel | Steel | 0 -230 °F | 17.2 Kg |

| RE30040UU | Sealed | 300 mm | 405 mm | 40 mm | Steel | Steel | 0 -230 °F | 17.2 Kg |

| RE3010 | Open | 30 mm | 55 mm | 10 mm | Steel | Steel | 0 -230 °F | 0.12 Kg |

| RE3010UU | Sealed | 30 mm | 55 mm | 10 mm | Steel | Steel | 0 -230 °F | 0.12 Kg |

| RE35020 | Open | 350 mm | 400 mm | 20 mm | Steel | Steel | 0 -230 °F | 3.9 Kg |

| RE35020UU | Sealed | 350 mm | 400 mm | 20 mm | Steel | Steel | 0 -230 °F | 3.9 Kg |

| RE3510 | Open | 35 mm | 60 mm | 10 mm | Steel | Steel | 0 -230 °F | 0.13 Kg |

| RE3510UU | Sealed | 35 mm | 60 mm | 10 mm | Steel | Steel | 0 -230 °F | 0.13 Kg |

| RE40035 | Open | 400 mm | 480 mm | 35 mm | Steel | Steel | 0 -230 °F | 14.5 Kg |

| RE40035UU | Sealed | 400 mm | 480 mm | 35 mm | Steel | Steel | 0 -230 °F | 14.5 Kg |

| RE40040 | Open | 400 mm | 510 mm | 40 mm | Steel | Steel | 0 -230 °F | 23.5 Kg |

| RE40040UU | Sealed | 400 mm | 510 mm | 40 mm | Steel | Steel | 0 -230 °F | 23.5 Kg |

| RE4010 | Open | 40 mm | 65 mm | 10 mm | Steel | Steel | 0 -230 °F | 0.16 Kg |

| RE4010UU | Sealed | 40 mm | 65 mm | 10 mm | Steel | Steel | 0 -230 °F | 0.16 Kg |

| RE45025 | Open | 450 mm | 500 mm | 25 mm | Steel | Steel | 0 -230 °F | 6.6 Kg |

| RE45025UU | Sealed | 450 mm | 500 mm | 25 mm | Steel | Steel | 0 -230 °F | 6.6 Kg |

| RE4510 | Open | 45 mm | 70 mm | 10 mm | Steel | Steel | 0 -230 °F | 0.17 Kg |

| RE4510UU | Sealed | 45 mm | 70 mm | 10 mm | Steel | Steel | 0 -230 °F | 0.17 Kg |

| RE50025 | Open | 500 mm | 550 mm | 25 mm | Steel | Steel | 0 -230 °F | 7.3 Kg |

| RE50025UU | Sealed | 500 mm | 550 mm | 25 mm | Steel | Steel | 0 -230 °F | 7.3 Kg |

| RE50040 | Open | 500 mm | 600 mm | 40 mm | Steel | Steel | 0 -230 °F | 26 Kg |

| RE50040UU | Sealed | 500 mm | 600 mm | 40 mm | Steel | Steel | 0 -230 °F | 26 Kg |

| RE50050 | Open | 500 mm | 625 mm | 50 mm | Steel | Steel | 0 -230 °F | 41.7 Kg |

| RE50050UU | Sealed | 500 mm | 625 mm | 50 mm | Steel | Steel | 0 -230 °F | 41.7 Kg |

| RE5013 | Open | 50 mm | 80 mm | 13 mm | Steel | Steel | 0 -230 °F | 0.27 Kg |

| RE5013UU | Sealed | 50 mm | 80 mm | 13 mm | Steel | Steel | 0 -230 °F | 0.27 Kg |

| RE60040 | Open | 600 mm | 700 mm | 40 mm | Steel | Steel | 0 -230 °F | 29 Kg |

| RE60040UU | Sealed | 600 mm | 700 mm | 40 mm | Steel | Steel | 0 -230 °F | 29 Kg |

| RE6013 | Open | 60 mm | 90 mm | 13 mm | Steel | Steel | 0 -230 °F | 0.3 Kg |

| RE6013UU | Sealed | 60 mm | 90 mm | 13 mm | Steel | Steel | 0 -230 °F | 0.3 Kg |

| RE7013 | Open | 70 mm | 100 mm | 13 mm | Steel | Steel | 0 -230 °F | 0.35 Kg |

| RE7013UU | Sealed | 70 mm | 100 mm | 13 mm | Steel | Steel | 0 -230 °F | 0.35 Kg |

| RE8016 | Open | 80 mm | 120 mm | 16 mm | Steel | Steel | 0 -230 °F | 0.7 Kg |

| RE8016UU | Sealed | 80 mm | 120 mm | 16 mm | Steel | Steel | 0 -230 °F | 0.7 Kg |

| RE9016 | Open | 90 mm | 130 mm | 16 mm | Steel | Steel | 0 -230 °F | 0.75 Kg |

| RE9016UU | Sealed | 90 mm | 130 mm | 16 mm | Steel | Steel | 0 -230 °F | 0.75 Kg |

RA is the basic type of crossed roller bearing. The outer ring is divided into two pieces, and the inner ring is an integral structure. It is most suitable for occasions that require the rotation accuracy of the inner ring. This model is a compact model that reduces the thickness of the inner and outer rings of the RB model to the limit. It is most suitable for parts with light weight and compact design, such as rotating parts of robots and manipulators.

| Part Number | Seal Type | Bore Dia | Outer Dia | Width | Ring Material | Roller Material | Weight |

| RA10008 | Open | 100 mm | 116 mm | 8 mm | Steel | Steel | 0.14 Kg |

| RA10008C | Open | 100 mm | 116 mm | 8 mm | Steel | Steel | 0.14 Kg |

| RA10008CUU | Sealed | 100 mm | 116 mm | 8 mm | Steel | Steel | 0.14 Kg |

| RA10008UU | Sealed | 100 mm | 116 mm | 8 mm | Steel | Steel | 0.14 Kg |

| RA11008 | Open | 110 mm | 126 mm | 8 mm | Steel | Steel | 0.15 Kg |

| RA11008C | Open | 110 mm | 126 mm | 8 mm | Steel | Steel | 0.15 Kg |

| RA11008CUU | Sealed | 110 mm | 126 mm | 8 mm | Steel | Steel | 0.15 Kg |

| RA11008UU | Sealed | 110 mm | 126 mm | 8 mm | Steel | Steel | 0.15 Kg |

| RA12008 | Open | 120 mm | 136 mm | 8 mm | Steel | Steel | 0.17 Kg |

| RA12008C | Open | 120 mm | 136 mm | 8 mm | Steel | Steel | 0.17 Kg |

| RA12008CUU | Sealed | 120 mm | 136 mm | 8 mm | Steel | Steel | 0.17 Kg |

| RA12008UU | Sealed | 120 mm | 136 mm | 8 mm | Steel | Steel | 0.17 Kg |

| RA13008 | Open | 130 mm | 146 mm | 8 mm | Steel | Steel | 0.18 Kg |

| RA13008C | Open | 130 mm | 146 mm | 8 mm | Steel | Steel | 0.18 Kg |

| RA13008CUU | Sealed | 130 mm | 146 mm | 8 mm | Steel | Steel | 0.18 Kg |

| RA13008UU | Sealed | 130 mm | 146 mm | 8 mm | Steel | Steel | 0.18 Kg |

| RA14008 | Open | 140 mm | 156 mm | 8 mm | Steel | Steel | 0.19 Kg |

| RA14008C | Open | 140 mm | 156 mm | 8 mm | Steel | Steel | 0.19 Kg |

| RA14008CUU | Sealed | 140 mm | 156 mm | 8 mm | Steel | Steel | 0.19 Kg |

| RA14008UU | Sealed | 140 mm | 156 mm | 8 mm | Steel | Steel | 0.19 Kg |

| RA15008 | Open | 150 mm | 166 mm | 8 mm | Steel | Steel | 0.2 Kg |

| RA15008C | Open | 150 mm | 166 mm | 8 mm | Steel | Steel | 0.2 Kg |

| RA15008CUU | Sealed | 150 mm | 166 mm | 8 mm | Steel | Steel | 0.2 Kg |

| RA15008UU | Sealed | 150 mm | 166 mm | 8 mm | Steel | Steel | 0.2 Kg |

| RA16013 | Open | 160 mm | 186 mm | 13 mm | Steel | Steel | 0.59 Kg |

| RA16013C | Open | 160 mm | 186 mm | 13 mm | Steel | Steel | 0.59 Kg |

| RA16013CUU | Sealed | 160 mm | 186 mm | 13 mm | Steel | Steel | 0.59 Kg |

| RA16013UU | Sealed | 160 mm | 186 mm | 13 mm | Steel | Steel | 0.59 Kg |

| RA17013 | Open | 170 mm | 196 mm | 13 mm | Steel | Steel | 0.64 Kg |

| RA17013C | Open | 170 mm | 196 mm | 13 mm | Steel | Steel | 0.64 Kg |

| RA17013CUU | Sealed | 170 mm | 196 mm | 13 mm | Steel | Steel | 0.64 Kg |

| RA17013UU | Sealed | 170 mm | 196 mm | 13 mm | Steel | Steel | 0.64 Kg |

| RA18013 | Open | 180 mm | 206 mm | 13 mm | Steel | Steel | 0.68 Kg |

| RA18013C | Open | 180 mm | 206 mm | 13 mm | Steel | Steel | 0.68 Kg |

| RA18013CUU | Sealed | 180 mm | 206 mm | 13 mm | Steel | Steel | 0.68 Kg |

| RA18013UU | Sealed | 180 mm | 206 mm | 13 mm | Steel | Steel | 0.68 Kg |

| RA19013 | Open | 190 mm | 216 mm | 13 mm | Steel | Steel | 0.69 Kg |

| RA19013C | Open | 190 mm | 216 mm | 13 mm | Steel | Steel | 0.69 Kg |

| RA19013CUU | Sealed | 190 mm | 216 mm | 13 mm | Steel | Steel | 0.69 Kg |

| RA19013UU | Sealed | 190 mm | 216 mm | 13 mm | Steel | Steel | 0.69 Kg |

| RA20013 | Open | 200 mm | 226 mm | 13 mm | Steel | Steel | 0.71 Kg |

| RA20013C | Open | 200 mm | 226 mm | 13 mm | Steel | Steel | 0.71 Kg |

| RA20013CUU | Sealed | 200 mm | 226 mm | 13 mm | Steel | Steel | 0.71 Kg |

| RA20013UU | Sealed | 200 mm | 226 mm | 13 mm | Steel | Steel | 0.71 Kg |

| RA5008 | Open | 50 mm | 66 mm | 8 mm | Steel | Steel | 0.08 Kg |

| RA5008C | Open | 50 mm | 66 mm | 8 mm | Steel | Steel | 0.08 Kg |

| RA5008CUU | Sealed | 50 mm | 66 mm | 8 mm | Steel | Steel | 0.08 Kg |

| RA5008UU | Sealed | 50 mm | 66 mm | 8 mm | Steel | Steel | 0.08 Kg |

| RA6008 | Open | 60 mm | 76 mm | 8 mm | Steel | Steel | 0.09 Kg |

| RA6008C | Open | 60 mm | 76 mm | 8 mm | Steel | Steel | 0.09 Kg |

| RA6008CUU | Sealed | 60 mm | 76 mm | 8 mm | Steel | Steel | 0.09 Kg |

| RA6008UU | Sealed | 60 mm | 76 mm | 8 mm | Steel | Steel | 0.09 Kg |

| RA7008 | Open | 70 mm | 86 mm | 8 mm | Steel | Steel | 0.1 Kg |

| RA7008C | Open | 70 mm | 86 mm | 8 mm | Steel | Steel | 0.1 Kg |

| RA7008CUU | Sealed | 70 mm | 86 mm | 8 mm | Steel | Steel | 0.1 Kg |

| RA7008UU | Sealed | 70 mm | 86 mm | 8 mm | Steel | Steel | 0.1 Kg |

| RA8008 | Open | 80 mm | 96 mm | 8 mm | Steel | Steel | 0.11 Kg |

| RA8008C | Open | 80 mm | 96 mm | 8 mm | Steel | Steel | 0.11 Kg |

| RA8008CUU | Sealed | 80 mm | 96 mm | 8 mm | Steel | Steel | 0.11 Kg |

| RA8008UU | Sealed | 80 mm | 96 mm | 8 mm | Steel | Steel | 0.11 Kg |

| RA9008 | Open | 90 mm | 106 mm | 8 mm | Steel | Steel | 0.12 Kg |

| RA9008C | Open | 90 mm | 106 mm | 8 mm | Steel | Steel | 0.12 Kg |

| RA9008CUU | Sealed | 90 mm | 106 mm | 8 mm | Steel | Steel | 0.12 Kg |

| RA9008UU | Sealed | 90 mm | 106 mm | 8 mm | Steel | Steel | 0.12 Kg |

RA-C

The main dimensions are the same as RA. Since this model has a notch structure in the outer ring, the outer ring also has high rigidity, so it can also be used in applications where the outer ring rotates.

CRBH:

Its structure is an integral inner and outer ring. It adopts an ultra-thin design and has no mounting holes in the inner and outer rings. It requires flange and support base to be fixed during installation.

| Part Number | Seal Type | Bore Dia | Outer Dia | Width | Ring Material | Weight |

| CRBH30025A | Open | 300 mm | 360 mm | 25 mm | Steel | 5.29 Kg |

| CRBH30025AUU | Sealed | 300 mm | 360 mm | 25 mm | Steel | 5.29 Kg |

| CRBHV10020A | Open | 100 mm | 150 mm | 20 mm | Steel | 1.45 Kg |

| CRBHV10020AUU | Sealed | 100 mm | 150 mm | 20 mm | Steel | 1.45 Kg |

| CRBHV11020A | Open | 110 mm | 160 mm | 20 mm | Steel | 1.56 Kg |

| CRBHV11020AUU | Sealed | 110 mm | 160 mm | 20 mm | Steel | 1.56 Kg |

| CRBHV12025A | Open | 120 mm | 180 mm | 25 mm | Steel | 2.62 Kg |

| CRBHV12025AUU | Sealed | 120 mm | 180 mm | 25 mm | Steel | 2.62 Kg |

| CRBHV13025A | Open | 130 mm | 190 mm | 25 mm | Steel | 2.82 Kg |

| CRBHV13025AUU | Sealed | 130 mm | 190 mm | 25 mm | Steel | 2.82 Kg |

| CRBHV14025A | Open | 140 mm | 200 mm | 25 mm | Steel | 2.96 Kg |

| CRBHV14025AUU | Sealed | 140 mm | 200 mm | 25 mm | Steel | 2.96 Kg |

| CRBHV15025A | Open | 150 mm | 210 mm | 25 mm | Steel | 3.16 Kg |

| CRBHV15025AUU | Sealed | 150 mm | 210 mm | 25 mm | Steel | 3.16 Kg |

| CRBHV20025A | Open | 200 mm | 260 mm | 25 mm | Steel | 4 Kg |

| CRBHV20025AUU | Sealed | 200 mm | 260 mm | 25 mm | Steel | 4 Kg |

| CRBHV208A | Open | 20 mm | 36 mm | 8 mm | Steel | 0.04 Kg |

| CRBHV208AUU | Sealed | 20 mm | 36 mm | 8 mm | Steel | 0.04 Kg |

| CRBHV25025A | Open | 250 mm | 310 mm | 25 mm | Steel | 4.97 Kg |

| CRBHV25025AUU | Sealed | 250 mm | 310 mm | 25 mm | Steel | 4.97 Kg |

| CRBHV258A | Open | 25 mm | 41 mm | 8 mm | Steel | 0.05 Kg |

| CRBHV258AUU | Sealed | 25 mm | 41 mm | 8 mm | Steel | 0.05 Kg |

| CRBHV3010A | Open | 30 mm | 55 mm | 10 mm | Steel | 0.12 Kg |

| CRBHV3010AUU | Sealed | 30 mm | 55 mm | 10 mm | Steel | 0.12 Kg |

| CRBHV3510A | Open | 35 mm | 60 mm | 10 mm | Steel | 0.13 Kg |

| CRBHV3510AUU | Sealed | 35 mm | 60 mm | 10 mm | Steel | 0.13 Kg |

| CRBHV4010A | Open | 40 mm | 65 mm | 10 mm | Steel | 0.15 Kg |

| CRBHV4010AUU | Sealed | 40 mm | 65 mm | 10 mm | Steel | 0.15 Kg |

| CRBHV4510A | Open | 45 mm | 70 mm | 10 mm | Steel | 0.16 Kg |

| CRBHV4510AUU | Sealed | 45 mm | 70 mm | 10 mm | Steel | 0.16 Kg |

| CRBHV5013A | Open | 50 mm | 80 mm | 13 mm | Steel | 0.29 Kg |

| CRBHV5013AUU | Sealed | 50 mm | 80 mm | 13 mm | Steel | 0.29 Kg |

| CRBHV6013A | Open | 60 mm | 90 mm | 13 mm | Steel | 0.33 Kg |

| CRBHV6013AUU | Sealed | 60 mm | 90 mm | 13 mm | Steel | 0.33 Kg |

| CRBHV7013A | Open | 70 mm | 100 mm | 13 mm | Steel | 0.38 Kg |

| CRBHV7013AUU | Sealed | 70 mm | 100 mm | 13 mm | Steel | 0.38 Kg |

| CRBHV8016A | Open | 80 mm | 120 mm | 16 mm | Steel | 0.74 Kg |

| CRBHV8016AUU | Sealed | 80 mm | 120 mm | 16 mm | Steel | 0.74 Kg |

| CRBHV9016A | Open | 90 mm | 130 mm | 16 mm | Steel | 0.81 Kg |

| CRBHV9016AUU | Sealed | 90 mm | 130 mm | 16 mm | Steel | 0.81 Kg |

RU:

This series (integrated inner and outer rings, with mounting holes) does not require fixing flanges and support seats during installation because the outer ring and inner ring have mounting holes. In addition, since the outer ring and inner ring are both integral structures, installation has almost no impact on performance, so stable rotation accuracy and torque can be obtained, which is suitable for situations where the outer ring and inner ring rotate.

| Part Number | Seal Type | Bore Dia | Outer Dia | Width | Ring Material | Weight |

| RU124 | Open | 80 mm | 165 mm | 22 mm | Steel | 2.6 Kg |

| RU124UU | Sealed | 80 mm | 165 mm | 22 mm | Steel | 2.6 Kg |

| RU148 | Open | 90 mm | 210 mm | 25 mm | Steel | 4.9 Kg |

| RU148UU | Sealed | 90 mm | 210 mm | 25 mm | Steel | 4.9 Kg |

| RU178 | Open | 115 mm | 240 mm | 28 mm | Steel | 6.8 Kg |

| RU178UU | Sealed | 115 mm | 240 mm | 28 mm | Steel | 6.8 Kg |

| RU228 | Open | 160 mm | 295 mm | 35 mm | Steel | 11.4 Kg |

| RU228UU | Sealed | 160 mm | 295 mm | 35 mm | Steel | 11.4 Kg |

| RU297 | Open | 210 mm | 380 mm | 40 mm | Steel | 21.3 Kg |

| RU297UU | Sealed | 210 mm | 380 mm | 40 mm | Steel | 21.3 Kg |

| RU42 | Open | 20 mm | 70 mm | 12 mm | Steel | 0.29 Kg |

| RU42UU | Sealed | 20 mm | 70 mm | 12 mm | Steel | 0.31 Kg |

| RU445 | Open | 350 mm | 540 mm | 45 mm | Steel | 35.4 Kg |

| RU445UU | Sealed | 350 mm | 540 mm | 45 mm | Steel | 35.4 Kg |

| RU66 | Open | 35 mm | 95 mm | 15 mm | Steel | 0.62 Kg |

| RU66UU | Sealed | 35 mm | 95 mm | 15 mm | Steel | 0.62 Kg |

| RU85 | Open | 55 mm | 120 mm | 15 mm | Steel | 1 Kg |

| RU85UU | Sealed | 55 mm | 120 mm | 15 mm | Steel | 1 Kg |

SX:

Its structure is similar to that of the RB series. The structure is an integral inner ring and a separate outer ring. Due to the ultra-thin design, there are no mounting holes in the outer and inner rings. The flange and support base are required for installation. It is suitable for the inner ring. Applications with high rotational accuracy.

| Part Number | Bore Dia | Outer Dia | Width | Height(H) | Running Accuracy Radial | Weight |

| SX0118/500 | 500 mm | 620 mm | 56 mm | 56 mm | 0.04 mm | 42.7 Kg |

| SX011814-A | 70 mm | 90 mm | 10 mm | 10 mm | 0.01 mm | 0.25 Kg |

| SX011818-A | 90 mm | 115 mm | 13 mm | 13 mm | 0.01 mm | 0.354 Kg |

| SX011820-A | 100 mm | 125 mm | 13 mm | 13 mm | 0.01 mm | 0.402 Kg |

| SX011824-A | 120 mm | 150 mm | 16 mm | 16 mm | 0.01 mm | 0.698 Kg |

| SX011828-A | 140 mm | 175 mm | 18 mm | 18 mm | 0.015 mm | 1.062 Kg |

| SX011832-A | 160 mm | 200 mm | 20 mm | 20 mm | 0.015 mm | 1.581 Kg |

| SX011836-A | 180 mm | 225 mm | 22 mm | 22 mm | 0.015 mm | 2.22 Kg |

| SX011840-A | 200 mm | 250 mm | 24 mm | 24 mm | 0.015 mm | 2.957 Kg |

| SX011848-A | 240 mm | 300 mm | 28 mm | 28 mm | 0.02 mm | 4.96 Kg |

| SX011860 | 300 mm | 380 mm | 38 mm | 38 mm | 0.02 mm | 11.6 Kg |

| SX011868 | 340 mm | 420 mm | 38 mm | 38 mm | 0.025 mm | 12.92 Kg |

| SX011880 | 400 mm | 500 mm | 46 mm | 46 mm | 0.03 mm | 23.221 Kg |

Choosing the right crossed roller bearing

There are various types and sizes of crossed roller bearings. How to choose the appropriate model and structure is a problem that most customers who use crossed roller bearings are confused about. Well, we know the tips and factors to consider when choosing the right crossed roller bearing.

Structure

As a widely used bearing product, crossed roller bearings also have many types. According to the rolling element structure, crossed roller bearings can be divided into cylindrical roller bearings and tapered roller bearings. When the equipment needs to bear thrust load, Thrust bearings can be used; ball bearings are usually used when the equipment needs to run at high speed; roller bearings can be used when the equipment needs to bear radial loads.

In addition, crossed roller bearings with the same size and appearance also have a variety of structural types, including split outer ring type (RB/RA), split inner ring type (RE), and integral structure (RU/RBH). The key depends on whether the part of the bearing that is driven to rotate needs to be installed on the inner ring or the outer ring of the bearing. If the outer ring needs to rotate, the inner ring split type is used; similarly, when the inner ring needs to rotate, the outer ring split type must be used. If there are higher requirements for the rotation accuracy of the inner and outer rings of the bearing, the integral structure of the inner and outer rings is suitable. of bearings. It is also necessary to consider the arrangement of the bearings, the ease of installation and disassembly, the space allowed for the bearings, the size of the bearings and the marketability of the bearings, etc. to determine the structure of the crossed roller bearing.

Dimension

According to the required installation space of the bearing equipment, determine the required bearing size and leave sufficient space for the installation of the bearing. The overall dimensions are important parameters of crossed roller bearings. The dimensions of the bearings include the inner and outer diameters and the overall dimensions. When purchasing bearings, the size of the shaft is usually determined first, and then the bearing is selected based on the size of the shaft.

Speed

Different types of bearings have different limit speeds. The limit speed of the bearing will be affected by factors such as size, structure, type, etc. For equipment with high speed requirements, when the speed of the bearing exceeds its own limit, the bearing temperature will appear. If it is too high, the lubricant will dry up too quickly and the bearing will get stuck. Bearings lubricated with lubricating oil will have a higher limit speed.

Accuracy and clearance

The accuracy and clearance of crossed roller bearings are the core of crossed roller bearings. The positive and negative travel of the bearing can affect factors such as the rigidity, noise, life and speed of the crossed rollers. When the working clearance is negative, the fatigue life of the bearing is long, but as the negative clearance increases, the fatigue clearance decreases significantly. But it can greatly improve the rigidity of the bearing and reduce the noise of the bearing. Accuracy and clearance, the rigidity, noise, life and speed of crossed roller bearings, are all affected by the positive and negative clearance of the bearing.

Loading

When choosing which cross roller to use, you must understand whether it can withstand the load imposed by the equipment, and determine whether it is suitable based on the load-bearing capacity requirements of the equipment design and the rated load of the corresponding bearings. The load capacity of the bearing is one of the important bearing selection criteria. When the bearing needs to bear radial load, you can choose a cylindrical roller bearing, a needle roller bearing or a deep groove ball bearing; when the bearing needs to bear a smaller shaft When bearings need to bear radial loads, you can choose thrust ball bearings; when bearings need to bear larger axial loads, you can choose thrust roller bearings; when bearings need to bear both radial and axial loads, we need to choose crossed rollers bearings or tapered roller bearings.

Correct installation of crossed roller bearings

Whether the fork roller bearing is installed correctly affects accuracy, life, and performance. Therefore, the design and assembly departments must fully study the installation of bearings. It is hoped that the installation will be carried out according to the work standards. When installing bearings, you need to use the correct method and pay attention to some installation problems. The details are as follows:

Installation method

Crossed roller bearings can be divided into two categories in terms of installation methods. One is that both the inner and outer rings have mounting holes. Like a slewing bearing, its installation is relatively simple and is directly connected to the equipment through connecting bolts; the other is There are no mounting holes in the inner and outer rings, mainly through the interference fit between the bearing seat and the pressing flange and the inner diameter of the shaft and the bearing.

The installation method of the bearing varies depending on the bearing structure, fit, and conditions. Generally, because the shaft rotates mostly, the inner ring requires an interference fit. Cylindrical bore bearings are often pressed in with a press or hot-fitted. In the application scenario of the tapered hole, it is directly installed on the tapered shaft and installed with a sleeve. When installed into the shell, there is generally a lot of clearance fit and there is interference in the outer ring. It is usually pressed in with a press, or there is also a shrink fit method of installing after cooling. When dry ice is used as the coolant and shrink fit is installed, moisture in the air will condense on the surface of the bearing. Therefore, appropriate rust prevention measures are required.

Installation precautions

(1) Before installation, open the package. Generally, grease is filled directly. Oil lubrication.

(2) Instrument or high-speed bearings should be washed with clean oil to remove the anti-rust agent coated on the bearings.

(3) Crossed roller bearings that have been filled with grease can be used directly without cleaning.

Crossed roller bearing life

We know that any product has its own lifespan, and the service life of crossed roller bearings will definitely be affected by long-term rotation during use. In order to use it better and last longer, we need to find ways to increase its service life. , so how do we extend the service life of roller bearings? Next, let’s talk about how to extend the service life of roller bearings.

Factors affecting the service life of crossed roller bearings:

1. Number of rollers: When the number of rollers is small (Z=15), the fatigue life of the bearing is very low, only about 540 hours. As the number of rollers increases, the bearing load capacity and fatigue life also increase accordingly. When reaching the maximum value (Z=34), the fatigue life can be increased to about 3879 hours, an increase of about 7 times. However, the number of rollers cannot be increased without limit. At the same time, increasing the number of rollers will also increase the cost and difficulty of manufacturing and installation.

2. Influence of load size: At different speeds, the bearing fatigue life decreases with load changes. As the rotational speed increases, the influence of radial load on bearing life decreases.

3. Influence of rotational speed: Under different radial loads, the bearing fatigue life changes with the rotational speed. As the rotational speed increases, the centrifugal force and contact stress of the bearing increase, resulting in a decrease in fatigue life. At the same time, under different radial loads, the greater the load, the smaller the impact of rotation speed on fatigue life.

Crossed roller bearing life calculation formula

Since crossed roller bearings can carry radial load, axial load and moment at the same time, the equivalent dynamic load should be solved first before calculating the bearing life.

| P: Equivalent dynamic load/N | d: Bearing inner diameter/mm |

| Fr: Radial force/N | D: Bearing outer diameter/mm |

| Fa: axial force/N | X: radial load coefficient |

| M: Moment/N·mm | Y: Axial load coefficient |

The radial load factor X and axial load factor Y can be obtained from the table below.

Finally, the equivalent dynamic load obtained from the solution is substituted into the bearing life calculation formula.

L10: Basic rated life/106rev

P: Equivalent dynamic load/N

C: basic dynamic load rating/N

P: Index, for roller bearings it is 10/3. Under the premise that the bearing speed is known, the bearing life in time can be obtained.

Lh: Basic rated life in time/hour

L10: Basic rated life/106rev

n: Bearing speed/rpm

Extended service life of crossed roller bearings

First, you need to know how to properly install crossed roller bearings. When installing crossed roller bearings, correct installation methods and procedures need to be followed. It is necessary to ensure that the matching accuracy of the bearing and the mounting seat meets the requirements and install it with appropriate mounting force to avoid bearing damage caused by excessive or insufficient mounting force.

Next, it is necessary to lubricate properly during use. When using crossed roller bearings, proper lubrication is required to reduce the friction coefficient and wear of the bearings. It is necessary to select the appropriate lubricant according to different usage scenarios and working conditions, and lubricate according to the correct lubrication method and cycle. At the same time, it is necessary to avoid overloading and excessively high speeds of the crossed roller bearings. This is done to prevent the bearings from being damaged due to excessive loads and excessive speeds.

Remember to perform regular inspections and maintenance. In order to ensure the normal operation of crossed roller bearings and extend their service life, regular inspection and maintenance of the bearings is required. Regularly check the wear and lubrication status of the bearings, and lubricate and replace the bearings as necessary.