Bearing Manufacturer & Supplier

Specialize in ball bearings, roller bearings, thrust bearings, thin section bearings etc.

bicycle bearing

There are usually seven places on a bicycle where bearings need to be installed in order for the entire bike to run smoothly. Common components include the center shaft, hub, pedal, head bowl, guide wheel, etc. A bicycle’s performance depends largely on its bearings. And different parts have their suitable bearings.

In order to provide users with a comfortable and safe riding experience, bearings require high precision. Some parts require external sealing protection. Because once water and dirt get into the bearings or use loose bearings, it will cause the wheels to vibrate and make noise when turning.

Table of Contents

ToggleAdvantages of Aubearing bicycle bearings

Our bicycle bearings meet the IATF 16949 automotive industry safety standard. We use 100% automatic testing professional equipment to accurately control the noise value of each bearing. The sealed design of the shell can avoid the intrusion of foreign matter, avoid unnecessary noise, and avoid unnecessary shaking. Therefore, a comfortable and stable riding experience can be provided for the user.

We use high-quality materials and special heat treatment technology to manufacture high-rigidity bearings to make them last longer. These functions can reduce the user’s future losses and provide users with a smoother and safer riding experience. This is why international bicycle manufacturers have been using Aubearing high-precision bearings for many years.

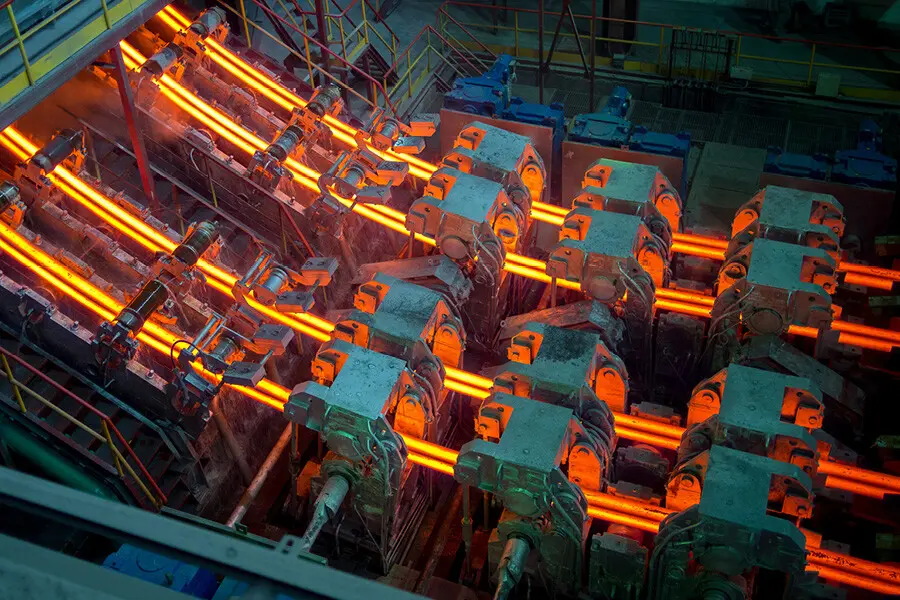

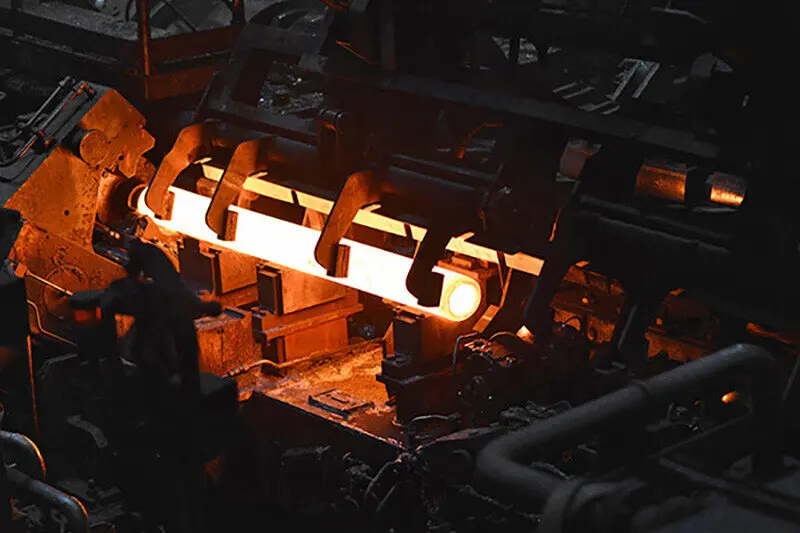

Material properties of bearing steel

Our steel bearings are made from high hardness steel. A professional heat treatment plant can effectively control the steel, increase the toughness and life of the bearing, and have strong impact resistance. Steel bearings are less expensive to replace than ceramic bearings. As long as they are properly cleaned and well lubricated, they are very durable. For this reason, steel bearings are most commonly found in bicycles.

Material properties of ceramic bearings

Compared to steel bearings, ceramic bearings have several key advantages: they are harder, do not rust or corrode, are lighter in weight, are faster, and have a lower coefficient of friction, so only some lubricating oil is required to spin the bearings quickly.

However, the toughness of ceramic bearings is lower than that of steel bearings, so it is easy to break when encountering an impact and produce abnormal noise. In addition, ceramic bearings are expensive to replace. Therefore, this is also the reason why people in the market choose hybrid ceramic bearings.

Hybrid ball bearing

Hybrid ceramic bearings are by far the most popular option in the bike tuning market. Due to the use of anti-collision steel bearings on the outside and ceramics on the inside (no rust and light weight), the advantages of the two materials can be combined to provide bicycle users with a higher quality riding experience. Hybrid ceramic bearings are especially suitable for outdoor muddy and wind and rain erosion environments.

We stock bike bearings for road bikes or mountain bikes to cover different applications. Our thin-section radial ball bearings, often referred to as cartridge bearings, can be used as bottom bracket bearings or bike wheel bearings (hub bearings) and are available with metal shields, rubber contact seals or our “2RU” rubber low friction seals. For greater corrosion resistance, we can supply these in stainless steel and with waterproof lubricants.

Aubearing use high quality hardened chromium steel or 440 grade stainless steel for longer life along with the smoothness and low friction normally associated with their bearings. The standard lubricant in shielded or sealed bearings is a water-resistant, hard-wearing lithium grease but we can also relubricate with a totally waterproof marine grade grease.