Bearing Repair Service

Aubearing is an industry leader in providing reliable, efficient bearing repair services for all types of bearings, including older models that are no longer in production. It can be very frustrating when you encounter this type of unavailable bearing issue, especially if the issue affects your business’s productivity. Calling suppliers to find these parts can be a long and tedious process, and in the end, there’s no guarantee you’ll find what you need in the first place. The experts at Aubearing can help keep these older machines running by providing an efficient bearing repair service that will keep your operation running smoothly without the added expense associated with rare bearings. Bearing repairs are fast and effective.

Aubearing remanufactured bearings perform as well as brand new and can significantly reduce the initial cost – up to 75% compared to the cost of new bearings. Aubearing remanufacturing services can extend bearing lifecycle by 50% or , reduce total lifecycle cost, and reduce unplanned downtime. Remanufacturing is particularly beneficial for bearings exposed to harsh conditions, such as those used in mining, pulp and paper, metals and construction. We repair bearings as small as 10″ (25 cm) and as large as 315″ (8 m).

Bearings suitable for repair

Large number of bearings of the same size

Obsolete bearings

Large bearings over 12″ bore

Expensive bearings over $2000

Repaired Bearing Types:

Tapered roller bearings

Spherical roller bearings

Cylindrical roller bearings

Ball bearings

Standard and custom designs of all types

Radial, Thrust and Bearings

Proven Bearing Repair Process

The bearings you need repaired are shipped to our repair center to begin the repair process. From there, our team will take the time to inspect the bearings so we can determine the extent of the damage and the type of repair the parts need to get them working properly again. Once we have a strategy in place, we will discuss these issues with you, providing you with a breakdown of the repairs that need to be made, as well as lead time and cost estimates. From there, we can perform the job and ship them back to your business as quickly as possible to minimize downtime for your business. Saves you the hassle of finding discontinued parts from suppliers who charge a premium for those parts.

| Bearing Repair & Reconditioning Services | Class I | Class II | Class III |

| Clean, disassemble and inspect all components at no charge. | ✓ | ✓ | ✓ |

| Provide a report including visual observations and dimensional data and an estimate for repair. | ✓ | ✓ | ✓ |

| Polish all components. | ✓ | ||

| Polish non-ground surfaces, regrind raceways and manufacture new rollers. | ✓ | ✓ | |

| Clean, modify or replace cages. | ✓ | ✓ | |

| Inspect for quality during remanufacturing. | ✓ | ✓ | |

| Manufacture replacement components and new rolling elements, reset clearances, reassemble, and repackaging. | ✓ | ||

| Conduct final quality inspection. | ✓ | ✓ | ✓ |

| Mark bearing with repair information, repackage and label as repair. | ✓ | ✓ | ✓ |

| Return ship at no charge. | ✓ | ✓ | ✓ |

Remanufacturing process

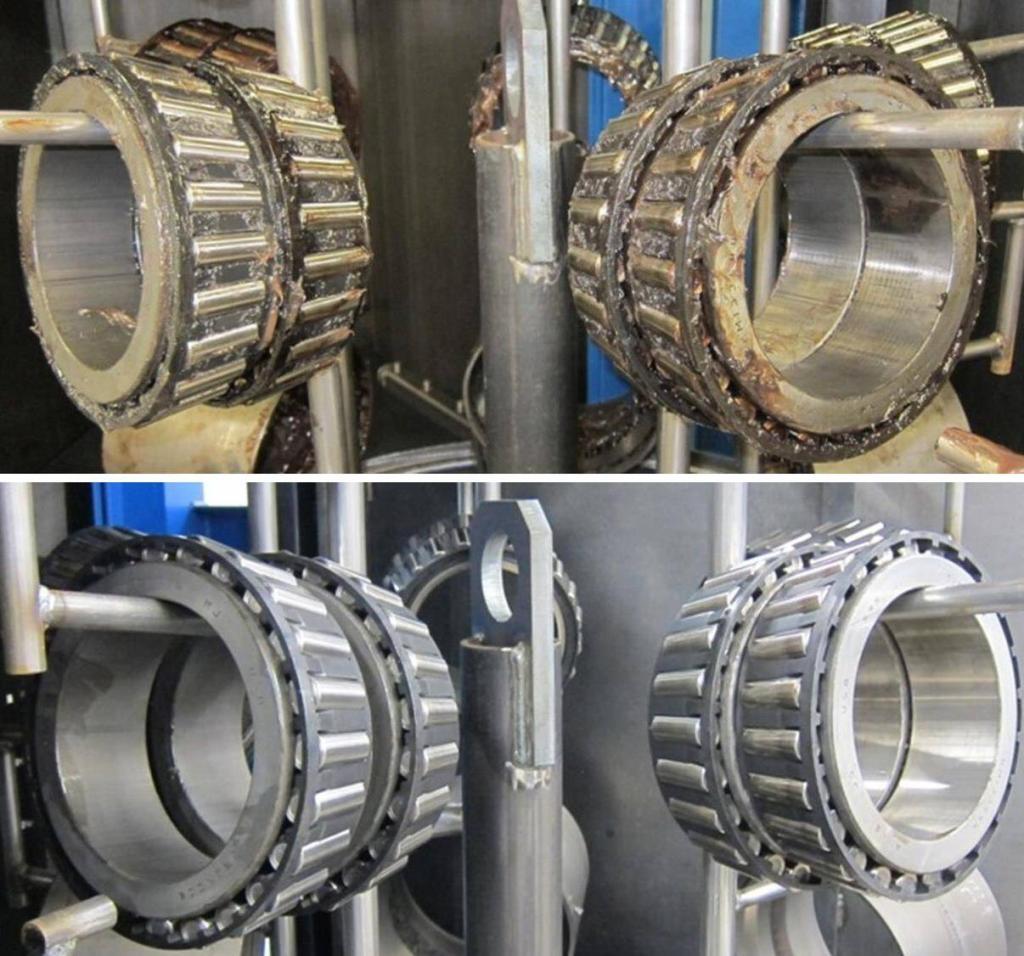

Once a bearing is damaged, it should undergo a rigorous process to determine if it is a candidate for repair.

Bearings to be repaired should be thoroughly cleaned. Next, and the most critical step, is a detailed inspection on 100% of the bearing. Inspection begins with a careful review for major damages such as fractures, significant spalling, and bluing due to excessive heat. Any evidence of these usually results in scrapping the bearing.

If the bearing passes the first stage of inspection, it should undergo further review. This step serves to reveal a mode of damage, assessment of damage, and the scope of repair. The degree of bearing repair typically fits into three types.

Type I reconditioning is used for minor trouble spots and includes polishing, resetting of internal clearances, and spot grinding of any small surface defects to prevent further damage.

Type II repair is for bearings with extensive damage. This level involves major procedures such as regrinding of races, new spacers, and polishing of the bore and cup OD. The regrinding of raceways will also necessitate the manufacture of oversize rollers to maintain bearing geometry and clearance.

Type II repair is for bearings with extensive damage. This level involves major procedures such as regrinding of races, new spacers, and polishing of the bore and cup OD. The regrinding of raceways will also necessitate the manufacture of oversize rollers to maintain bearing geometry and clearance.

These levels of repair have traditionally been suited for bearings with a minimum bore size of 8 in. However, reclamation service can be done for bearings as small as 3-in. OD.

Smaller bearings that were often thrown away can now be repaired if there are large quantities. Cleaning, inspection, and the application of a polished finish can return used bearing to good-as-new condition for a fraction of the cost of replacement.

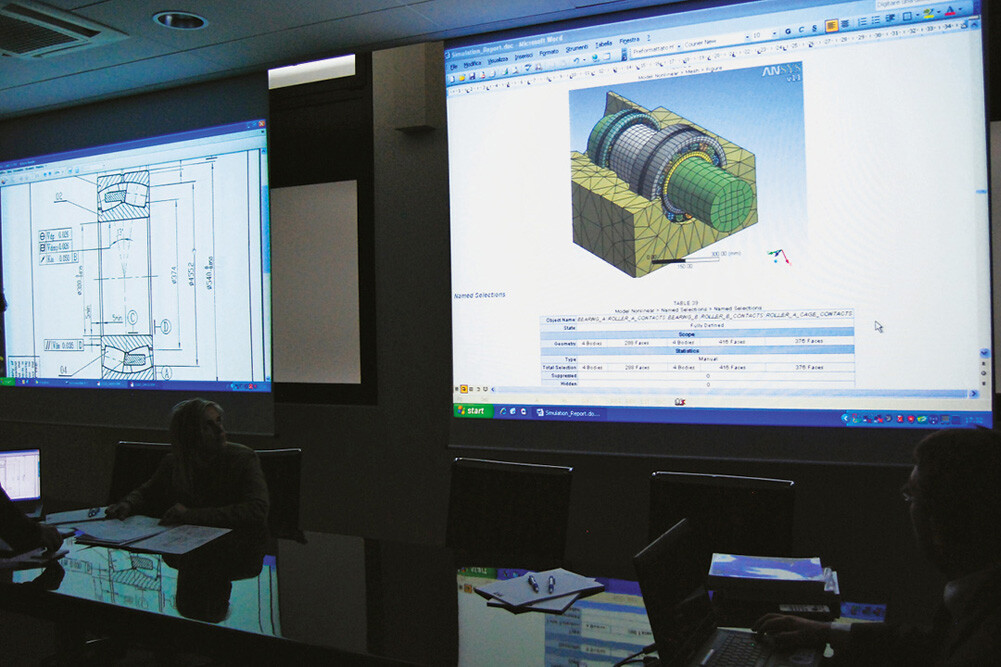

Advanced equipment, experienced engineers

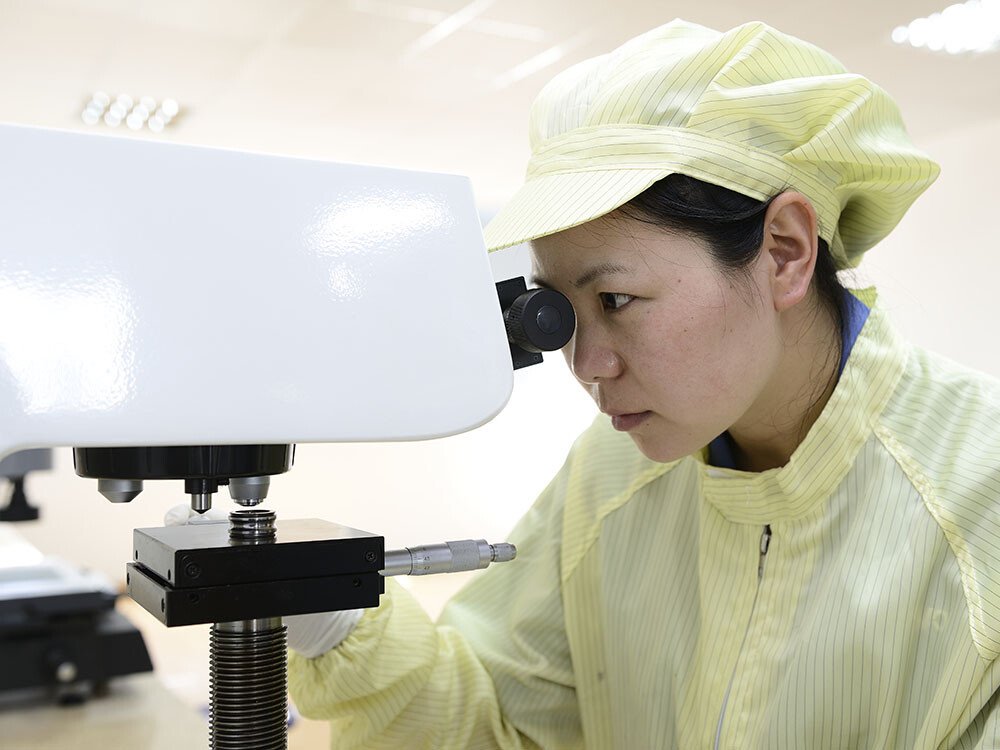

Our approach to bearing remanufacturing mirrors our manufacturing capabilities. Aubearing’s experienced remanufacturing staff is supported by professional engineers and professional advanced equipment. Our bearing remanufacturing process is designed to return bearings to service in the shortest possible time and to ensure the highest quality workmanship. In-house multiple Computer Numerical Control (CNC) and Electrical Discharge Machining (EDM) machines, CNC mills and CNC lathes, as well as experienced craftsmen, means that all work on bearings or seals can be carried out on site, saving customers time and money. Our state-of-the-art equipment, professional measuring machines and reliable quality inspections ensure that jobs are completed with precision and speed.

When to Service Bearings

Despite its many benefits, restoration is not always the best option for damaged bearings. The challenge in properly utilizing bearing repair services is determining if and when a bearing needs repair and determining which options are the most economical and long-term decision.

Visual inspection is the first step in determining whether a bearing needs repair. Careful review of other criteria can help determine if repairs are needed, such as:

Are the bearings approaching or past their recommended life expectancy?

Is the operating temperature above 200 F?

Are the bearings exposed to excessive vibration?

Are the bearings subject to lubrication or sudden changes in temperature?

Early detection of problems through routine inspections can save companies unnecessary downtime and expense, and help leverage the capabilities and advantages of bearing repair.

Regardless of manufacturer, bearing type or application, proper handling can protect and restore a bearing to like new condition for continued use. Bearings with little or no damage can usually be repaired and recycled easily and at low cost.

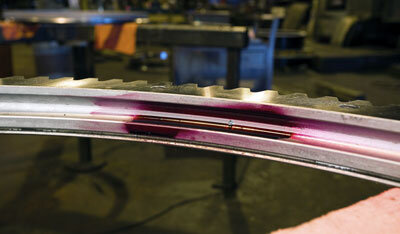

Importance of lubrication to bearings

Lubrication is not just an additive to machines. Rather, it is an integral part of the machine and as such should be closely monitored to ensure it maintains its quality. Essential to all moving parts, especially bearings, lubrication is used to remove heat and protect bearing surfaces from corrosion and wear.

Too little lubrication can cause extra friction and heat, which can lead to premature failure of the bearing. Excessive lubrication at high speeds creates additional heat due to agitation, which can lead to thermal breakdown of the lubricant and eventually bearing damage.

Bearing problems caused by insufficient lubrication can take many forms, including roller end scoring from metal-to-metal contact and excessive roller and raceway wear. Excessive heat generation can result in scoring or “welding” damage or deformation of the cone’s large rib face. In extreme cases, insufficient lubrication can cause the rollers to skew or slide sideways, causing the bearing to lock up.

There are signs of under- or over-lubrication of the bearings. If these signs are detected quickly enough, the situation can be corrected before catastrophic damage occurs. If there is insufficient lubrication, the gauges and operating temperature will show that the bearing is running hot and there will be noise from metal to metal contact. In the case of over-lubrication, the lubricant will decompose due to the increase in operating temperature, for example, the color will change to dark brown or black.

Bearing damage due to lubrication problems can be avoided with proper lubricant application and a regular maintenance schedule. Here are some tips for ensuring proper bearing lubrication:

Follow the lubrication guidelines established by the equipment manufacturer

When greasing a bearing, press the grease firmly between the rollers and cage to ensure that the bearing is completely filled

Watch for early signs of problems with equipment gauges, such as unusually high temperatures

Listen for noise or unusual vibration

Watch out for lubricant leaks.

Bearing repair case

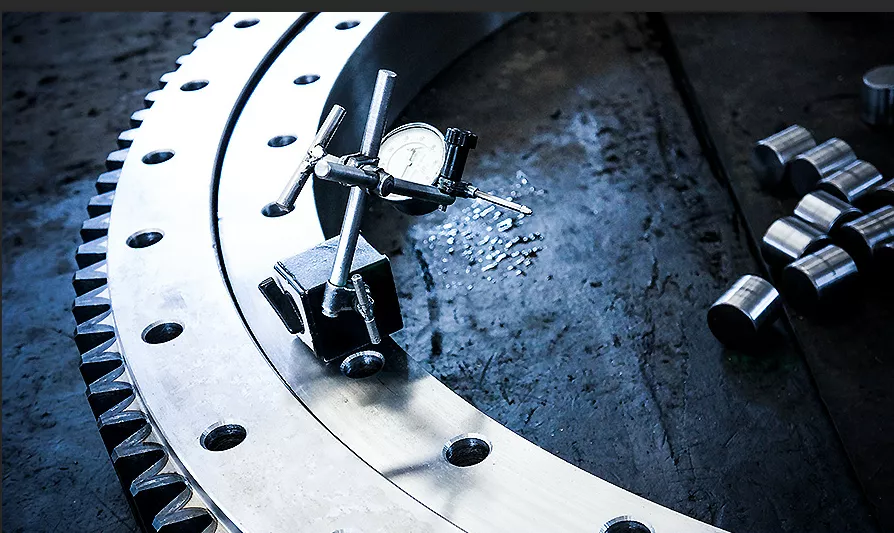

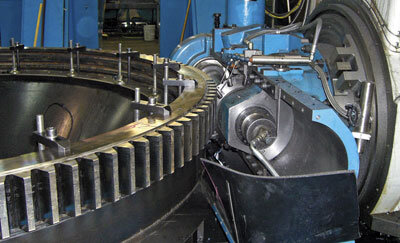

In 2022, a slewing ring bearing produced in 1998 used by a mining company stopped working. The original supplier has discontinued bearings for that model. The mining company searched for “bearing repair” on Google, retrieved the Aubearing website, and contacted us actively to request repair of this slewing ring bearing. Aubearing accepted the order and completed the repair after 3 weeks. Customers are very satisfied. The repair process is as follows:

initial check

Inspection and recording of rotational torque, free state backlash, gear dimensions and external features.

disassembly and cleaning

Disassemble the slewing ring bearing and clean the races, rolling elements and spacers.

Non-destructive testing

Seats are inspected visually or magnetically to detect cracks or defects. Record the hardness reading.

Repairability Assessment

The Restoration Services Department reviews each bearing, application and test results to determine repairability.

Precision grinding

Bearing races are precision ground to the proper geometry to optimize bearing load carrying capacity.

assembly

The bearings are fitted with new rolling elements and seals and filled with lubricant.

final check

All key characteristics are inspected and documented. Bearings are approved by Quality Control prior to shipment.

Remanufacturing

If at any time during the process the repair does not meet Aubearing’s demanding specifications, replacement races or new bearings can be manufactured. Mine operators can realize significant cost savings with our reconditioned slew bearings.

Just as new designs and technologies have improved bearings, growing bearing repair expertise and technology continues to improve the reliability and performance of refurbished bearings, making them an economical alternative to purchasing new bearings.