Custom Bearing Manufacturing

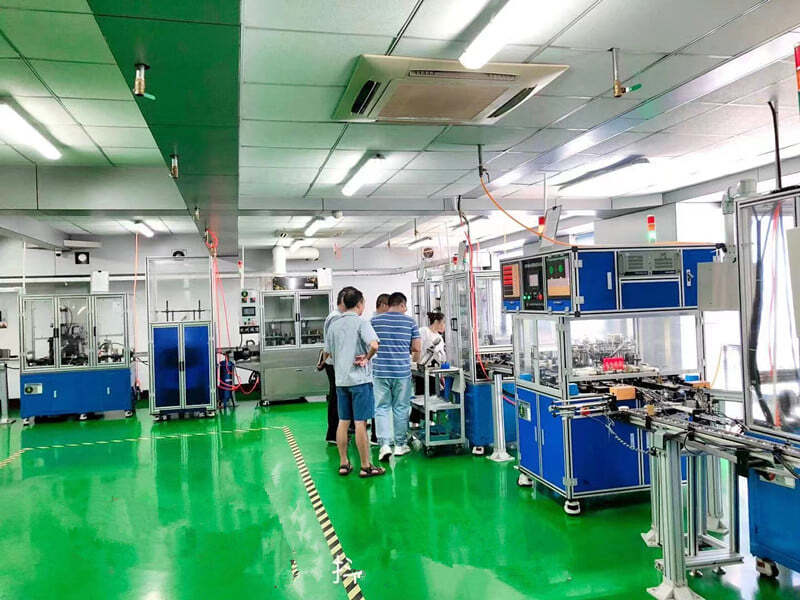

Aubearing has over 20 years of experience in custom bearing manufacturing solutions and a solid understanding of industry specific requirements. To name a few, we serve customers in the automotive industry, agriculture, forestry, medical, mining, railways, wind power and – for every application, from the smallest equipment to the largest machines. In our 8000 square meter factory, automated manufacturing lines and years of knowledge reserves of 160 engineers, we can provide you with all the bearings you need.

At Aubearing, we are known for our bearings manufactured using 52100/ GCr15 bearing grade steel, a chromium containing high carbon alloy material that offers excellent strength, wear and fatigue properties. Custom chrome steel bearings have a higher dynamic load capacity than 440C stainless steel bearings and are significantly less expensive than bearings made from tool steel materials. We also produce several other steels, stainless steels, ceramics and plastics for corrosive environment applications such as the pool and spa industry, medical devices, health and beauty appliances (HBA), and the semiconductor industry. In addition, we also offer bearings made of selected engineering plastics.

Custom Bearing Manufacturing Solutions

Aubearing design your special bearings to solve operating environment issues, extend service time, improve equipment performance, and even save energy. The housing it needs to fit in, the tasks it needs to perform, the weight it needs, Aubearing custom bearing experts will design a solution to achieve all of these goals quickly and at a competitive cost.

Custom Bearing Manufacturing Services

① If customer have the drawing, which includes the dimensions, materials, special requirements, then we can make the mold according to the drawing.

② If customer have no drawing, we can design according to customer request, to make a drawing and get confirmation from customer. Then we make a mold according to the drawing.

We will prepare Mould to make shipments, and send samples for customer approval before shipments

After test the mold, if the mold is ok. Then make the samples, our engineer will measure the After samples confirmed, we will make documents and book vessel to ship to customer , sometime if urgent by air.

The production flow as bellow:

Raw Material booking → Raw material testing → turning process → heat treatment → grinding process → products inspection → super grinding process → bearing rings cleaning process → Bearing assembly → Bearing cleaning → bearing greasing/sealing process → quality inspection → logo marked–package .

Then we will ship our goods, small quantity, usually by express transport , such as FedEx , DHL, TNT, UPS, or by air. If large quantity, usually by ship or land transport ,or by air .

Professional bearing manufacturer with 20 years experience

At the heart of Aubearing is our ability to work with our customers on unique designs and applications. Since we only supply precision bearings and related products, we are veritable precision bearing experts. Our team of design engineers and experts has 20 years of combined expertise.

It is a pleasure to visit our factory, we invite you to visit our advanced CNC machine tools and testing equipment. Together we can create cost-effective solutions to your most demanding specifications, often with tolerances measured in millionths of an inch.

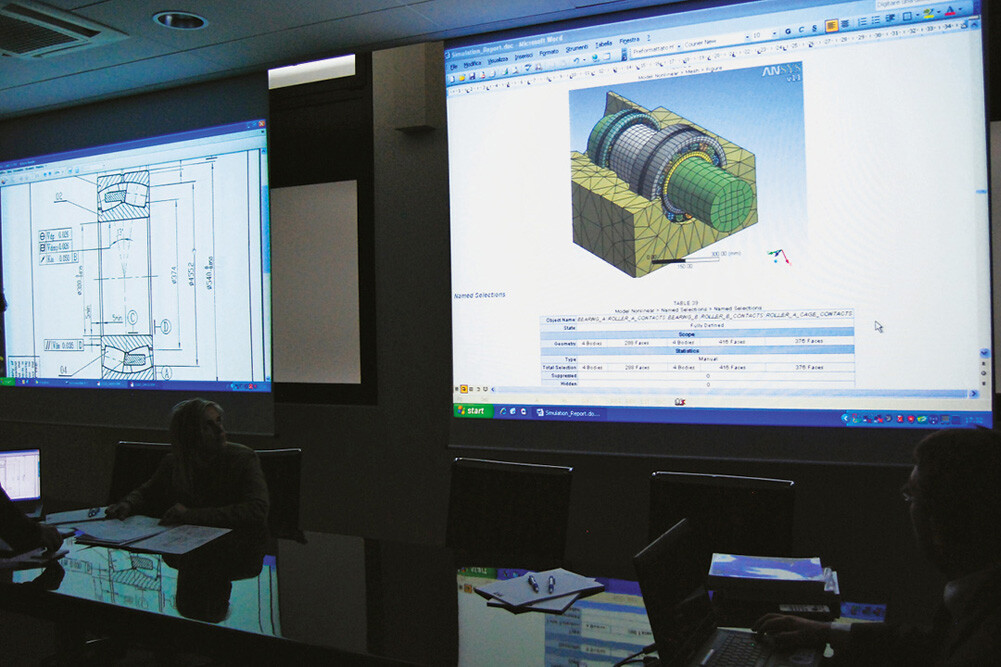

Our technical laboratories are equipped with state-of-the-art precision instruments and computerized equipment to quickly and efficiently evaluate bearing applications. The unique “Aubearing Analysis System” evaluates bearings from multiple perspectives, including load and speed requirements as well as environmental factors that may affect performance.

Manufactured custom, standard bearing types:

Thin section bearings

Miniature Bearings

Roller bearings

Thrust bearings

Slewing bearing

Spherical bearings

Roller Thrust Bearings

Angular contact ball bearings

Outer spherical bearing

Composite spherical bearing

Needle bearings

Linear ball bearings

Linear lubrication-free bearings

Linear replacement bearings

Oil-free bearings

Straight sleeve bearing

Thermoplastic bearings

Custom Bearings Dimension

Custom bearings are available in a range of bore and outside diameters and lengths in inches or metric. Standard bearings are also available:

Inner Diameter: 3 – 300mm

Outer Diameter: 4.5 – 6000mm

Length: 2.5 – 210mm

The dimensional tolerances of bearings vary by type, material and ABEC quality class:

Outer race tolerances for mounting dimensions from -.0005 to +.0050”

Inner race tolerances for installed dimensions from -.0005 to -.0050”

Bearings run with outer ring tolerances from .0001 to .0010”

Bearings run with inner race tolerances from .0001 to .0006”

Material options for custom bearings

Aubearing manufactures metal and plastic bearings from a variety of materials including:

17-4 stainless steel

400 Series Martensitic Stainless Steel

410 stainless steel

410 remote control 23-25

440C stainless steel

316 stainless steel

52100 Chrome Steel

52100 Hardened Chrome Steel

Low-carbon steel

1008 carbon steel

C1075 carbon steel

6061-T6 aluminum

356-T6 cast aluminum

brass

Sintered bronze

Sintered bronze MIL-B-5687 Type 1 oil impregnated

Steel backed porous bronze and PTFE lead

thermoplastic

Reinforced Thermoplastics

Fiberglass and Epoxy Matrix

Molybdenum disulfide filled nylon

Fluorine lining

Teflon™ lining

Teflon-MiL-P-19468

Typical types of custom bearings and their applications

Aubearing manufactures many different types of custom bearings. Our engineers can customize standard bearings or design fully custom engineered bearings to meet your application needs.

Custom Ball Bearings

Custom ball bearings manufactured by Aubearing, custom options include single or double row, flanged or non-flanged, open or shielded. Our stainless steel and plastic ball bearings are ideal for high precision applications requiring tight tolerances and high running accuracy.

Common applications that require custom precision ball bearings:

Rotary joint

Industrial robot

Medical and Laboratory Equipment

Motion Control System

Aubearing also offers standard ball bearings.

Custom Angular Contact Bearings

Aubearing manufactures custom angular ball bearings, options include ball and cage, sealed sealed or open, preloaded bearings are ideal for high speed operations where stiffness and bearing load support is required.Common applications where contact bearings need to be identified:

Centrifuge

Dynamometer

Vacuum pump

Machine tool spindle

Motors and Generators

Customized oil-free bearings

Aubearing produces oil-free lubricated bearings Bearings with high load capacity and high impact/temperature resistance are very suitable for moderately heavy loads and low speed applications, and are also suitable for operating environments that require moisture or corrosion resistance. Common applications that require custom oil-free bearings:

Dryers and kilns

Industrial shutters

Injection molding equipment

High temperature conveyor

Aircraft cockpit, door and compartment mechanisms

Custom spherical bearings

Aubearing manufactures custom spherical bearings, options include self-lubricating center spherical toroidal bearings toroidal bearings, and self-aligning spherical toroidal custom made to order custom options include bore, single or double, or non-sealed, seal-retained. Spherical bearings are ideal for rubbing and heavy duty applications where shock/vibration resistance is required. Common applications requiring custom spherical bearings:

Robotics

conveyor beltPackag

ing Equipment

Textile Manufacturing

Heavy Industry Machinery

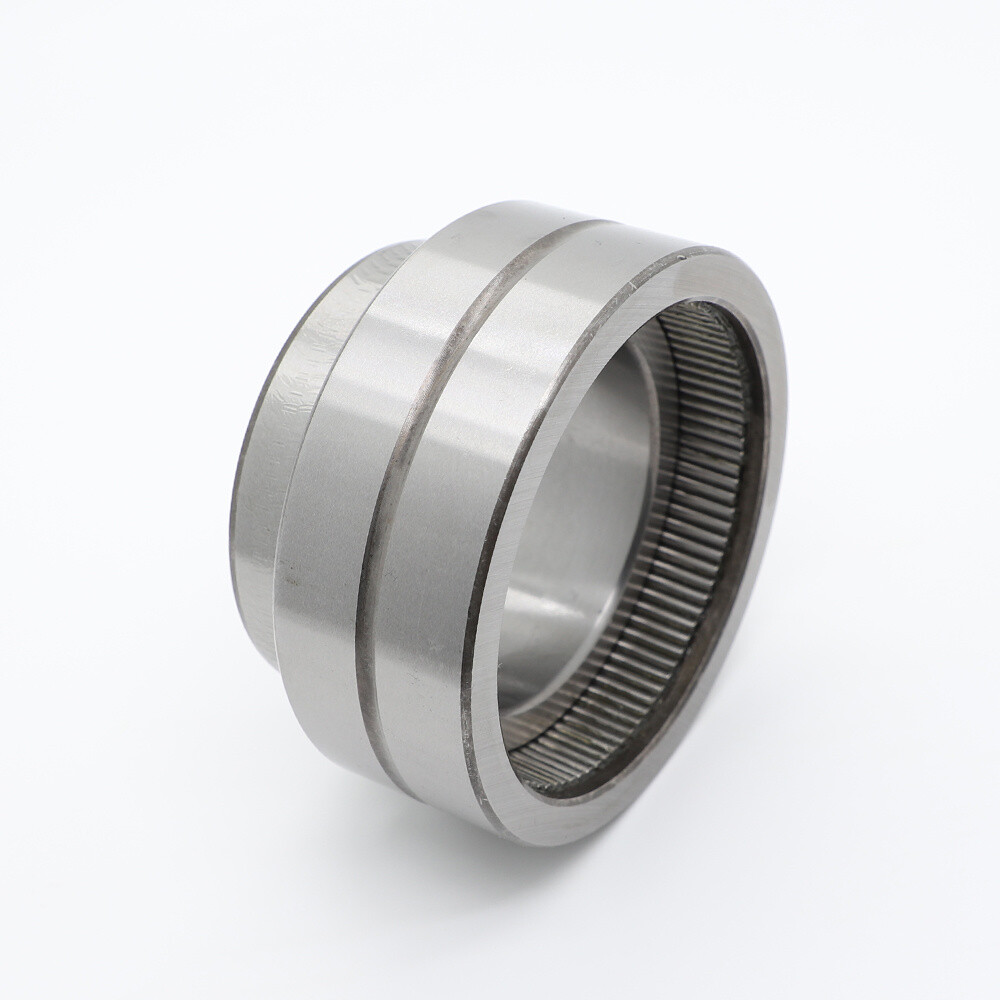

Custom Needle Roller Bearings

Aubearing manufactures custom needle roller bearings. Custom options include single or double row of rollers, open end or one closed end, with or without cage, with or without lip seal. Drawn cup needle roller bearings are ideal for applications requiring compact, economical bearing arrangements, including gearbox shaft supports, pulley supports and chain drive sprockets.

Common applications that require custom needle roller bearings:

Machine Tools/Power Tools

Printing Equipment

copiers and fax machines

Lawn and Garden Equipment

Radial Piston Pumps for Industrial Equipment

Custom Plain Bearings

Plain bearings manufactured by Aubearing are made of fiberglass and epoxy resin matrix with Teflon™ lining and Duralon® coating. Custom options include material, bushing clearance, ID/OD and length. Journal bearings absorb or modify friction between moving mechanical parts, reducing noise and vibration. Sleeve bearings are extremely versatile and can be used in countless applications involving linear, rotary or oscillating motion.Common applications requiring custom journal bearings:

Heavy industrial machinery such as pumps, turbines, blowers, compressors and fans

Industrial Motors and Gearboxes

Interior aircraft systems such as cockpit controls, doors, seats and storage bins

Medical technology such as prosthetic joints, dialysis machines and adjustable beds

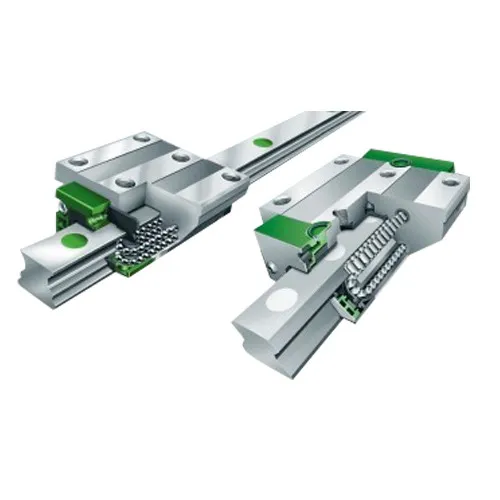

Custom Linear Bearings

Aubearing manufactures linear ball bearing slides in open or adjustable diameter styles. Custom options include ID and OD and length. Linear ball bearings are ideal for applications requiring smooth, precise linear motion on a single axis.Common applications that require custom linear bearings:

material handling

robot machinery

cutting machine

automated manufacturing

automation window

sliding drawer

Sun Tracking Solar Panels

Custom Plain Linear Bearings

Aubearing manufactures single axis linear motion bearings bearings bearings bearings bearings bearings bearings bearings linear linear linear components. Custom made options for our linear no-wet no-wet include closed-back, open-back, or adjustable-style, available in Duralon® models, and can be made to size.

Common applications that require custom linear plain bearings:

medical scanning equipment

Cutting Machine

Industrial Robotics and Automation

sliding door

3D printer

Custom Roller Thrust Bearings

Thrust bearings support axial loads (forces in the same direction as the shaft), reduce friction and allow mechanical parts to rotate. Standard and custom thrust bearings are available in C1075 carbon steel or 410 stainless steel, sized to your specifications. Thrust ball bearings are suitable for applications involving high speeds and light loads, while roller thrust bearings are suitable for heavy load applications.

Common applications requiring custom thrust bearings:

Industrial machinery with rotating shafts such as generators, compressors, blowers, pumps and turbines

Medical technology with rotating axes, such as dialysis machines, blood or infusion pumps, endoscopes, centrifuges, cutting tools, etc.

Fans for aircraft air supply systems

fluid control valve

mechanical tool

Custom Roller Bearings

Roller bearings use cylinders instead of balls as the rollers. Roller bearings can carry heavier loads than ball bearings and can include multiple rows of rolling cylinders to increase load capacity. Aubearing manufactures two types of roller bearings: needle roller bearings and thrust roller bearings.

Common applications requiring custom roller bearings:

Air Cargo Handling System

Industrial Conveyor System

medical imaging equipment

Precision Motion Control Systems for Robotics or Machining

Custom Thermoplastic Bearings

Aubearing manufactures sleeve or flanged thermoplastic bearings. Thermoplastic bearings are corrosion resistant, making them ideal for cleanrooms, food service applications, and harsh or corrosive operating environments.

Common applications requiring custom roller bearings:

Pharmaceutical and chemical

manufacturing

Packaging Equipment

motorized camera rocker

snowboard binding

Prosthetic joint

adjustable seat

The Benefits of Customizing with the Original Manufacturer

Guaranteed fit and function

faster production time

Quality Assurance

Reduce long-term replacement costs

1 year warranty

Precision bearing manufacturing process

For over 20 years, Aubearing has been a leader in the engineering and production of quality precision components. Working with a custom precision bearing manufacturer has never been easier. Our product experts are with you every step of the way, from design and manufacturing to shipping and installation support. Our production process uses AQL sampling and lean manufacturing tools to provide consistent quality, repeatability and economy.