Design and Engineering

At the heart of Aubearing is our ability to work with customers to pursue unique designs and applications, and to provide innovative and cost-effective solutions. Drawing on years of application knowledge and precision instrumentation, our engineering staff has decades of hands-on experience covering hundreds of different applications and industries, including medical, robotics, mining equipment, agricultural equipment, automotive, motorcycles, bicycles, engineering Machinery, earth moving equipment, forestry, packaging, water treatment equipment, printing equipment and , enabling them to tailor optimal bearing design and engineering solutions for specific applications.

Together we can manufacture the best bearing for your exacting specifications, often with tolerances measured in millionths of an inch. We invite you to visit our facilities and we welcome the opportunity to visit yours in an effort to provide solutions for your every need.

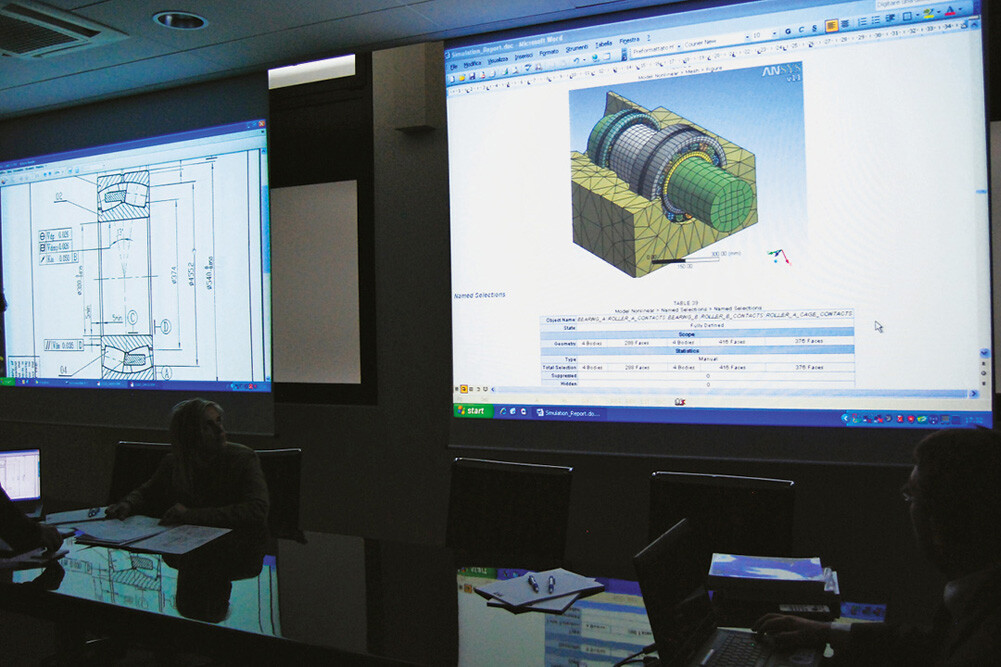

Aubearing's in-house technology lab

Our technical laboratory is equipped with advanced precision instruments and advanced evaluation software (not limited to use including Solid Works, AutoCAD), which can quickly and effectively evaluate bearing applications. The unique “Aubearing Analysis System” evaluates bearings from multiple perspectives. Our design engineers carefully optimize raceway profiles to maximize load ratings, speed limitations and fatigue life. Special consideration has been given to “Design for Manufacture” to ensure optimum residual raceway stress for superior performance. At the same time, many applications are in dusty and contaminated conditions, so bearing seals are also considered to prevent contamination.

Save manufacturing cost

About 70% of bearing manufacturing costs (material costs, tooling costs and assembly costs) are determined by design decisions, while the remaining 30% of costs constitute production decisions such as process planning or machine tool selection. Our goal is to optimize custom bearings to be cost-effective in production, assembly and maintenance while maintaining high quality. Aubearing can recommend bearing size, rolling elements, hardness, gear configuration, etc., and manufactures bearing sizes ranging from 200mm ID to 6,000mm OD to meet your requirements for load, size, rotation and life cycle.

Bearing terms and calculations every design engineer should know

Bearings are found in virtually every rotating assembly in equipment and power transmission applications. They produce smooth rotary motion and reduce friction and wear. When sized and used properly, most bearings will operate for many years without requiring replacement.

Rotary bearing is a broad term that includes plain bearings, hydrostatic and hydrodynamic bearings, magnetic bearings and rolling element bearings. Rolling element bearings can be further broken down by rolling element type — ball, roller and needle roller. Every mechanical design engineer incorporating ball or roller bearings in their assembly should be familiar with calculations for bearing life and bearing load. Knowledge of these basic formulas will help ensure a robust design optimized for long life.

Bearing life

Bearing life (L) is defined as the number of hours the bearing can run at a given constant speed before it displays the first signs of fatigue in the material of either bearing ring or any of the rolling elements.

Bearing rating life (L10) is the life in hours at a specific constant speed that 90% of a group of apparently identical bearings will complete or exceed. Rating life also refers to life for a single bearing associated with 90% reliability. Bearing rating life for bearings that operate at a constant speed can also be expressed in hours and is referred to as L10h. The units for rating life are in millions of revolutions (106rev).

Bearing load ratings

Bearing load is expressed with different terms, each with a unique definition. Static loads refer to loads on a non-rotating bearing.

Basic load rating (CB) is a calculated constant load for radial and angular contact bearings. It is the load that a group of apparently identical bearings can endure for one million revolutions of the inner ring while the outer ring is held stationary. The units for basic load rating are pounds (lb) or Newtons (N).

The basic static load rating (Co) is the radial load on a non-rotating bearing corresponding to a calculated contact stress at the most heavily loaded point of contact between the rolling element and raceway that produces a total permanent deformation of the rolling element and raceway of 0.0001 of the rolling element diameter. The units for basic static load rating are pounds (lb) or Newtons (N).

Static equivalent load (Po) is a calculated static, radial load. It is defined as the load that would cause the same total permanent deformation at the most heavily stressed rolling element and raceway contact as that which occurs under the actual loading condition. The units for static equivalent load rating are pounds (lb) or Newtons (N).

The basic dynamic load rating (C) is the calculated constant radial load that a group of apparently identical bearings with a stationary outer ring can statistically endure one million revolutions of the inner ring. The units for basic dynamic load rating are pounds (lb) or Newtons (N).

Dynamic equivalent load (P) is one of the factors used in bearing life equations. It is a constant, hypothetical radial load, that has the same impact on bearing life as that which occurs under the actual loading condition. The units for dynamic equivalent load rating are pounds (lb) or Newtons (N).

Calculations

Bearing life (L10) can be calculated with the following formula. Variables required are basic dynamic load rating (C) and the dynamic equivalent load of the bearing (P).

L10 = (C/P)3

L10 = rating life (106rev); C = basic dynamic load rating (lb or N); P = dynamic equivalent load (lb or N)

To convert from revolutions to hours divide by the speed (rpm).

L10hrs = (C/P)3 x [(106rev) / (N rpm x 60min/hr)] = 16667/N x (C/P)3

N = speed (rpm)

1. P = VFr

2. P = XVFr + YFa

P = dynamic equivalent load; V = rotation factor; X = radial factor; Y = thrust factor; Fr = radial load; Fa = axial load

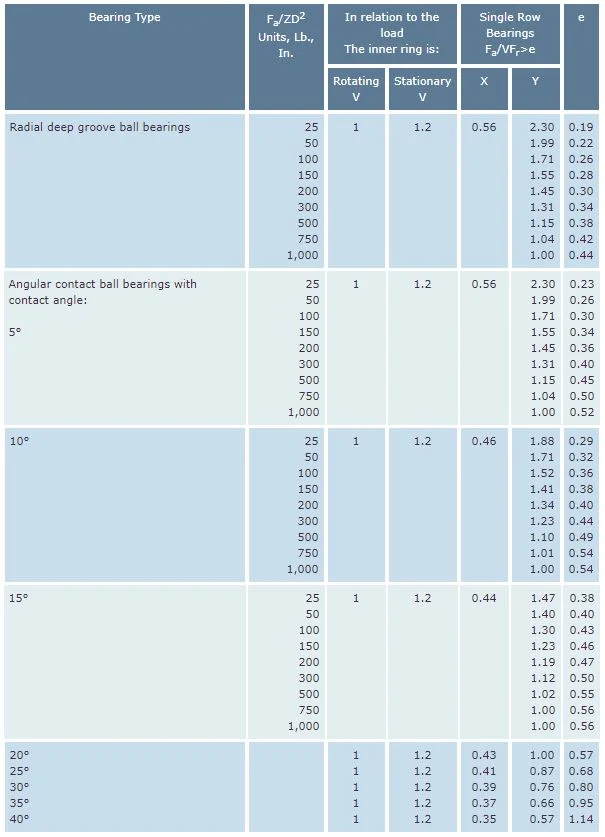

When the bearing outside diameter (OD) is equal to or less than 0.625 in, the following values can be used: X = 0.56, Y = 2.10 and e = 0.16. For bearings larger than 0.625 in in diameter, refer to the table below. Factor “e”, shown in the last column of the table below, represents the ratio of Fa/VFr. If Fa /VFr < e, then formula (1) is used; if Fa/VFr > e, then formula (2) is used.

While these formulas offer a good starting point, other factors can also influence effective bearing life and load ratings.

In some applications, the loads and speed may vary during operation. This can be factored into bearing load calculations if the load and speed variations are known variables.

Lubrication is another factor that can have a significant impact on bearing life. For sealed bearings, the life of the lubricant often determines the life of the bearing.

Environmental conditions and contamination can also adversely affect bearing life.

Bearing material may also influence performance. For example, load ratings for 440C stainless steel should be reduced by approximately 20% compared to 52100 bearing steel. Bearing life is not an exact science due to these factors and others, however, use of these formulas will help engineers develop a safe and reliable design for their assemblies.

Ball bearing design

The outstanding characteristics ball bearings are the result of technically demanding quality characteristics which achieve maximum performance limits. Various measures in design, such as preload or multiple arrangements of bearings, counter performance limitations and increase the performance capabilities of bearings.

PRELOADING BEARINGS

Preload is defined as a constantly acting axial force on a ball bearing which creates an elastic deformation in the contact area of the balls and raceways.

PERFORMANCE OPTIMIZATION THROUGH PRELOAD

Installing ball bearings with stiff or spring preload optimizes many performance characteristics for bearing operation.

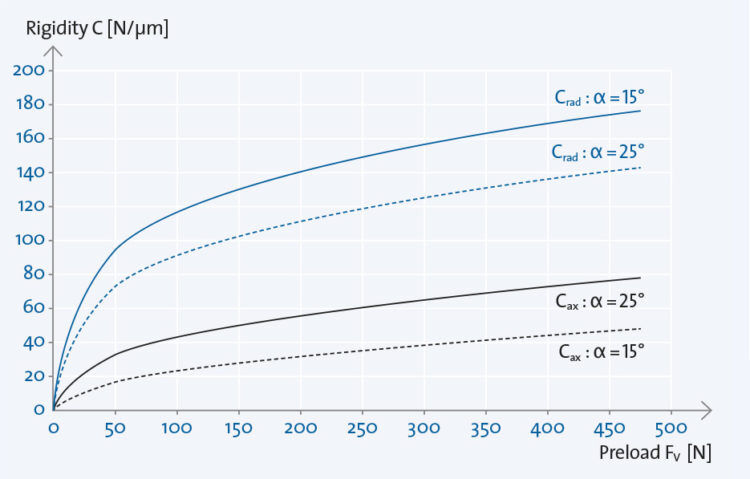

Reduced springing ensures the generation of a definable radial and axial rigidity (see diagram)

High running accuracy and workability even with changing loads

Reduced vibration and noise

Avoid slippage and friction in the rolling element contact at high speeds and high acceleration

Reduced sliding friction parts at high speeds (reduced contact angle change between inner and outer ring)

Increased load capacity (due to external loads and rotational speeds) with a long service life

RIGIDITY

Rigidity defines the amount of axial force effect [N] on the ball bearing, which causes a shift in the bearing ring by 1 μm.

Suitable preload increases bearing rigidity and supports the load carrying capability of the bearing against operating forces.

LIFTING FORCE

Lifting force is the force at which the bearing becomes load-free through a central axial load on a bearing set.

If the external axial load exceeds the lifting force, …

… the balls and the raceways of the unloaded ball bearing are no longer in constant contact.

… the wear is increased by increasing sliding friction.

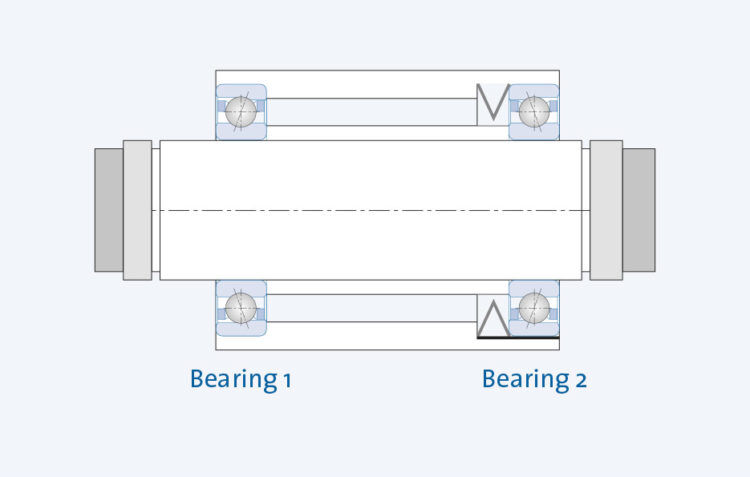

SPRING PRELOAD

DESIGN CHARACTERISTICS:

Bearing 1 (working side) is axially fixed in the housing, bearing 2 is arranged axially movably (fixed seat of the inner rings on the shaft)

The spring force on the outer ring of the bearing 2 ensures a constant preload for both bearings

The required spring preload is set by way of the spring travel (path-force function according to the spring characteristic curve)

For perfect preload results, a sufficient, axial mobility of the set outer ring on the floating bearing is required

The adjustment of the adjusting spring takes place in the direction of action of the external axial load

When using single bearings: <~>, untuned bearings can be used

When using bearings in tandem (<< ~ >>), bearings of the same type (L, M or S) ensure a uniform load distribution

CHARACTERISTICS: The preload – independent of speed and temperature – results exclusively from the spring force

The spring force results in an equal preload of the bearing and the thrust bearing

Thermal expansion of shaft and housing have no influence on preload

Spring-loaded bearing systems can have the highest speeds

RIGID PRELOAD BEARING SETS

The arrangement of several bearings in so-called bearing sets increases load bearing capacity, rigidity and lifting force.

Thus the radial rigidity for all arrangements is:

at α = 15°: Crad ~ 6 · Cax

at α = 25°: Crad ~ 2 · Cax

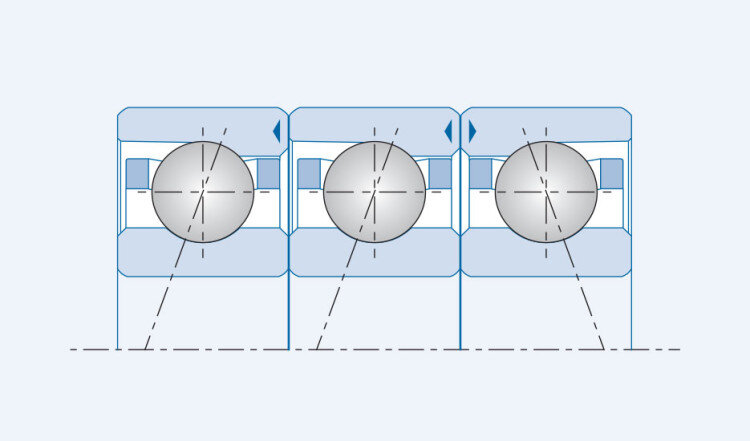

Example: Bearing set with 3 bearings in a TBT arrangement

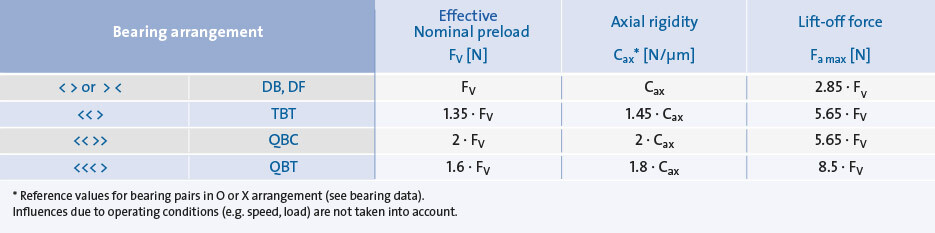

* Reference values for bearing pairs in O- or X-arrangement (see bearing data).

Operating-related influences (such as RPM, load) are not considered.

MULTIPLE ARRANGEMENT WITH 2 BEARINGS (BEARING PAIR)

With rigid bearing preload, specified bearing pairs in O, X or tandem arrangements offer an effective, cost-effective and technical solution for many applications.

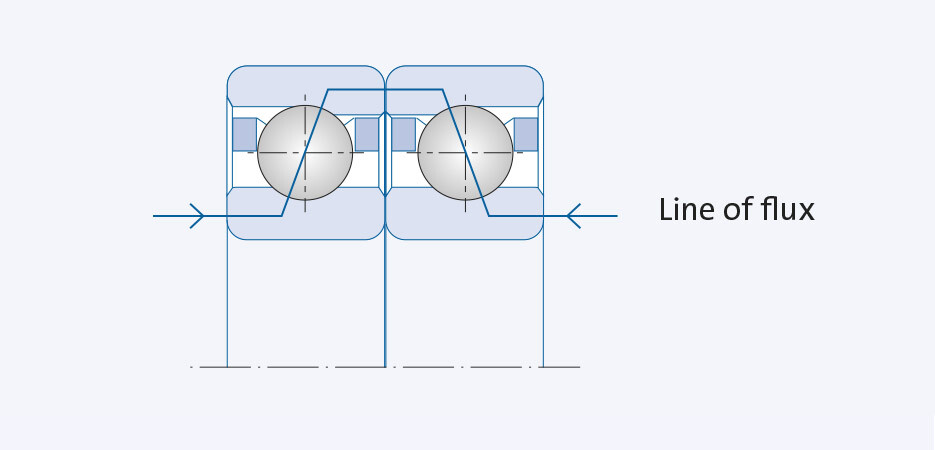

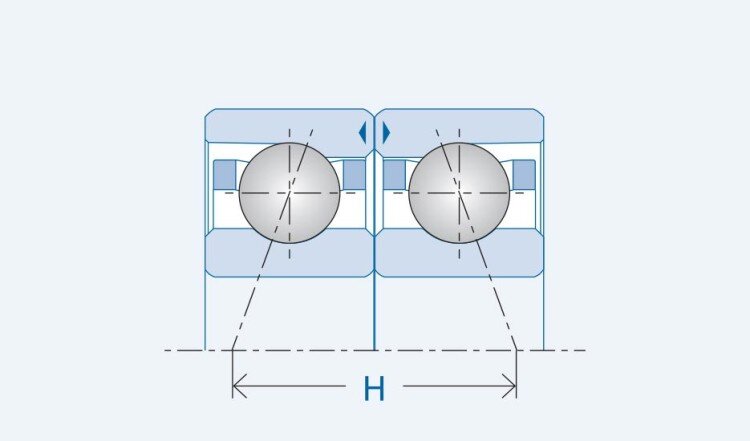

O ARRANGEMENT (DB)

>Pressure lines diverge in the direction of the bearing axis

>Large support base (H) and high rigidity against tilting moments

Axial force absorption in both directions

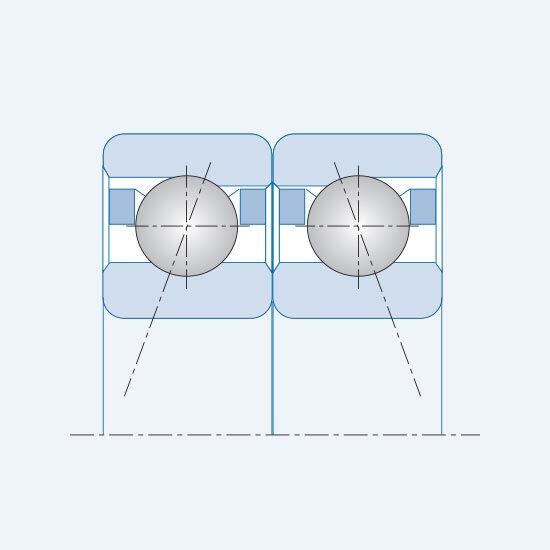

Bearing pair in O arrangement

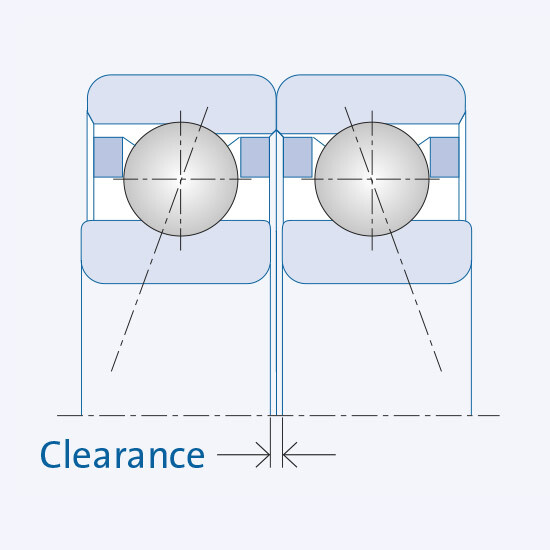

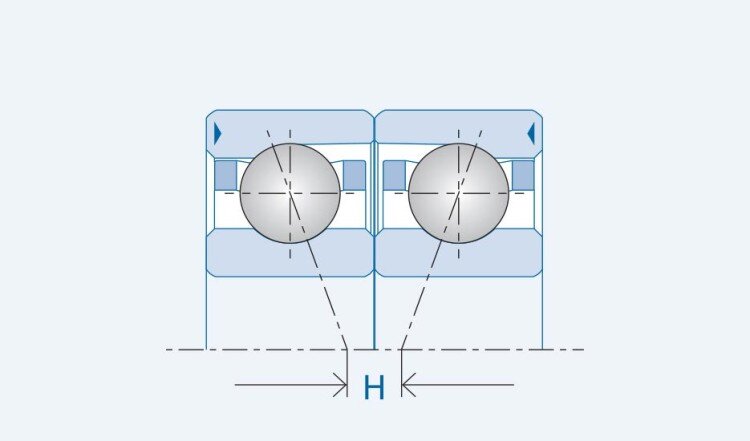

X ARRANGEMENT (DF)

Pressure lines converge in the direction of the bearing axis

>Insensitive to escape errors

>Reduced support base size and tilting rigidity

>Axial force absorption in both directions

Bearing pair in X arrangement

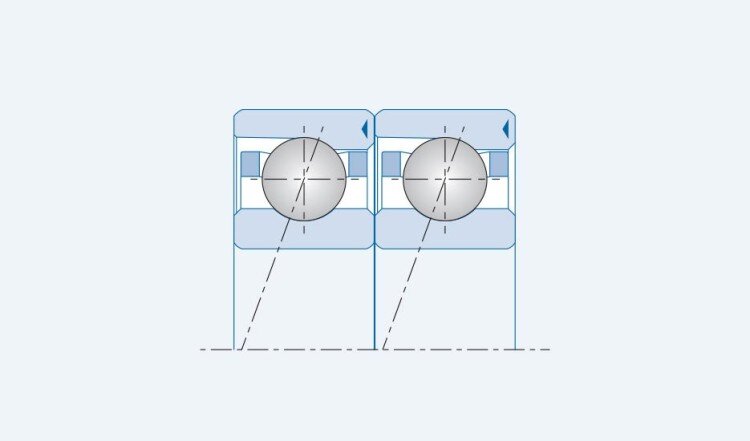

TANDEM ARRANGEMENT (DT)

Parallel arrangement to load direction

>Higher axial load capacity (factor 2) than single bearing

>Both bearings have the same contact angle and are placed against a third bearing

Bearing pairs in tandem

MULTIPLE ARRANGEMENT WITH 3 OR BEARINGS (BEARING SET)

With maximum requirements for system rigidity or high loads, X, O or tandem arrangements with 3 or bearings provide outstanding performance characteristics.

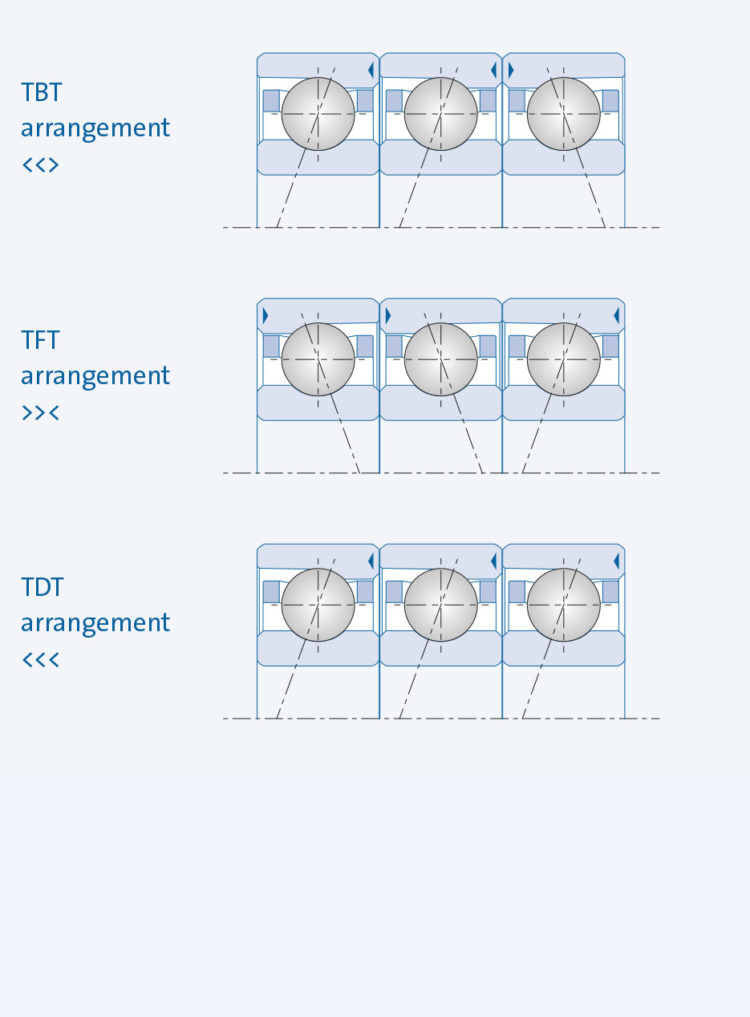

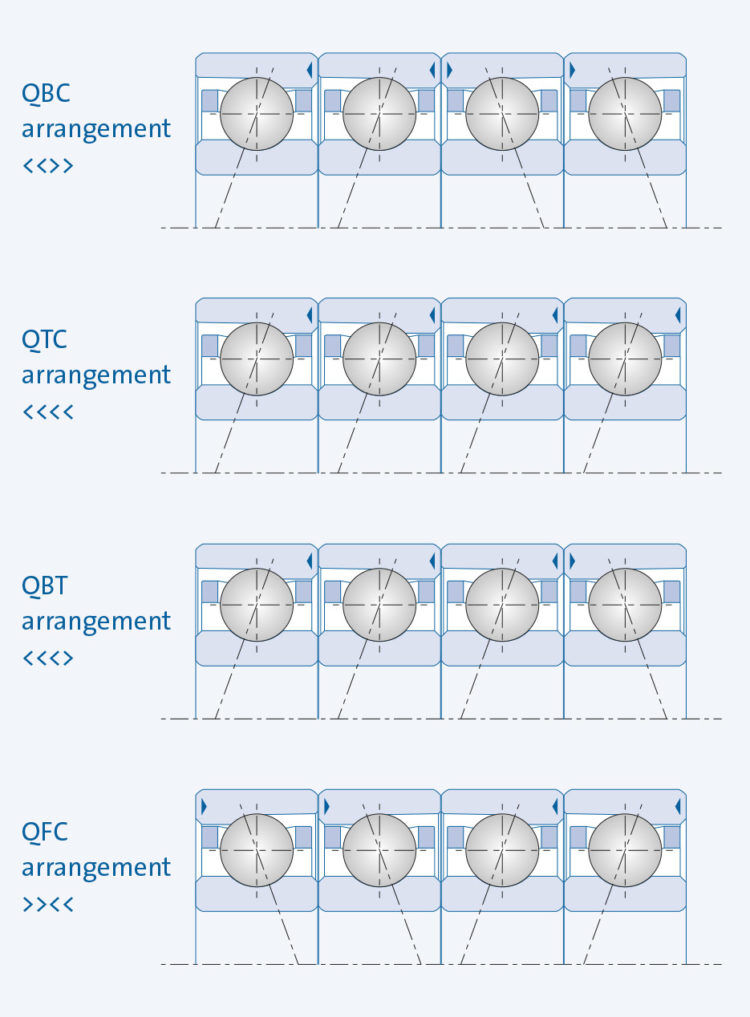

ARRANGEMENTS WITH 3 BEARINGS

ARRANGEMENT WITH 4 BEARINGS

INTERMEDIATE RINGS

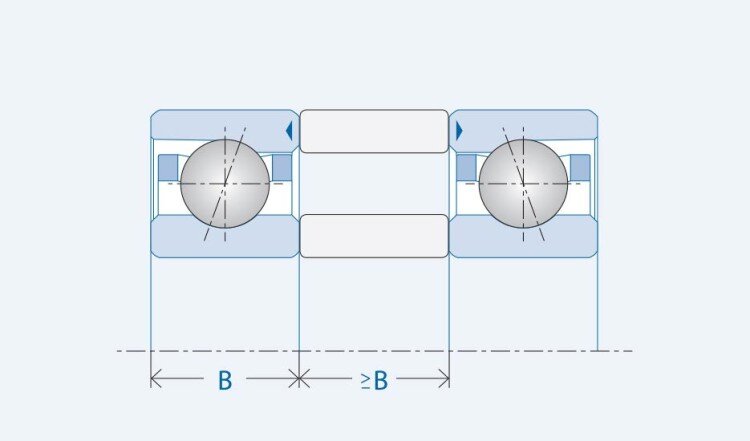

PERFORMANCE OPTIMIZATION THROUGH INTERMEDIATE RINGS

One can achieve differentiated optimization of individual quality characteristics of paired bearings by installing intermediate rings (distance rings). The width of an intermediate ring is at least the width of an individual bearing.

CHARACTERISTICS:

>Increasing the support base (H) and increasing the radial rigidity

>Optimization of heat dissipation

>Improved bearing lubrication thanks to optimized oil feed and discharge

Intermediate ring width ≥ Single bearing width

DESIGN CHARACTERISTICS:

>Material: 100 Cr6, or similar, hardened (at least 45 HRC)

>Care must be taken to ensure a good planar parallelism between the intermediate rings (see also the accuracy of the components).

>The required parallelism of the outer and inner intermediate ring is ensured by planar grinding of both rings in one clamping operation.

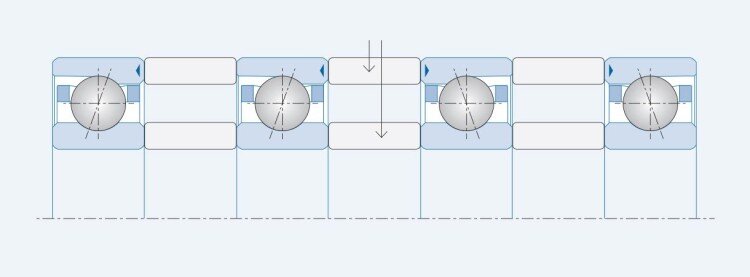

>In the case of bearing sets with intermediate rings (for example <||<||>||>), the spacer ring between the bearings is ground off with different pressure line trajectories and thus the pre-tensioning is coordinated.

Distance ring between different pressure line paths

CHANGE OF PRELOAD USING INTERMEDIATE RINGS

Intermediate rings provide a change to pre-tensioning for already coordinated ball bearings.

If the width of the shaft intermediate ring is less than the width of the housing…

… the preload in the O-arrangement increases

… the preload in the X array is reduced

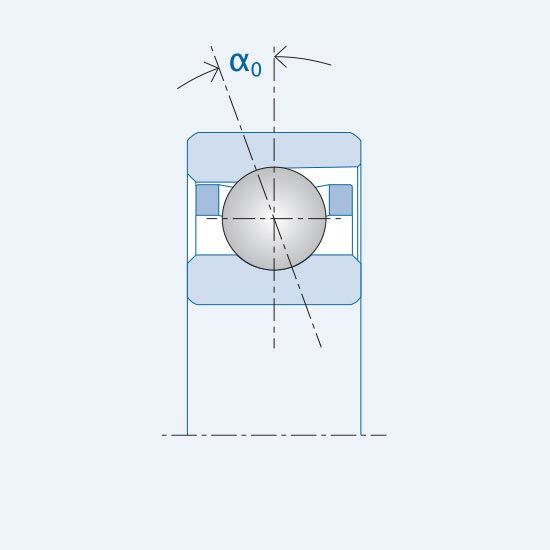

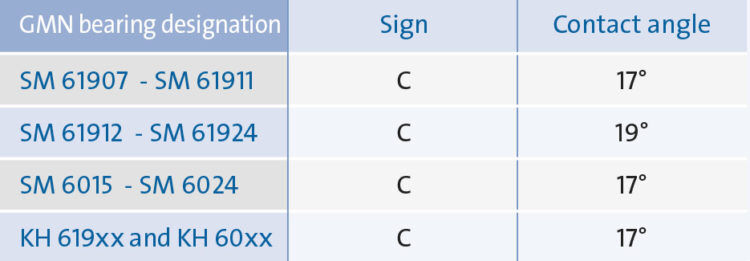

CONTACT ANGLE & COORDINATION PRECISION

CONTACT ANGLE ⍺0 The angle of the straight lines between the contact points: Inner ring raceway – ball – outer ring raceway and the radial level defines the contact angle.

The contact angle is determined depending upon the radial bearing clearance (bearing play) and osculation of the raceways.

Load transfers between both bearing rings are made over the contact points of the raceways with the balls.

Uniform load distribution on the individual bearings in bearing arrangements sets the same contact angle on all loaded bearings.

Standard contact angle C (15°) and E (25°) )

THE CONTACT ANGLE IS CHANGED DEPENDING UPON OPERATION THROUGH …

… external forces

… internal forces

(Centrifugal force of inner ring and balls at high speeds)

… inner ring fits

… temperature differences from inner ring to outer ring.

Deviations of the contact angle cause changes to the bearing characteristics,

which influence bearing operation.

Further contact angles are available on request.

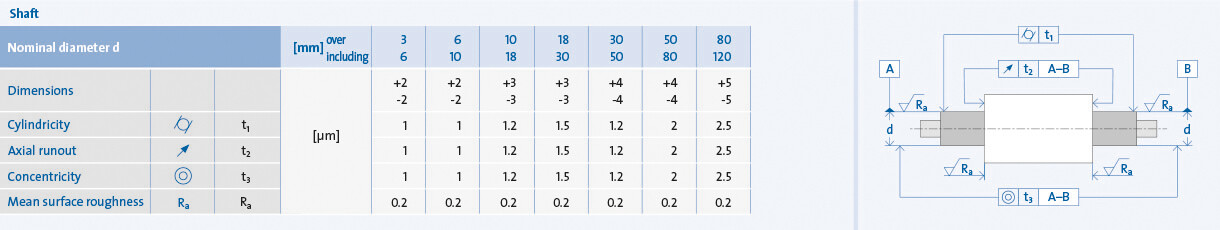

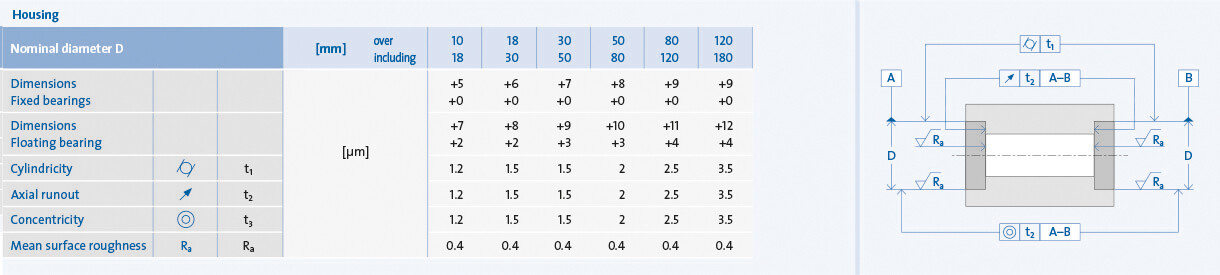

PRECISION OF THE CONVERSION PARTS

Guidance values for shaft adjustments and shape and position tolerances (DIN EN ISO 1101)

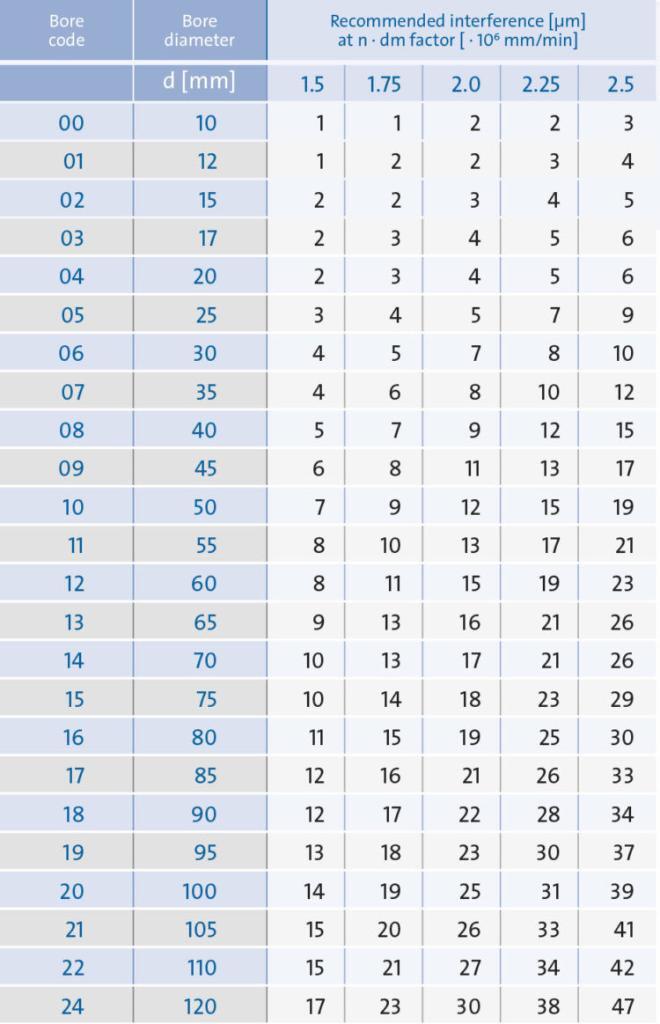

OPTIMIZATION OF THE FIT WITH HIGH RPMS

With increasing RPM (from about n · Dm = 1.5 . 106 mm / min.), the progressively increasing centrifugal force can cause a widening of the internal ring, and lead to functional impacts. For example:

>Slipping of the inner ring at the contact with the shaft and at the contact surfaces

>Frictional corrosion

>Vibrations

In order to counteract the lifting of the inner ring, a stronger fit is recommended.

Correction factors for an oversized bearing design and bearing series:

SM 60..: 1

SM 619..: 1.10

KH 60..: 1.05

KH 619..: 1.15

Valid for solid shafts. For hollow shafts (50%): Correction factor = 0.8

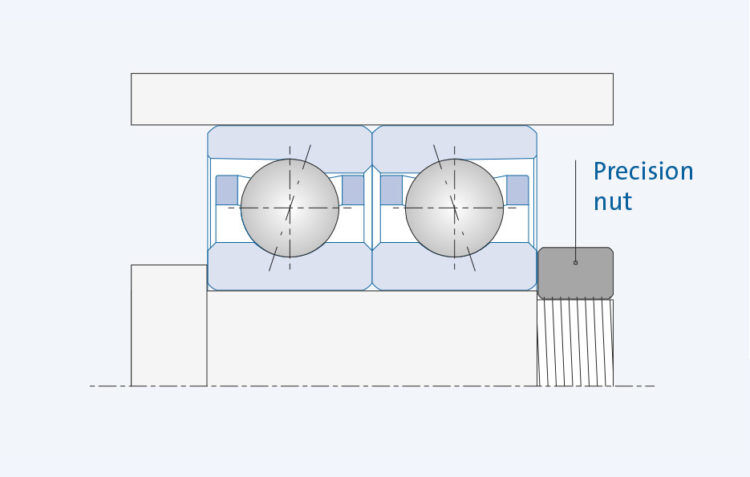

TENSIONING BEARING SETS TOGETHER

PERFORMANCE OPTIMIZATION THROUGH PRECISION NUTS

The use of precision nuts to clamp bearings (sets) supports an optimal utilization of the performance capacity of GMN high-precision ball bearings.

DESIGN:

Careful installation with precision nuts prevents (interruption out, possibly follow up with a hyphen: micro-movements);

micro-movements cause contact corrosion.

>Grind the sides of the nut at a right angle to the thread of the nut and the shaft to prevent tilting of the bearing or bending of the shaft (max 2 μm run-out tolerance)

>Fix the precision nut on the shaft (against loosening)

>Intermediate washers and bushes must be made parallel to the planes (max. 2 μm)

A sufficiently high axial clamping force fixes the bearings in the intended position and ensures the required preload, precision and rigidity of the bearing.

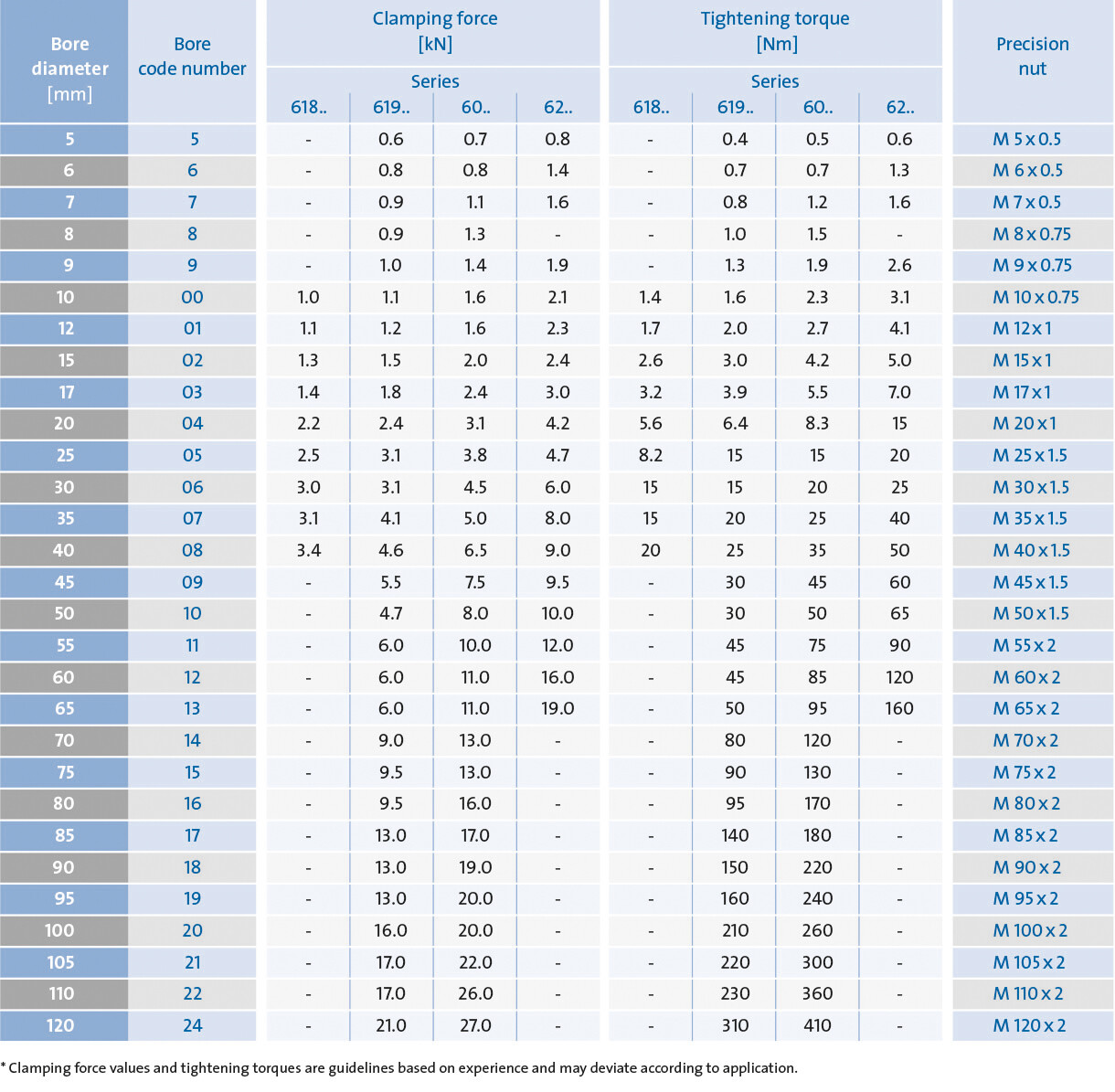

INSTALLATION:

>Lightly lubricate the thread

>Screw in the precision nuts with 2 to 3 times the TARGET tightening torque, then release them again and fasten them with the desired torque (compensation of temperature-dependent dimensional changes of the inner rings and seatings)

>The required press banding of several bearings (axial) and the necessary overcoming of friction resistance when the bearings are pressed on the shaft (radial) are ensured by the 2 to 3 times primary (breakout) tightening torque

Values for clamping forces and tightening torques are experience-based indicative values and may differ depending on the application.